okt . 16, 2024 10:54 Back to list

Diaphragm Pressure Gauge Maintenance and Service Guidelines

Understanding Wika Diaphragm Pressure Gauges Service and Maintenance

Pressure gauges play a critical role in various industrial applications, providing essential measurements that ensure safety and efficiency. Among these gauges, the Wika diaphragm pressure gauge stands out for its unique design and reliability. This article explores the functionalities, advantages, and recommended service practices for sustaining the performance of Wika diaphragm pressure gauges.

What is a Wika Diaphragm Pressure Gauge?

Wika diaphragm pressure gauges are mechanical instruments used to measure the pressure of gases and liquids. They operate based on the principle of a diaphragm, a flexible membrane that deflects in response to pressure changes. When pressure is applied to one side of the diaphragm, it deforms, causing the movement of a pointer on a calibrated dial to display the pressure value. This design minimizes the risk of damage from pulsating or fluctuating pressures, making these gauges ideal for harsh environments and various applications.

Key Advantages of Wika Diaphragm Pressure Gauges

1. High Accuracy Wika gauges are engineered for precision, offering reliable readings even in volatile conditions. This accuracy is crucial for processes that require exact pressure levels.

2. Robust Construction Made from durable materials such as stainless steel, Wika diaphragm gauges can withstand extreme temperatures and corrosive environments. This robustness prolongs the life of the instrument, reducing the need for frequent replacements.

4. Ease of Maintenance With a straightforward calibration process, Wika gauges can be easily maintained. This helps organizations minimize downtime and maintain operational efficiency.

Service and Maintenance of Wika Diaphragm Pressure Gauges

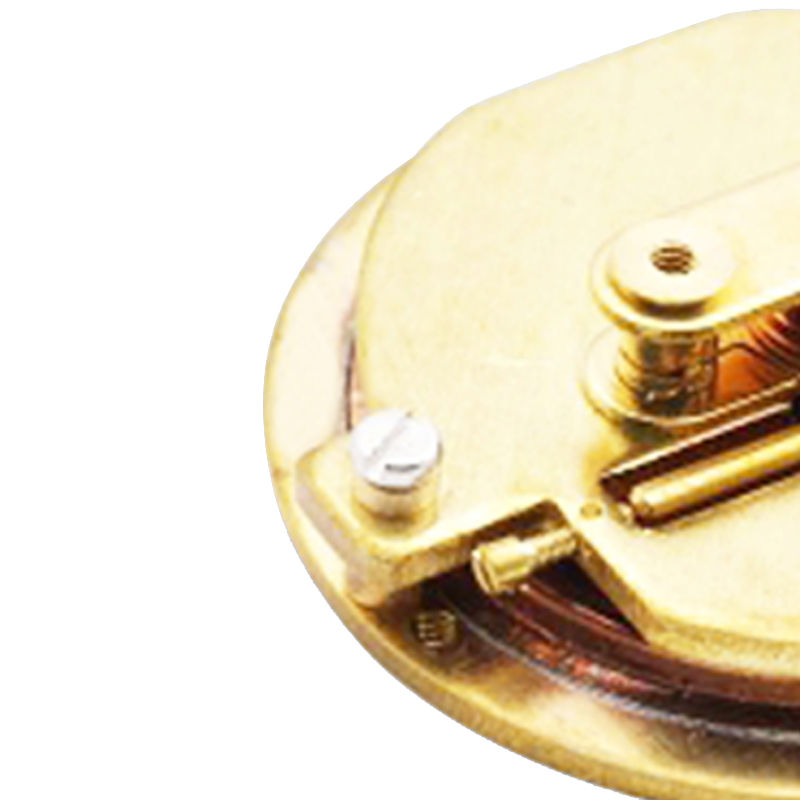

wika diaphragm pressure gauge service

Proper service and maintenance are essential to ensure the longevity and reliability of Wika diaphragm pressure gauges. Here are some key practices

1. Regular Calibration Regular checks against known standards are crucial for maintaining accuracy. Wika recommends calibrating pressure gauges at least once a year, or more frequently in critical applications or harsh environments.

2. Visual Inspections Conduct regular visual inspections for signs of wear, corrosion, or damage to the gauge and its connections. Look for leaks or any obstruction in the diaphragm, as these can significantly impact performance.

3. Clean the Gauge Ensure that the external surfaces of the gauge are kept clean to prevent dirt or contaminants from entering the system. Depending on the application, the internal components may also require periodic cleaning to maintain operational integrity.

4. Check Connections Ensuring that all connections are tight and secure is vital. Loose connections can lead to measurement inaccuracies due to leaks or pressure drops.

5. Environment Considerations Different environments can impact the performance of diaphragm gauges. Consider factors such as temperature fluctuations, humidity, and exposure to chemicals. Appropriate protective enclosures or filters may be necessary for gauges operating in extreme conditions.

6. Documentation Keep a log of maintenance activities, calibration records, and any repairs made to the gauge. This documentation can be invaluable for troubleshooting and ensures that all servicing is performed according to industry standards.

Conclusion

Wika diaphragm pressure gauges are indispensable tools in various industrial applications, known for their accuracy, durability, and versatility. By adhering to recommended service and maintenance procedures, users can enhance the longevity and performance of these instruments. Regular calibration, visual inspections, and environmental considerations are essential to ensure that Wika diaphragm pressure gauges continue to deliver reliable pressure readings, safeguarding both processes and personnel from potential hazards associated with pressure variations. Proper care of these instruments not only ensures operational efficiency but also contributes to overall safety in the workplace.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025