Sep . 25, 2024 19:10 Back to list

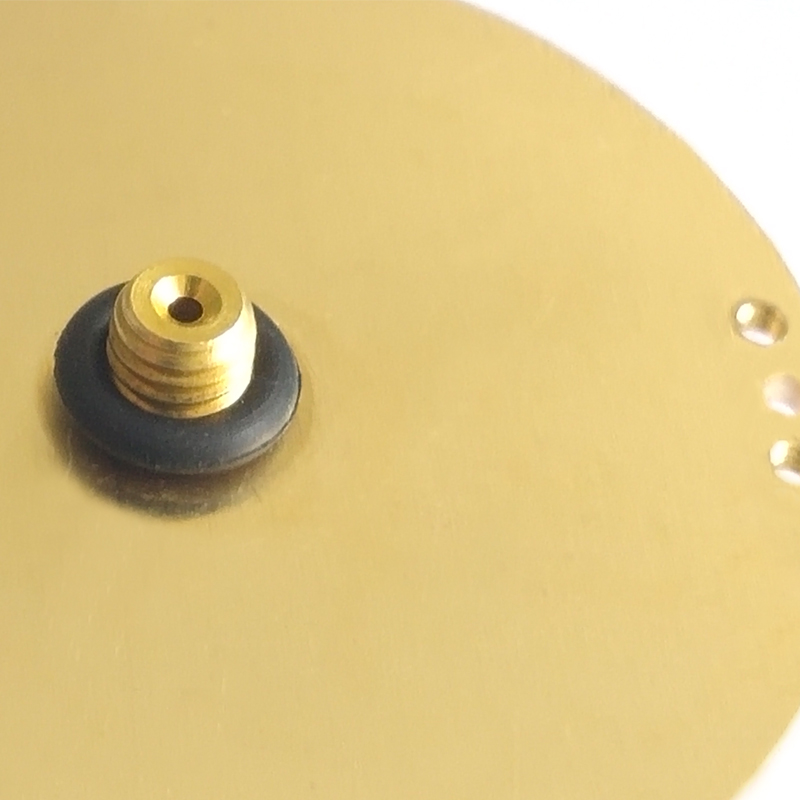

famous photohelic differential pressure gauge

Understanding the Famous Photohelic Differential Pressure Gauge

The Photohelic differential pressure gauge has earned its reputation as one of the most effective tools for monitoring and measuring pressure differences in various applications. With roots in the expanding field of automation and control technology, this instrument is particularly celebrated for its accuracy and reliability. In this article, we will explore the principle of operation, applications, advantages, and some considerations when using the Photohelic gauge.

Principle of Operation

The Photohelic gauge utilizes a differential pressure sensing mechanism to measure the pressure difference between two points. At its core, the device employs a diaphragm that flexes in response to differential pressures, which is then translated into a readable output. The unique feature of the Photohelic gauge is its ability to provide both visual and electronic outputs simultaneously.

One of the most notable aspects of this gauge is its analog-display capabilities. The dial face is calibrated with a scale that allows for quick visual interpretation of pressure differentials, supplemented by a digital readout that offers enhanced precision. The combination of analog and digital displays facilitates immediate response and ease of use—critical factors for operators in various settings.

Applications

The versatility of the Photohelic gauge makes it suitable for a wide range of applications across different industries. Primarily, it is used in HVAC systems for monitoring filter pressure drop, ensuring that central heating and cooling systems operate efficiently. By keeping track of pressure differentials across filters, the Photohelic gauge aids in determining when filters need cleaning or replacement, optimizing energy use and comfort for building occupants.

Another significant application is in pharmaceuticals and cleanroom environments, where maintaining specific pressure conditions is vital to ensure product integrity and safety. The Photohelic gauge can effectively monitor the pressures in these environments, preventing contamination and ensuring compliance with stringent industry standards.

In industrial processes, the gauge is frequently employed to monitor airflow in ducts, ensuring that systems like pneumatic conveying operate correctly. Monitoring differential pressure helps prevent possible system failures and enhances operational efficiency, translating to cost savings for manufacturers.

Advantages

There are several advantages to using the Photohelic differential pressure gauge

famous photohelic differential pressure gauge

1. Accuracy This gauge is renowned for its precision, making it an ideal choice for critical applications where even slight deviations in pressure can have significant implications.

2. Dual Output The ability to provide both analog and digital readings allows for greater flexibility and user-friendliness, particularly in fast-paced environments.

3. Durability Many models of the Photohelic gauge are designed to withstand harsh environmental conditions, extending their usability and reducing maintenance costs.

4. Ease of Installation With straightforward setup requirements, many users appreciate the minimal training necessary to begin using the gauge effectively.

5. Cost-Effective By providing real-time monitoring and alerts regarding pressure changes, industries can avoid costly downtimes or repairs by addressing issues promptly.

Considerations for Use

While the Photohelic gauge boasts an extensive range of advantages, there are certain considerations that users should keep in mind. Proper calibration is essential to ensure ongoing accuracy, particularly after significant changes in system configurations or after extended use. Regular maintenance checks are recommended to extend the lifespan of the instrument and maintain its reliability.

Users should also assess their specific application requirements, as different models of the Photohelic gauge may have varying capabilities in terms of measurement range, materials used in construction, and maximum allowable pressure conditions.

Conclusion

The Photohelic differential pressure gauge stands out as a remarkable instrument within the realm of pressure measurement. Its ability to deliver accurate, reliable readings in a wide array of applications marks it as an indispensable tool across many industries. Whether in HVAC, pharmaceuticals, or general industrial processes, its advantages of precision, dual output, durability, and cost-effectiveness make it a preferred choice for professionals seeking to enhance their operational efficiency. Emphasizing the importance of routine maintenance and calibration will further ensure that the Photohelic gauge continues to serve its vital role in workplace safety and productivity.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025