Jun . 11, 2024 16:27 Back to list

Customized diaphragm pressure sensing component

Understanding the Custom Diaphragm Pressure Element A Key Component in Modern Engineering

In the realm of engineering and instrumentation, the custom diaphragm pressure element stands as a critical component, playing an essential role in various industries such as oil and gas, pharmaceuticals, and process control systems. This specialized device is designed to convert applied pressure into measurable mechanical deformation, thereby providing accurate and reliable pressure readings.

A diaphragm pressure element, essentially, is a flexible membrane that separates two chambers, with one side exposed to the process fluid or gas, and the other side connected to a measuring instrument. The deflection of the diaphragm due to the pressure differential across it is translated into a proportional output signal, which can be read and analyzed.

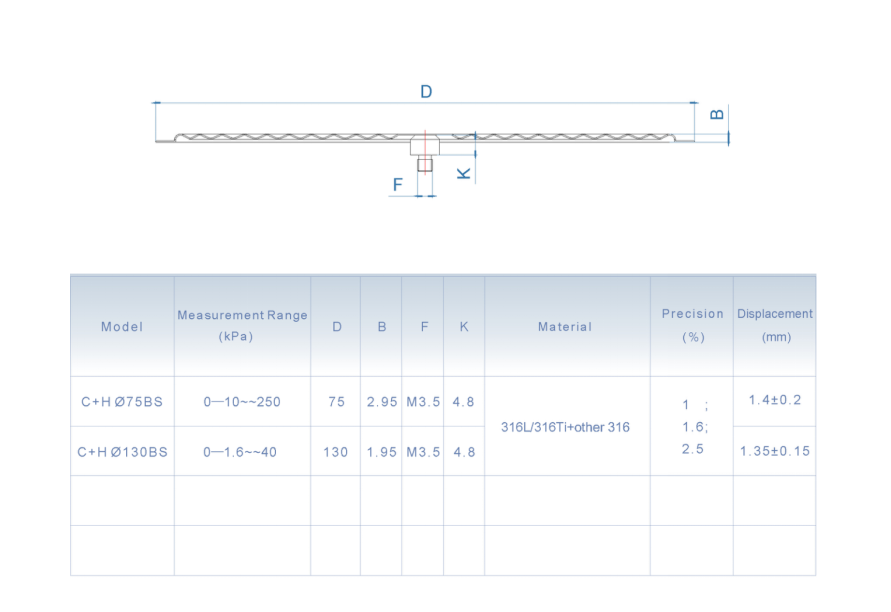

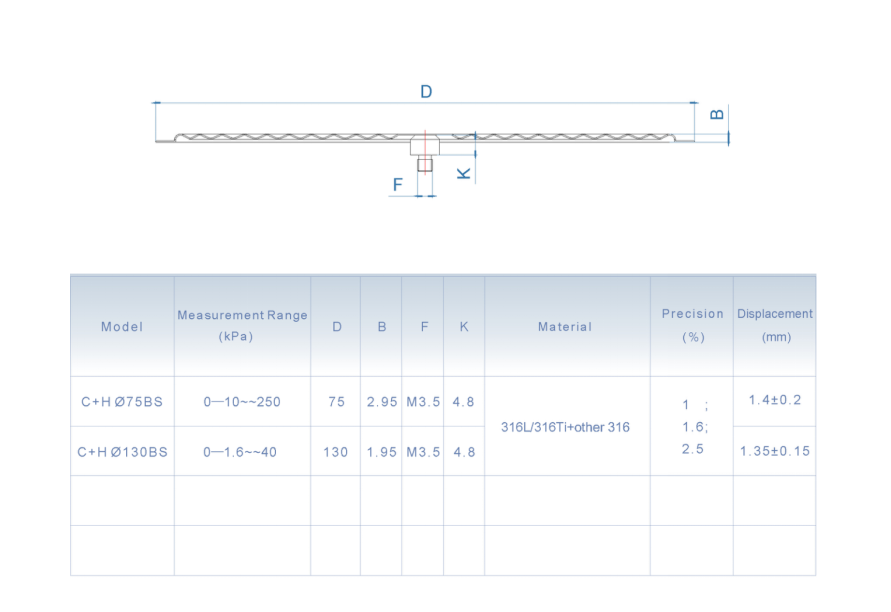

Customization of these elements is crucial to cater to specific application requirements. Factors such as material selection, diaphragm thickness, and design geometry are tailored to withstand varying pressure ranges, temperature conditions, and chemical compatibility. For instance, stainless steel might be chosen for its durability and resistance to corrosion in harsh environments, while thin diaphragms are used for high sensitivity in low-pressure applications.

