nov . 22, 2024 05:17 Back to list

differential pressure gauge kit factories

Understanding Differential Pressure Gauge Kit Factories

Differential pressure gauges are essential instruments used in various industries to measure the pressure difference between two points. This technology plays a crucial role in applications such as HVAC systems, pharmaceutical manufacturing, and municipal water systems, where accurate pressure measurements are vital for maintaining system efficiency and safety. As a result, the factories that produce differential pressure gauge kits are pivotal in ensuring that these devices meet industry standards and customer demands.

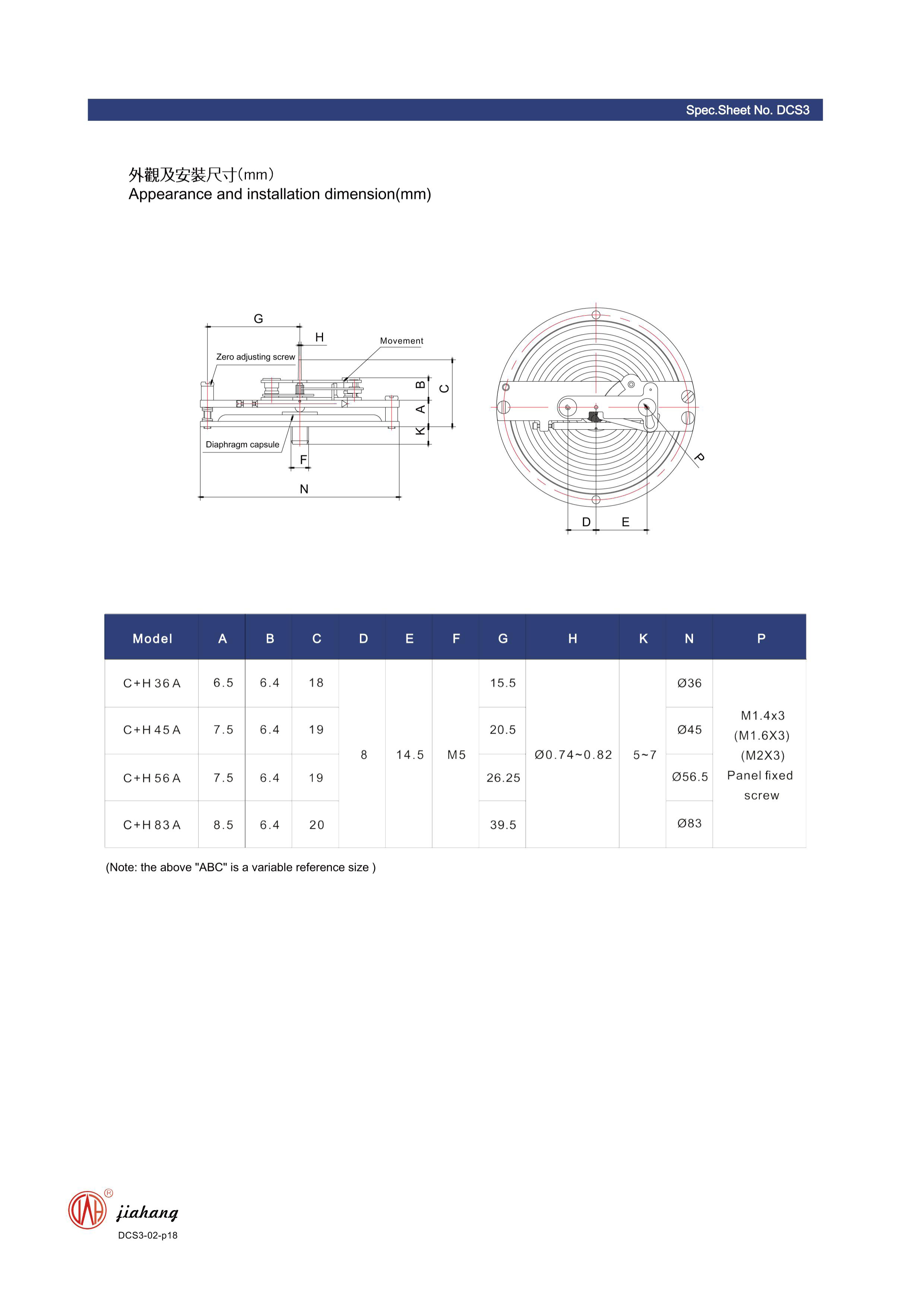

At the heart of differential pressure gauge manufacturing is the technology employed to measure the differences in pressure. These gauges typically consist of a sensing element, a display mechanism, and a way to transmit the measurement data. Manufacturers focus on precision engineering, utilizing high-grade materials to ensure the durability and longevity of their products. Common materials include stainless steel, which is resistant to corrosion and able to withstand different environmental conditions.

In the fabrication process, quality control is paramount. Manufacturers implement rigorous testing protocols at various stages to ensure that each gauge will perform accurately under the specified conditions. This involves not only testing the gauges under standard operating conditions but also subjecting them to extreme pressures and temperatures to guarantee reliability. These quality assurance processes help build trust with customers who depend on accurate readings for crucial operations.

The rise of automation and modern manufacturing techniques has led to enhanced efficiency in differential pressure gauge kit production. Factories now utilize computer-aided design (CAD) software and advanced manufacturing technologies such as CNC machining. These innovations not only streamline the production process but also allow for more complex designs that can provide additional functionality, such as digital displays and remote monitoring capabilities. This evolution in manufacturing practices enables factories to produce more sophisticated and user-friendly pressure measurement tools.

differential pressure gauge kit factories

Furthermore, the demand for differential pressure gauges has been influenced by the growing focus on energy efficiency and environmental sustainability across industries. Producers have responded by creating products that help in monitoring and optimizing energy consumption. Differential pressure gauges can help detect blockages or leaks in systems, allowing for timely maintenance actions that reduce waste and improve system performance.

Another significant aspect of differential pressure gauge kit manufacturing is customization. Different industries have unique requirements based on specific operational needs. Consequently, manufacturers often offer customizable solutions, allowing clients to select features, sizes, and specifications that suit their applications best. This flexibility often enhances customer satisfaction and loyalty, as businesses are provided with tailored solutions that fit their exact requirements.

In addition to domestic markets, many factories are also expanding their reach globally. With international standards becoming more pronounced in various industries, manufacturers are increasingly ensuring that their products comply with global regulations. This attentiveness to international standards not only opens up new markets but also promotes best practices in manufacturing and design.

As industries continue to evolve, the role of differential pressure gauge kit factories will remain critical. These manufacturers not only supply necessary tools for various applications but also innovate to meet future demands, ensuring that their products are both reliable and advanced. By combining quality craftsmanship, technological innovation, and customer-centric solutions, differential pressure gauge kit factories are laying the groundwork for a more efficient and safe industrial landscape. In an age where precise measurements are crucial, the importance of these manufacturers will only grow, highlighting their role in sustaining and enhancing operational effectiveness across multiple sectors.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025