nov . 30, 2024 10:14 Back to list

Differential Pressure Gauges for Accurate Measurement and Monitoring Solutions

Understanding Differential Pressure Gauges Functions, Applications, and Benefits

Differential pressure gauges, commonly known as DP gauges, are essential instruments used to measure the pressure difference between two points within a system. This capability provides critical insights into various industrial processes and is vital in fields such as HVAC (Heating, Ventilation, and Air Conditioning), oil and gas, water treatment, and other applications where pressure monitoring is crucial.

How Differential Pressure Gauges Work

At its core, a differential pressure gauge operates based on the principle of comparing two pressure inputs. The gauge has two ports one that measures the pressure at a given point in the system (high pressure) and another that measures the ambient or reference pressure (low pressure). The difference between these pressures is displayed on the gauge, allowing engineers and operators to determine whether a system is operating within its designated parameters.

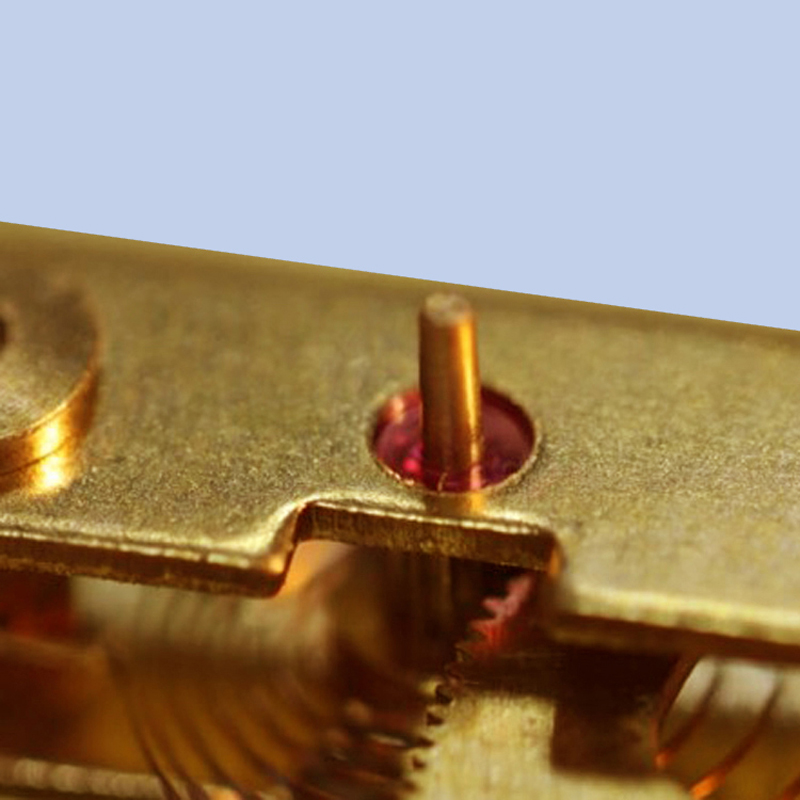

One of the most common methods for measuring differential pressure involves the use of a diaphragm or a capsule. These components flex in response to pressure changes, and this deflection is then converted into an electrical signal or an analog reading that represents the pressure difference.

Various Applications

Differential pressure gauges serve a plethora of applications across various industries

1. HVAC Systems In heating and cooling systems, DP gauges are employed to monitor the pressure drop across filters or coils. This helps maintain optimal airflow and energy efficiency and ensures that the system operates effectively.

2. Pharmaceutical Manufacturing Maintaining the correct pressure differential in cleanrooms is essential for preventing contamination. Differential pressure gauges help monitor these conditions, crucial for adhering to stringent industry standards.

wika differential pressure gauge product

4. Oil and Gas In the extraction and processing of oil and gas, differential pressure gauges can help monitor pipeline systems, ensuring that pressure differences are maintained for optimal flow rates and safety.

5. Chemical Processing Many chemical reactions require precise pressure conditions. Using DP gauges, operators can monitor reactor vessels or columns, ensuring that the pressure remains within the required range.

Advantages of Using Differential Pressure Gauges

1. Precision Measurement Differential pressure gauges provide accurate readings, enabling operators to make informed decisions based on current system conditions. This precision can lead to improved process efficiency and reduced operational costs.

2. Early Fault Detection By consistently monitoring pressure differences, these gauges can help identify potential problems early, such as blockages or leaks, allowing for timely maintenance and reducing downtime.

3. Enhanced Safety In many applications, maintaining the correct pressure is critical for safety. Differential pressure gauges play an essential role in preventing overpressure situations that could lead to equipment failure or hazardous conditions.

4. Versatility Differential pressure gauges can be used in various environments and can be customized to suit specific process requirements. Whether in harsh industrial settings or sensitive cleanroom environments, there’s a gauge designed for every application.

Conclusion

In summary, differential pressure gauges are indispensable tools in modern engineering and industrial processes. Their ability to provide accurate and reliable pressure readings is fundamental to ensuring the efficiency, safety, and longevity of various systems. As technology continues to evolve, we can expect further advancements in pressure measurement technologies, opening up new possibilities for monitoring and controlling industrial processes effectively. Whether for maintaining HVAC systems, ensuring pharmaceutical manufacturing standards, or optimizing chemical processes, the importance of differential pressure gauges cannot be overstated.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025