Sep . 12, 2024 01:06 Back to list

Diaphragm Contact Pressure Gauge - Precision Measurement Solutions

Understanding Diaphragm Contact Pressure Gauge Technology

In the field of industrial measurement, accuracy and reliability are paramount. One of the essential tools for measuring pressure in various applications is the diaphragm contact pressure gauge. This specialized instrument is designed to provide precise measurements of pressure, especially in environments where mechanical gauges may fall short. In this article, we will explore the technology behind diaphragm contact pressure gauges and their significance in various industries.

What is a Diaphragm Contact Pressure Gauge?

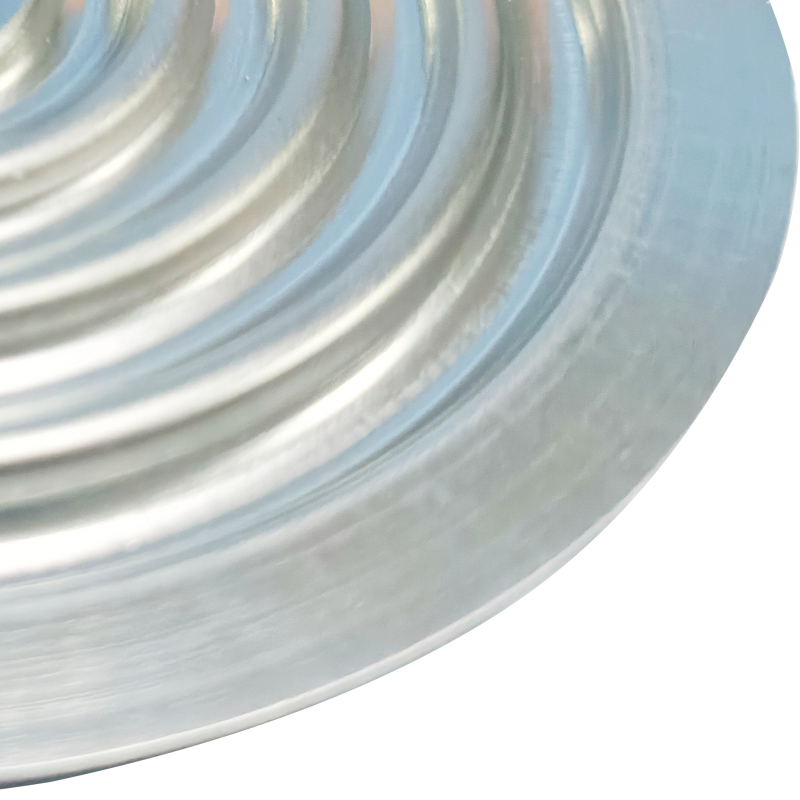

A diaphragm contact pressure gauge is an advanced instrument that employs a flexible diaphragm to sense changes in pressure. When pressure is applied to the diaphragm, it deforms, causing a mechanical movement that is translated into a readable output. Unlike traditional pressure gauges that rely on fluid-filled chambers, diaphragm gauges are highly sensitive and can measure both low and high-pressure scenarios effectively.

The construction of these gauges typically includes a metallic diaphragm, a contact mechanism, and a display unit. The diaphragm is often made from durable materials like stainless steel or other alloys to withstand corrosion and high temperatures, making these gauges suitable for demanding environments.

Applications of Diaphragm Contact Pressure Gauges

Diaphragm contact pressure gauges are used across numerous industries, including

1. Oil and Gas In the exploration and extraction of oil and gas, monitoring pressure is crucial for both safety and efficiency. Diaphragm gauges can measure the pressure in pipes and tanks, ensuring that operations remain within safe limits.

2. Chemical Processing The chemical industry involves various processes that require precise pressure control. Diaphragm gauges are often utilized to monitor reaction vessels and storage tanks, helping to prevent overpressure and potential hazardous situations.

diaphragm contact pressure gauge company

3. Pharmaceuticals In pharmaceutical manufacturing, maintaining specific pressure levels is critical for ensuring product quality. Diaphragm contact pressure gauges assist in the regulation of various processes, from mixing to filtration.

4. HVAC Systems In heating, ventilation, and air conditioning systems, these gauges can measure duct pressure, ensuring optimal performance and energy efficiency in climate control.

Advantages of Diaphragm Contact Pressure Gauges

The use of diaphragm contact pressure gauges offers several advantages

- High Sensitivity They can detect minute changes in pressure, allowing for detailed monitoring and analysis. - Durability Constructed from robust materials, these gauges can endure harsh conditions, providing long-term reliability.

- Versatility Diaphragm gauges can be designed for a wide range of applications, making them suitable for diverse industries.

- Reduced Maintenance With fewer moving parts and a durable design, diaphragm contact pressure gauges often require less maintenance compared to traditional gauges.

Conclusion

Diaphragm contact pressure gauges are an essential component in the toolkit of industries that require precise pressure measurements. Their robust design, high sensitivity, and versatility make them invaluable in ensuring safety and efficiency across various applications. As technology continues to advance, these gauges will likely evolve, further enhancing their accuracy and reliability in critical industrial processes.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025