aug . 07, 2024 13:50 Back to list

Differential Pressure Gauge with Needle Indicator for Efficient Water Filter Factory Monitoring

Understanding Differential Pressure Gauges with Needle Indicators for Water Filter Applications

In the realm of water filtration, maintaining optimal flow and ensuring the effectiveness of filtration systems is crucial. One of the key tools employed in these applications is the differential pressure gauge, particularly those equipped with needle indicators. This article explores the significance, functionality, and benefits of differential pressure gauges, specifically for water filter factories.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points in a system. In water filtration setups, this typically involves assessing the pressure before and after a filter. The data provided by such gauges is critical in determining the operational status of filters, ensuring they are working efficiently.

Importance in Water Filtration

Water filters are designed to remove impurities and contaminants from water. Over time, however, filters can become clogged with these particulates, leading to increased pressure and decreased filtration efficiency. By using a differential pressure gauge, operators can monitor the pressure drop across the filter. A significant pressure differential indicates that the filter needs maintenance, whether it requires cleaning or replacement.

Needle Indicators Precision and Clarity

Differential pressure gauges with needle indicators feature a dial with a needle that precisely points to the pressure reading. This visual representation is beneficial for operators who require immediate feedback on system performance. The needle can quickly show changes in pressure, allowing for real-time adjustments and prompting necessary actions to maintain system efficiency.

Needle indicators often offer a wider range of measurement and better resolution than digital displays, especially in conditions where rapid fluctuations occur. The simplicity of analog readings can sometimes be easier to interpret, especially for those who may not be familiar with digital devices.

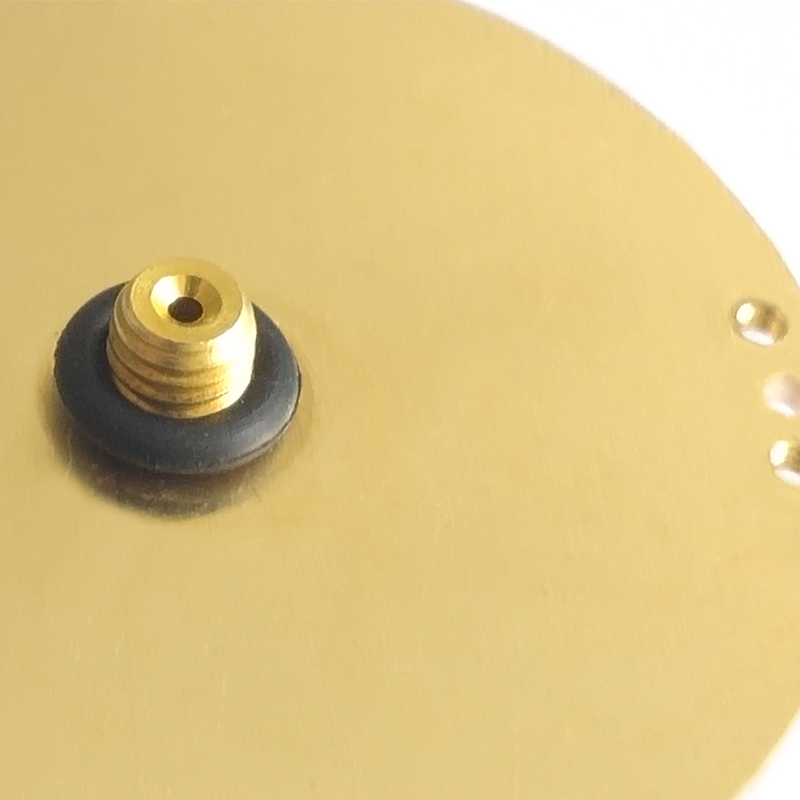

differential pressure gauge with needle for water filter factory

Benefits of Using Differential Pressure Gauges in Water Filter Factories

1. Efficiency Monitoring Regular monitoring of differential pressure helps ensure that filters operate within their optimal parameters. This can lead to better overall system efficiency and reduced operational costs by preventing overworking of pumps and shortening filter lifespan.

2. Preventative Maintenance By identifying potential issues early through pressure changes, filtration systems can be maintained proactively. This preventative approach avoids costly downtimes and ensures consistent filtration quality.

3. Improved Water Quality Maintaining the appropriate pressure levels ensures that water quality remains high, which is vital for downstream applications. For water treatment facilities, this is crucial since they must meet strict quality standards.

4. User-Friendly Differential pressure gauges with needle indicators are often designed for ease of use. They require minimal training for personnel, making it easier to integrate them into various water filtration processes.

5. Cost-Effectiveness Investing in differential pressure gauges is generally seen as a cost-effective measure. They allow for immediate detection of potential issues without the need for extensive and costly monitoring equipment.

Conclusion

Differential pressure gauges with needle indicators play a pivotal role in the operations of water filter factories. They provide critical data that helps maintain efficiency, ensure water quality, and facilitate proactive maintenance strategies. By integrating these gauges into filtration systems, operators can achieve better performance, reduce costs, and ultimately deliver superior water quality to consumers. As the demand for clean water continues to rise, the importance of effective monitoring tools like differential pressure gauges becomes increasingly evident.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025