jan . 14, 2025 10:40 Back to list

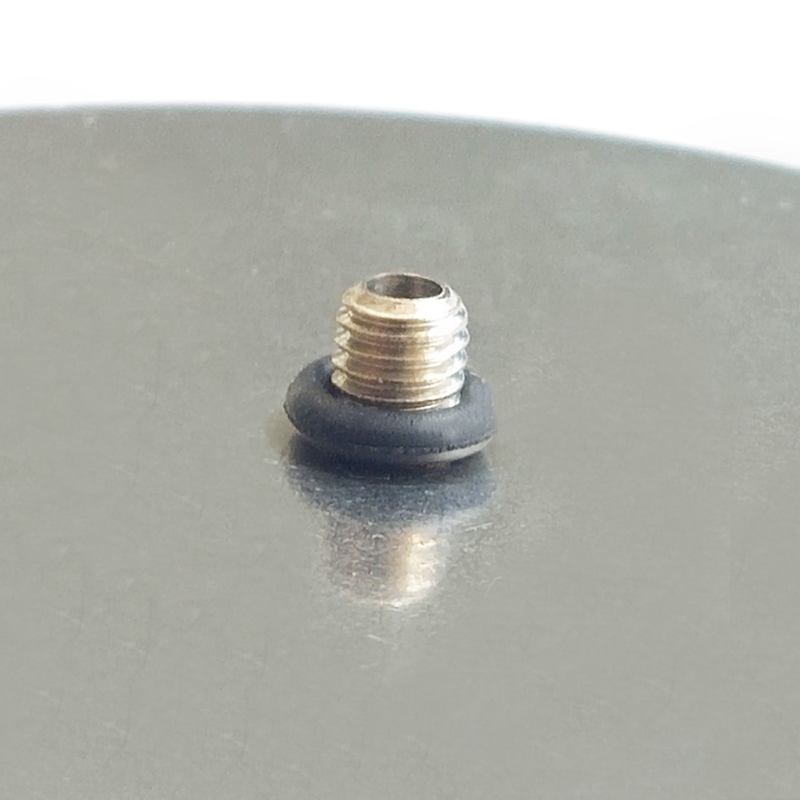

diaphragm sealed pressure gauges

Diaphragm sealed pressure gauges are a critical component in various industrial applications where measuring pressure accurately and safely is paramount. These instruments stand out by incorporating a diaphragm as a protective barrier, making them suitable for environments where conventional pressure gauges might fail.

The authoritativeness of diaphragm sealed pressure gauges is underscored by their widespread acceptance and use in high-stakes settings. Renowned manufacturers and standards organizations have developed guidelines to ensure that these instruments meet rigorous industry standards. For instance, adhering to the standards set by the American Petroleum Institute (API) or the International Organization for Standardization (ISO) assures users of a product's reliability and safety. This certification reaffirms the product's credibility, aiding engineers and technicians in making informed decisions about their pressure measurement needs. Trustworthiness in diaphragm sealed pressure gauges is further enhanced through continuous advancements in design and technology. Modern gauges often feature advanced diaphragm protection technologies and enhanced fluid isolation techniques. These innovations ensure that even in the most challenging environments, the gauges provide consistent, reliable readings. Users should look for products from reputable manufacturers known for their commitment to quality and innovation in pressure measurement technology. In summary, diaphragm sealed pressure gauges offer an ideal solution for industries requiring precise and reliable pressure measurements in challenging environments. Their design, material construction, and adherence to industry standards present them as a trustworthy choice. For entities looking to invest in new pressure measurement technologies, focusing on these aspects—expertise, authoritativeness, and trustworthiness—can lead to superior performance and longevity in their installations.

The authoritativeness of diaphragm sealed pressure gauges is underscored by their widespread acceptance and use in high-stakes settings. Renowned manufacturers and standards organizations have developed guidelines to ensure that these instruments meet rigorous industry standards. For instance, adhering to the standards set by the American Petroleum Institute (API) or the International Organization for Standardization (ISO) assures users of a product's reliability and safety. This certification reaffirms the product's credibility, aiding engineers and technicians in making informed decisions about their pressure measurement needs. Trustworthiness in diaphragm sealed pressure gauges is further enhanced through continuous advancements in design and technology. Modern gauges often feature advanced diaphragm protection technologies and enhanced fluid isolation techniques. These innovations ensure that even in the most challenging environments, the gauges provide consistent, reliable readings. Users should look for products from reputable manufacturers known for their commitment to quality and innovation in pressure measurement technology. In summary, diaphragm sealed pressure gauges offer an ideal solution for industries requiring precise and reliable pressure measurements in challenging environments. Their design, material construction, and adherence to industry standards present them as a trustworthy choice. For entities looking to invest in new pressure measurement technologies, focusing on these aspects—expertise, authoritativeness, and trustworthiness—can lead to superior performance and longevity in their installations.

Share

Latest news

-

Fluke Differential Pressure Gauges Precision Instruments for Industrial Use

NewsMay.25,2025

-

WIKA Differential Pressure Gauge 700.01 - High Accuracy & Durable Design

NewsMay.25,2025

-

Diaphragm Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.25,2025

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025