aug . 18, 2024 12:06 Back to list

Choosing the Right Type of Differential Pressure Gauge for Your Needs

Understanding Buy Differential Pressure Gauge Types

Differential pressure gauges are essential instruments used in various industries to measure the difference in pressure between two points in a system. This measurement is critical for ensuring that processes operate efficiently and safely. When considering the purchase of a differential pressure gauge, it is important to understand the different types available, their applications, and how to choose the right one for your needs.

Types of Differential Pressure Gauges

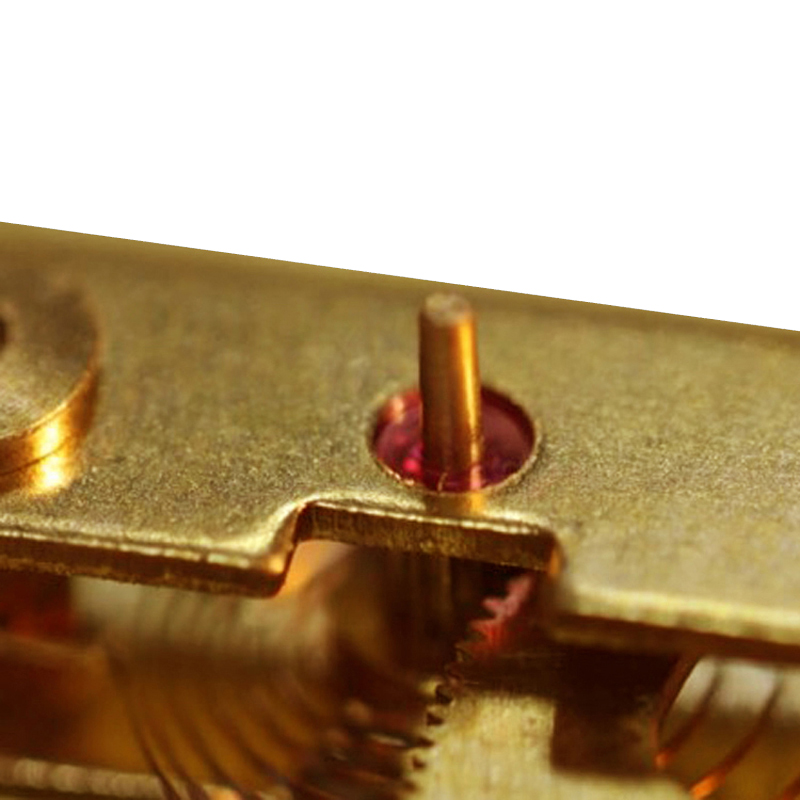

1. Mechanical Differential Pressure Gauges These are the simplest form of differential pressure measurement. They typically use a diaphragm or a capsule that flexes in response to pressure changes. Mechanical gauges are favored for their straightforward design and reliability. They are commonly used in HVAC systems, filtration processes, and various industrial applications where electrical components may be unsuitable.

2. Electronic Differential Pressure Gauges In contrast to mechanical gauges, electronic gauges employ sensors and transducers to detect pressure differences. They often provide more accurate readings and can offer digital outputs for integration with automated systems. Electronic gauges are ideal for applications requiring high precision, such as cleanroom environments and complex manufacturing processes.

3. Capacitive Differential Pressure Gauges These gauges utilize capacitance change between two plates to measure pressure differences. They are notable for their accuracy and sensitivity to small pressure changes. Capacitive gauges are frequently used in laboratories and high-tech industries where precision is paramount.

4. Piezoelectric Differential Pressure Gauges These gauges operate using piezoelectric materials that generate voltage in response to pressure changes. They are excellent for dynamic pressure measurements and can respond rapidly to changes. Consequently, piezoelectric gauges are often used in gas analysis and combustion monitoring applications.

Key Factors to Consider When Buying

When purchasing a differential pressure gauge, consider the following factors

buy differential pressure gauge type

- Application Identify the specific process or application where the gauge will be utilized. Different applications have varying requirements for accuracy, range, and environmental resistance.

- Measurement Range Consider the expected range of pressure differences you need to measure. Select a gauge that can comfortably measure the lowest and highest pressure differentials you anticipate.

- Medium Compatibility Ensure that the materials used in the gauge are compatible with the fluids or gases being measured. Corrosive substances may require specialized materials for the gauge’s construction.

- Environment Evaluate the environmental conditions where the gauge will be installed. Consider factors such as temperature, humidity, and the presence of dust or other contaminants. Some gauges are designed for harsh conditions and may need additional protection.

- Calibration and Maintenance Understand the calibration requirements of the gauge you are considering. Some gauges may require regular calibration to ensure accuracy, which can impact your maintenance schedule and costs.

- Budget Finally, consider your budget. There are differential pressure gauges available at various price points. Determine the best balance between cost and features based on your specific needs.

Conclusion

Differential pressure gauges are vital tools across many industries, helping to monitor, control, and optimize various processes. By understanding the types of gauges available, their specific applications, and important purchasing factors, you can select the right gauge for your needs. Whether you opt for mechanical or electronic, the right differential pressure gauge will enhance your ability to maintain efficient, safe, and accurate operations. Investing in quality instruments tailored to your applications will ultimately yield better performance and reliability in the long run.

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025