Nov . 05, 2024 23:26 Back to list

Custom Differential Pressure Gauge with Diaphragm Seal for Accurate Measurement Applications

Custom Differential Pressure Gauge with Diaphragm Seal An Overview

In various industrial applications, precise measurement of pressure differentials is crucial for ensuring optimal performance and safety. A custom differential pressure gauge with a diaphragm seal is an essential instrument designed to address these needs. In this article, we will explore the key features, benefits, applications, and considerations associated with using this specialized gauge.

Understanding Differential Pressure Gauges

Differential pressure gauges are devices that measure the difference in pressure between two points in a system. This measurement is vital in numerous applications, including filtration systems, process control, and HVAC systems. By determining how much pressure drop occurs, these gauges can help monitor system performance, detect blockages, and ensure efficient operation.

The Role of Diaphragm Seals

The diaphragm seal in a differential pressure gauge acts as a barrier between the process media and the internal sensing element of the gauge. This design is particularly useful for protecting the gauge from harsh environments, corrosive fluids, viscous materials, and high-pressure applications. The diaphragm transmits the pressure from the fluid on one side to a sensing component, enabling accurate measurements while safeguarding the gauge's internal mechanisms.

Customization for Specific Needs

One of the standout features of a custom differential pressure gauge with a diaphragm seal is its adaptability to specific application requirements. Customization can involve various aspects, including

1. Material Selection Depending on the process media and environmental conditions, the materials used for the diaphragm and casing can be tailored. For example, PTFE, stainless steel, or even exotic alloys can be selected for enhanced corrosion resistance and durability.

2. Pressure Range Gauges can be designed to measure varying pressure ranges, ensuring that they are suitable for both low and high-pressure applications.

3. Size and Configuration The physical dimensions, mounting options, and configurations can be modified to fit particular installations. This flexibility allows for seamless integration into existing systems.

4. Electrical Output Custom gauges can be equipped with various output options, such as analog signals or digital communication protocols like 4-20 mA, MODBUS, or HART, enabling easy integration into automated systems.

custom differential pressure gauge with diaphragm seal

Benefits of Using a Custom Differential Pressure Gauge

1. Enhanced Accuracy By accounting for the specific conditions of an application, customized gauges can provide more reliable and accurate measurements, which is vital for maintaining system integrity.

2. Increased Longevity Custom gauges designed with appropriate materials and features can withstand harsh environments, leading to reduced wear and tear, thereby extending the lifespan of the instrument.

3. Improved Safety A well-designed diaphragm seal prevents the contamination of the sensing elements and protects the operator from potentially hazardous process media.

4. Streamlined Operations Accurate pressure differential readings enable more efficient system operations, minimizing downtime and maintenance costs.

5. Tailored Solutions Customization allows industries to address unique challenges directly, enhancing overall productivity.

Applications

Custom differential pressure gauges with diaphragm seals are widely used across various industries, including

- Oil and Gas Monitoring pressure differentials in pipelines and separators. - Pharmaceuticals Ensuring hygiene and maximizing accuracy in sterile environments. - Water Treatment Tracking the effectiveness of filtration systems. - HVAC Regulating air flow and maintaining indoor air quality.

Conclusion

A custom differential pressure gauge with a diaphragm seal is a pivotal tool in modern industry, facilitating accurate pressure measurement in challenging environments. By allowing for tailored specifications and adaptations, these gauges not only enhance measurement precision but also improve safety and operational efficiency. As various sectors continue to evolve, customized solutions will remain crucial for meeting the demands of complex pressure monitoring applications.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

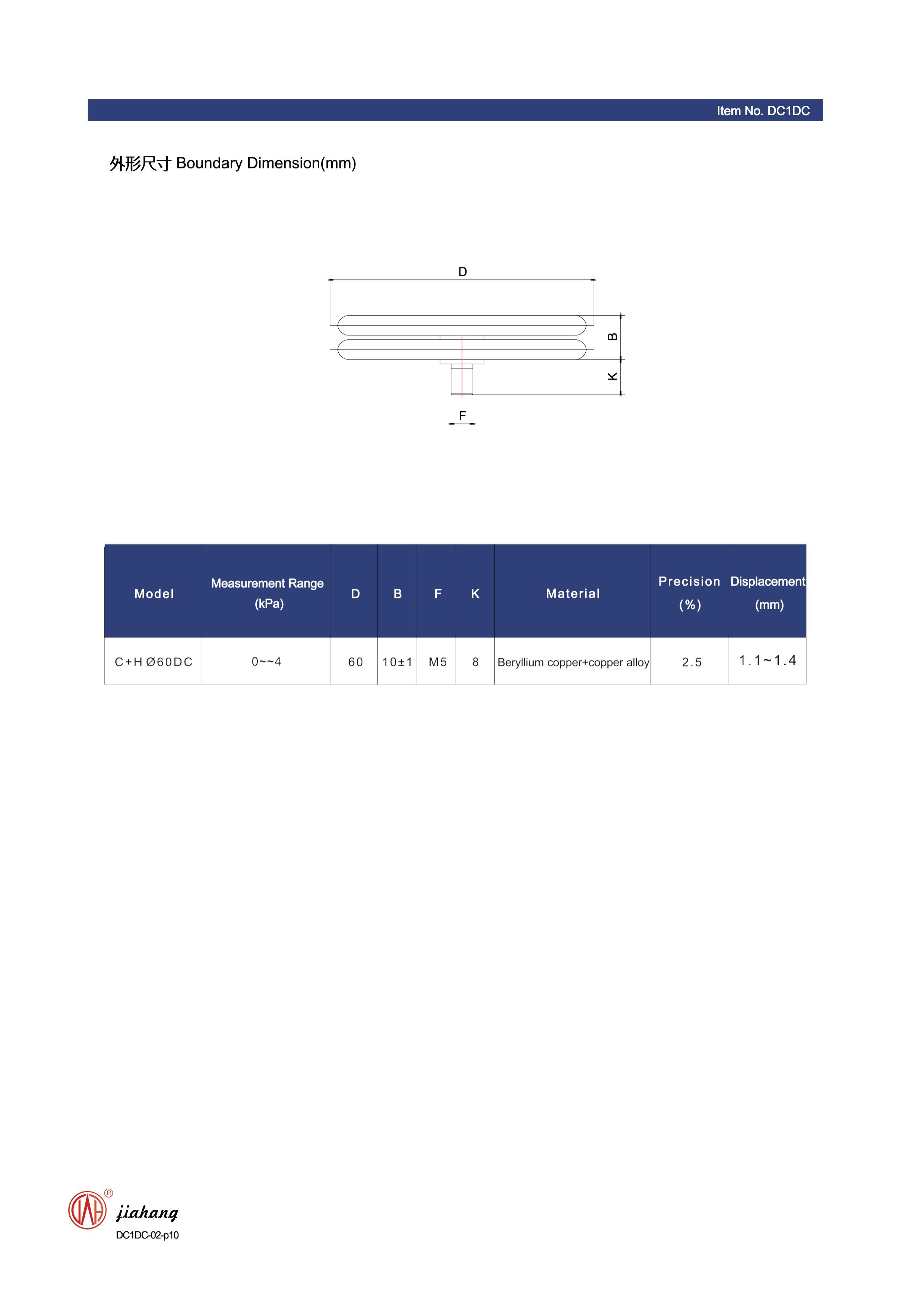

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025