okt . 14, 2024 21:40 Back to list

odm pressure gauge with diaphragm

Understanding ODM Pressure Gauges with Diaphragm Technology

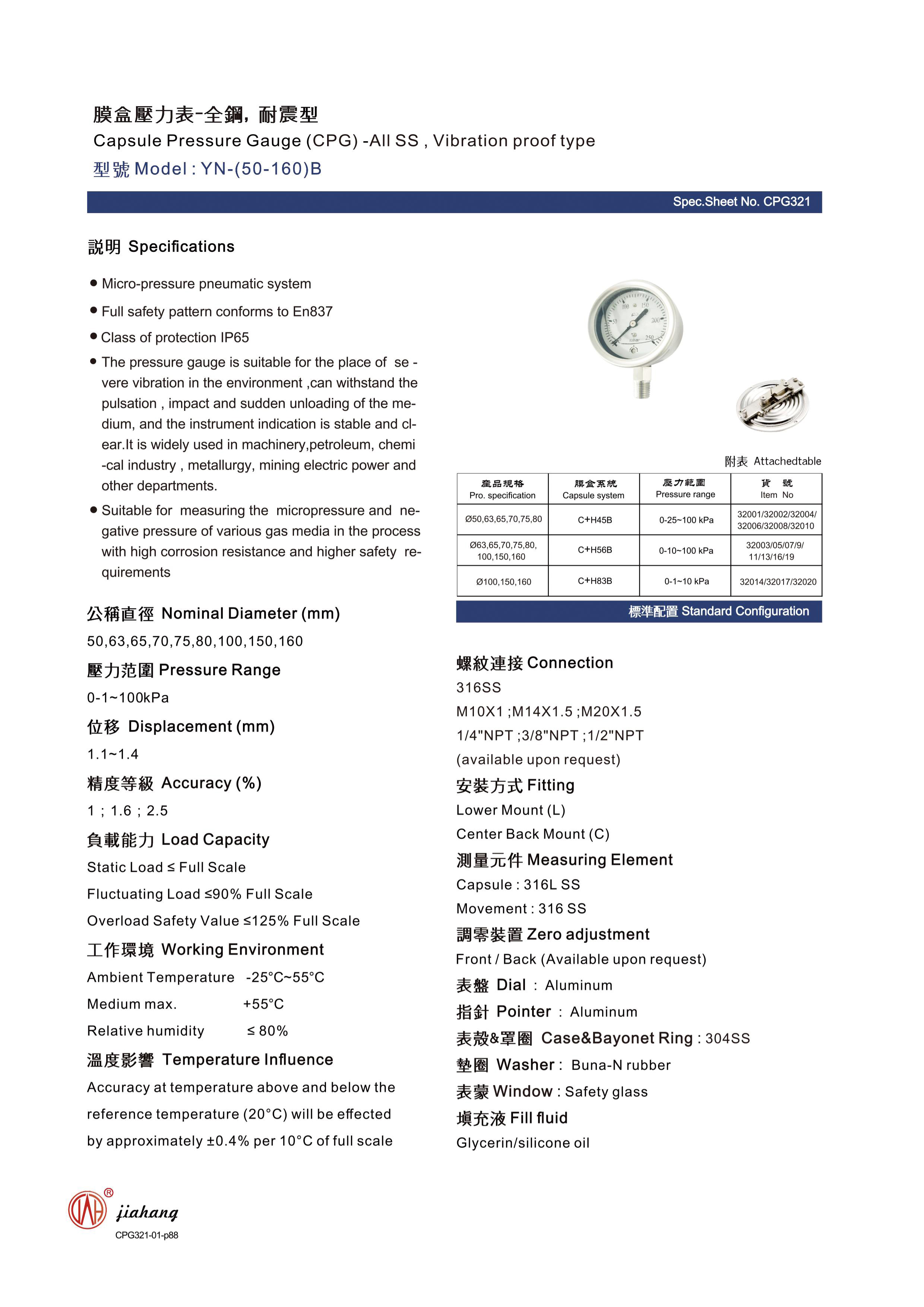

Pressure gauges are crucial instruments in various industries, as they measure the pressure of gases and liquids. Among the different types of pressure gauges available, ODM (Original Design Manufacturer) pressure gauges with diaphragm technology have gained significant attention due to their robustness, accuracy, and versatility. This article will explore the features, benefits, and applications of ODM pressure gauges with diaphragm systems.

At the heart of a diaphragm pressure gauge is the diaphragm itself, a flexible, membrane-like component that responds to pressure changes. When pressure is applied to one side of the diaphragm, it bends in response to this differential pressure. This movement is then translated into a readable measurement via a mechanical linkage, typically connected to a dial or digital display. The design ensures that the pressure measurement is not only precise but also reflective of the actual operating conditions.

Understanding ODM Pressure Gauges with Diaphragm Technology

OdM manufacturers often provide customizable options, allowing industries to tailor pressure gauges to specific needs. This could include variations in size, diaphragm material, and calibration ranges. Common diaphragm materials include stainless steel, elastomers, and compatible plastics, which enhance the gauge's durability and longevity, even in harsh operating conditions. By collaborating with ODM manufacturers, businesses can ensure that the pressure gauge they use is not only efficient but also meets industry standards and safety regulations.

odm pressure gauge with diaphragm

Another notable feature of diaphragm pressure gauges is their ability to minimize the effects of vibration and pulsation. In many industrial settings, pressure readings can be influenced by external factors such as rapid changes in pressure or movement of equipment. The diaphragm’s design mitigates these disturbances, providing stable and accurate readings, which is crucial for maintaining operations and ensuring safety.

In terms of installation, ODM pressure gauges are designed for easy integration into existing systems. They often come with various mounting options, whether direct mounting or remote installations, which adds to their versatility. This ease of installation means reduced downtime and quick replacement in case of gauge failure, thereby improving overall operational efficiency.

Furthermore, regular maintenance and calibration of these gauges are essential to ensure their long-term performance and accuracy. Many ODM manufacturers provide guidelines and support for maintaining their products, ensuring that businesses can achieve optimal functionality and reliability over time.

In conclusion, ODM pressure gauges with diaphragm technology represent a vital tool in industrial applications requiring accurate pressure measurement. Their robust design, adaptability, and ability to mitigate external influences make them ideal for a wide spectrum of environments. As industries continue to evolve, the need for efficient and reliable pressure measurement will only grow, affirming the value of diaphragm pressure gauges in the modern industrial landscape.

-

HD Fire Pressure Gauges High Accuracy & Durable Solutions

NewsMay.28,2025

-

Custom Singles Capsule Systems Top Exporters & Factories

NewsMay.28,2025

-

Piston-Style Differential Pressure Gauges Precision & Durability

NewsMay.28,2025

-

WIKA Differential Pressure Gauge 700.04 High-Accuracy Industrial Measurement

NewsMay.28,2025

-

Precision Differential Pressure Gauge Factory Custom Solutions & OEM Services

NewsMay.27,2025

-

Pressure Diaphragm Capsule Elements High-Accuracy & Durable Solutions

NewsMay.27,2025