Okt . 15, 2024 03:44 Back to list

capillary diaphragm seal pressure gauge quotes

Understanding Capillary Diaphragm Seal Pressure Gauges

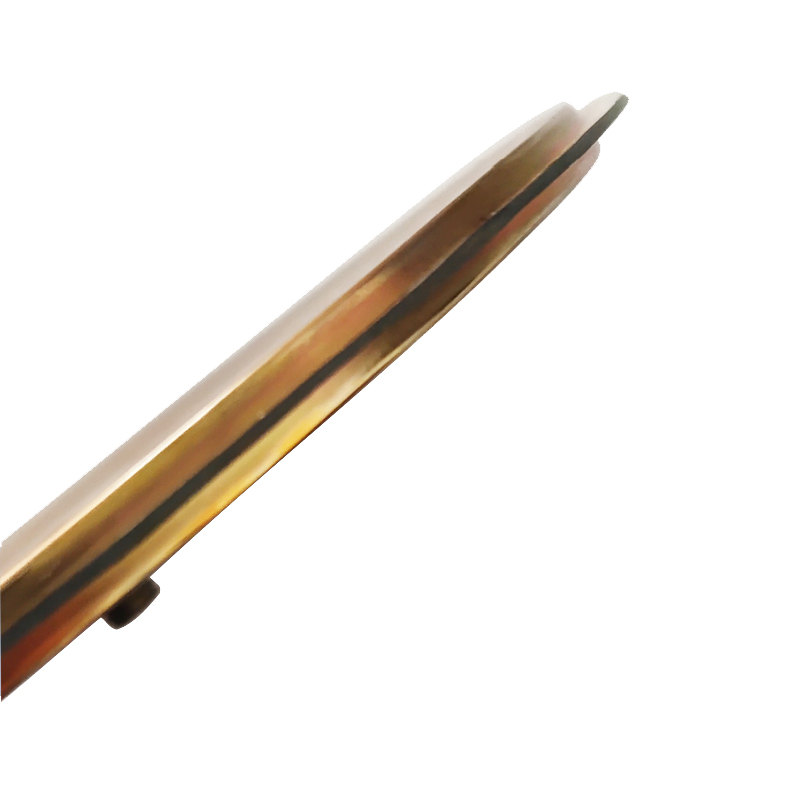

Capillary diaphragm seal pressure gauges are indispensable instruments in various industrial applications, especially in environments where traditional pressure measurement tools may fail due to extreme conditions. These gauges are designed to measure pressure in locations where direct contact with the process fluid is not feasible or safe.

The primary function of a diaphragm seal is to isolate the measuring element from the process fluid. This is crucial in scenarios where the fluid is corrosive, viscous, or contains particulates that could lead to gauge malfunction or damage. The diaphragm acts as a barrier, transmitting pressure to the gauge while ensuring that the internal components remain unaffected by the process conditions.

One of the standout features of capillary diaphragm seals is the use of a flexible capillary tube that connects the diaphragm seal to the pressure gauge. This design allows for the measurement of pressure even from remote locations. This capability is particularly useful in applications such as chemical processing, pharmaceuticals, and oil and gas industries, where the pressure source might be located in hazardous or hard-to-reach areas.

capillary diaphragm seal pressure gauge quotes

When choosing capillary diaphragm seal pressure gauges, several factors come into play. The material of the diaphragm is crucial, as it must withstand the process fluid's properties without degrading over time. Common materials include stainless steel, Hastelloy, and Teflon, each tailored to specific applications based on compatibility and performance requirements.

Another critical aspect to consider is the fill fluid used within the capillary system. The fill fluid not only transmits pressure but also influences the gauge's response time and sensitivity. Common fill fluids include glycerine, silicone oil, and mineral oils, each chosen based on temperature range and environmental conditions.

Proper installation and maintenance of diaphragm seal pressure gauges are essential to ensure accurate readings and longevity. Regular calibration and inspection can prevent the accumulation of dirt or particulates that could introduce error into the measurements.

Ultimately, the effective application of capillary diaphragm seal pressure gauges can enhance safety and reliability in process control. By isolating the measuring elements from harsh environments, these gauges offer invaluable precision and durability, making them a trusted choice for industries that demand accurate and consistent pressure readings.

-

Fluke Differential Pressure Gauges Precision Instruments for Industrial Use

NewsMay.25,2025

-

WIKA Differential Pressure Gauge 700.01 - High Accuracy & Durable Design

NewsMay.25,2025

-

Diaphragm Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.25,2025

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025