feb . 17, 2025 12:31 Back to list

digital pressure gauge components

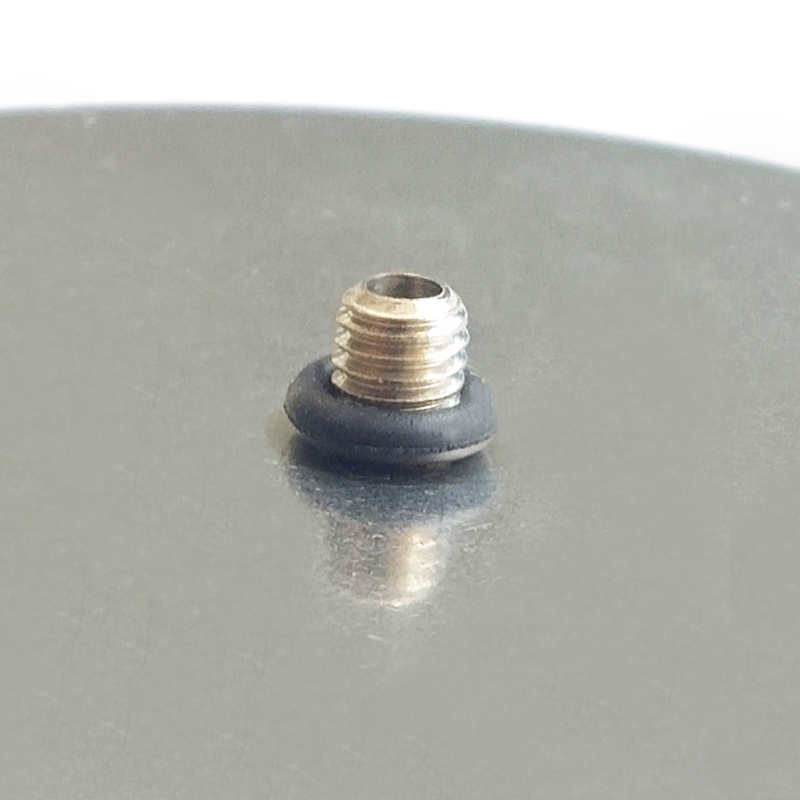

High quality digital pressure gauge components are essential for precision, reliability, and long-lasting performance in various industrial applications. When selecting a digital pressure gauge, it is crucial to focus on the components that determine the gauge’s overall performance. This article explores the key components, emphasizing their importance in ensuring accuracy and durability, while also highlighting their role in gaining an authoritative edge in the highly competitive digital pressure gauge market.

Battery life and power management components also contribute significantly to the device's reliability and user trustworthiness. High-quality digital pressure gauges are equipped with efficient power management systems to optimize battery life. Some are designed with low-power modes and configurable auto-shutdown features, dramatically extending operational life without compromising performance. An authoritative gauge should also incorporate power-saving mechanisms that maintain accuracy and responsiveness. Connectivity options mark the frontier of modern digital pressure gauge capabilities. As industries move towards smart manufacturing, the ability to remotely monitor and control devices becomes paramount. High-quality gauges provide connectivity through wireless communications such as Bluetooth, Wi-Fi, or even more sophisticated IoT platforms. This integration allows for seamless data transfer and real-time monitoring, enabling enhanced predictive maintenance and operational efficiency. Precision, design, and durability are critical to the selection of components in a digital pressure gauge, but so is the commitment to continuous improvement and innovation. Leading manufacturers invest in research and development to refine their components continually, ensuring that they stay ahead of technological advancements and industry standards. This pursuit of excellence not only fosters trust among consumers but also establishes a heritage of quality and safety. Ultimately, when aiming for a high-quality digital pressure gauge, it's imperative to understand how each component functions and contributes to its overall operation. From the sensitive pressure sensors to the intuitive displays and robust housings, each part plays a definitive role in the gauge's performance. By ensuring that these components meet the highest standards of precision and reliability, manufacturers can deliver a product that not only satisfies but exceeds the expectations of industrial professionals, cementing their status as leaders in the field.

Battery life and power management components also contribute significantly to the device's reliability and user trustworthiness. High-quality digital pressure gauges are equipped with efficient power management systems to optimize battery life. Some are designed with low-power modes and configurable auto-shutdown features, dramatically extending operational life without compromising performance. An authoritative gauge should also incorporate power-saving mechanisms that maintain accuracy and responsiveness. Connectivity options mark the frontier of modern digital pressure gauge capabilities. As industries move towards smart manufacturing, the ability to remotely monitor and control devices becomes paramount. High-quality gauges provide connectivity through wireless communications such as Bluetooth, Wi-Fi, or even more sophisticated IoT platforms. This integration allows for seamless data transfer and real-time monitoring, enabling enhanced predictive maintenance and operational efficiency. Precision, design, and durability are critical to the selection of components in a digital pressure gauge, but so is the commitment to continuous improvement and innovation. Leading manufacturers invest in research and development to refine their components continually, ensuring that they stay ahead of technological advancements and industry standards. This pursuit of excellence not only fosters trust among consumers but also establishes a heritage of quality and safety. Ultimately, when aiming for a high-quality digital pressure gauge, it's imperative to understand how each component functions and contributes to its overall operation. From the sensitive pressure sensors to the intuitive displays and robust housings, each part plays a definitive role in the gauge's performance. By ensuring that these components meet the highest standards of precision and reliability, manufacturers can deliver a product that not only satisfies but exceeds the expectations of industrial professionals, cementing their status as leaders in the field.

Share

Latest news

-

Diaphragm Type Differential Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.17,2025

-

Bellow Type Differential Pressure Gauge High Accuracy & Durable Design

NewsMay.17,2025

-

WIKA 700.04 Differential Pressure Gauge Precision Industrial Measurement

NewsMay.17,2025

-

Fire Extinguisher Pressure Gauge Manufacturers Reliable & Certified Suppliers

NewsMay.16,2025

-

Isolation Diaphragm Pressure Gauges High-Precision & Durable Solutions

NewsMay.16,2025

-

Premium Pressure Gauge Precision Instruments Reliable & Durable Solutions

NewsMay.16,2025