The custom diaphragm pressure element offers several advantages over standard models. Its bespoke design allows for enhanced accuracy, ensuring minimal measurement errors. It also provides better sealing properties, preventing leaks and maintaining system integrity It also provides better sealing properties, preventing leaks and maintaining system integritycustom diaphragm pressure element. Moreover, customization enables engineers to optimize performance in extreme conditions, such as high-temperature processes or applications involving aggressive fluids .

In the pharmaceutical industry, custom diaphragm pressure elements are used in sterile processing systems, where precision and hygiene are paramount. In oil and gas exploration, they aid in monitoring, contributing to safety and efficiency. They also find application in industrial automation, where they help control and regulate processes based on pressure feedback.

Despite their complexity, custom diaphragm pressure elements are built with simplicity in mind. Their compact size and modular design facilitate easy integration into existing systems, minimizing downtime during installation or maintenance. Additionally, regular calibration ensures continued accuracy and longevity.

In conclusion, the custom diaphragm pressure element is not just a piece of equipment but a precision tool that enables precise pressure measurement and control in diverse industrial scenarios. Its customization capabilities make it adaptable to a wide range of applications, ensuring optimal performance and reliability. As technology continues to advance, we can expect further innovation in this field, leading to more efficient and precise pressure sensing solutions.

.

In the pharmaceutical industry, custom diaphragm pressure elements are used in sterile processing systems, where precision and hygiene are paramount. In oil and gas exploration, they aid in monitoring, contributing to safety and efficiency. They also find application in industrial automation, where they help control and regulate processes based on pressure feedback.

Despite their complexity, custom diaphragm pressure elements are built with simplicity in mind. Their compact size and modular design facilitate easy integration into existing systems, minimizing downtime during installation or maintenance. Additionally, regular calibration ensures continued accuracy and longevity.

In conclusion, the custom diaphragm pressure element is not just a piece of equipment but a precision tool that enables precise pressure measurement and control in diverse industrial scenarios. Its customization capabilities make it adaptable to a wide range of applications, ensuring optimal performance and reliability. As technology continues to advance, we can expect further innovation in this field, leading to more efficient and precise pressure sensing solutions.

.

In the pharmaceutical industry, custom diaphragm pressure elements are used in sterile processing systems, where precision and hygiene are paramount. In oil and gas exploration, they aid in monitoring, contributing to safety and efficiency. They also find application in industrial automation, where they help control and regulate processes based on pressure feedback.

Despite their complexity, custom diaphragm pressure elements are built with simplicity in mind. Their compact size and modular design facilitate easy integration into existing systems, minimizing downtime during installation or maintenance. Additionally, regular calibration ensures continued accuracy and longevity.

In conclusion, the custom diaphragm pressure element is not just a piece of equipment but a precision tool that enables precise pressure measurement and control in diverse industrial scenarios. Its customization capabilities make it adaptable to a wide range of applications, ensuring optimal performance and reliability. As technology continues to advance, we can expect further innovation in this field, leading to more efficient and precise pressure sensing solutions.

.

In the pharmaceutical industry, custom diaphragm pressure elements are used in sterile processing systems, where precision and hygiene are paramount. In oil and gas exploration, they aid in monitoring, contributing to safety and efficiency. They also find application in industrial automation, where they help control and regulate processes based on pressure feedback.

Despite their complexity, custom diaphragm pressure elements are built with simplicity in mind. Their compact size and modular design facilitate easy integration into existing systems, minimizing downtime during installation or maintenance. Additionally, regular calibration ensures continued accuracy and longevity.

In conclusion, the custom diaphragm pressure element is not just a piece of equipment but a precision tool that enables precise pressure measurement and control in diverse industrial scenarios. Its customization capabilities make it adaptable to a wide range of applications, ensuring optimal performance and reliability. As technology continues to advance, we can expect further innovation in this field, leading to more efficient and precise pressure sensing solutions. Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025