okt . 01, 2024 17:39 Back to list

Customized Diaphragm Seal Pressure Gauges for Precise Measurement Solutions in Industrial Applications

Understanding Customized Diaphragm Seal Pressure Gauges in China

In industrial applications, the measurement of pressure is critical for ensuring the safety, efficiency, and reliability of processes. Among the various types of pressure measurement devices, diaphragm seal pressure gauges have emerged as highly effective solutions. In China, the demand for customized diaphragm seal pressure gauges is on the rise, driven by diverse industry requirements and unique operational conditions.

What is a Diaphragm Seal Pressure Gauge?

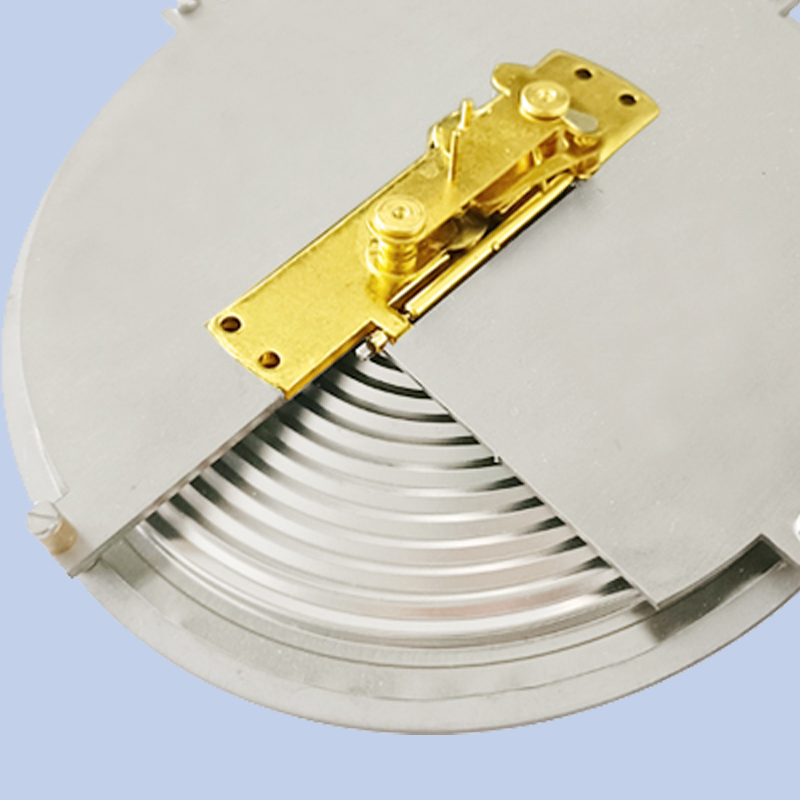

A diaphragm seal pressure gauge consists of a pressure gauge connected to a diaphragm seal that isolates the measuring element from the process media. This design protects the gauge from corrosive, viscous, or particulate-laden fluids, preventing contamination and damage. The diaphragm responds to pressure changes in the process medium, transmitting the pressure to the gauge, which provides accurate readings.

Importance of Customization

Customization is a key factor when it comes to diaphragm seal pressure gauges. Different industries have varying requirements based on the nature of the media being measured, the operational environment, and the specific applications. The following are several reasons why customized diaphragm seal pressure gauges are essential

1. Compatibility with Process Media Industries such as petrochemicals, pharmaceuticals, and food processing often deal with aggressive or sensitive fluids. Customized diaphragm seals can be made from specific materials, such as stainless steel or PTFE, which can resist corrosion and ensure that the integrity of the process is maintained.

2. Adaptation to Extreme Conditions Many industrial processes involve extreme temperatures, pressures, or combinations thereof. Customized gauges can be designed to withstand these conditions, ensuring accurate pressure readings even in the most challenging environments.

3. Size and Configuration Different applications may require gauges of various sizes and configurations. Customized solutions can be designed to fit specific installation spaces or to accommodate unique piping systems, improving efficiency and ease of use.

china customized diaphragm seal pressure gauge

4. Enhanced Accuracy and Reliability By tailoring the diaphragm seal design to the specific needs of an application, users can achieve enhanced accuracy and reliability in their pressure measurements. Customized gauges can minimize errors caused by fluid dynamics or temperature fluctuations.

5. Enterprise Integration In many cases, industries are looking for pressure measurement solutions that seamlessly integrate into their existing systems. Customization allows for features such as digital interfaces, alarm systems, or remote monitoring capabilities that can enhance overall system performance.

Manufacturing Landscape in China

China has developed a robust manufacturing ecosystem for pressure gauges, with numerous companies specializing in the production of diaphragm seal pressure gauges. Leveraging advanced technologies, these manufacturers can offer a range of customization options, from material selection to design specifications.

Chinese manufacturers not only focus on meeting local demand but are also exporting their products globally. The combination of quality production processes, competitive pricing, and a growing emphasis on research and development positions China as a leader in the diaphragm seal pressure gauge market.

Quality Assurance and Standards

As with any industrial equipment, the quality of diaphragm seal pressure gauges is paramount. Chinese manufacturers adhere to international standards such as ISO 9001 to ensure quality management systems are in place. Furthermore, many companies also seek certifications such as CE or ASME to demonstrate compliance with stringent safety and performance regulations.

Conclusion

Customized diaphragm seal pressure gauges are vital for industries in need of reliable pressure measurement solutions. In China, the ability to tailor these instruments to meet specific requirements enhances their usability across various applications. As the demand grows, manufacturers are well-poised to deliver high-quality products that meet both local and international standards. With continued advancements in technology and materials, the future looks bright for diaphragm seal pressure gauges in the global market.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025