Nov . 15, 2024 02:29 Back to list

flange diaphragm seal pressure gauge product

Understanding Flange Diaphragm Seal Pressure Gauges A Comprehensive Overview

In industrial contexts, precise measurement and control of pressure are critical for maintaining optimal operating conditions and ensuring the safety and efficiency of various processes. One essential device utilized in achieving this is the flange diaphragm seal pressure gauge. This article delves into the functionality, components, and applications of this vital instrument, providing insight into its significance in modern industrial applications.

What is a Flange Diaphragm Seal Pressure Gauge?

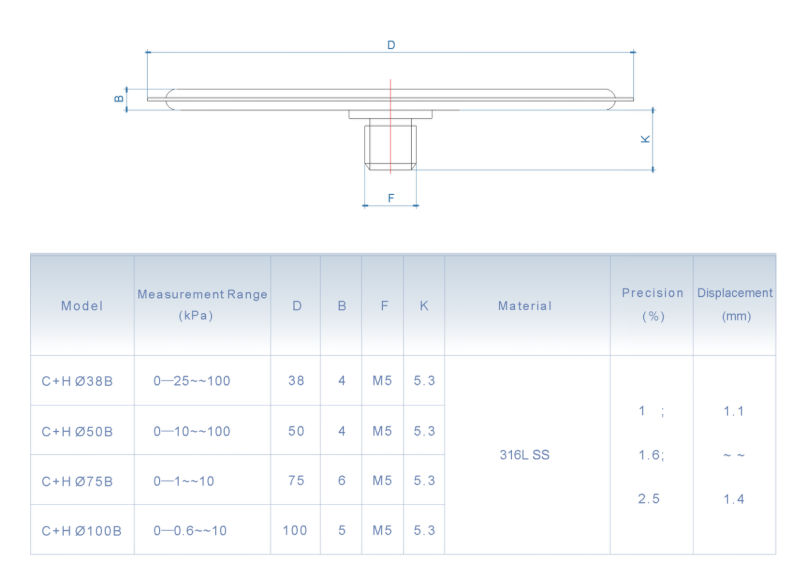

A flange diaphragm seal pressure gauge is a specialized instrument designed to measure the pressure of fluids or gases in a system. Its unique design incorporates a diaphragm seal that isolates the pressure sensing element from the direct impact of the process media. This setup is essential when dealing with corrosive, viscous, or high-temperature fluids that could damage conventional pressure gauges.

Key Components

1. Diaphragm The diaphragm is a flexible membrane that responds to changes in pressure. As pressure increases, the diaphragm deflects, transmitting the pressure change to the gauge's internal mechanism. 2. Seal Housing The seal housing encases the diaphragm, preventing the process fluid from coming into contact with the sensing element of the gauge. This housing is typically made from durable materials, such as stainless steel or other corrosion-resistant alloys, to withstand harsh environments.

3. Flange Connections Flange diaphragm seal gauges feature flange connections that allow for easy installation in piping systems. These flanges ensure a secure and leak-free connection to the process line, facilitating straightforward assembly and maintenance.

4. Sensing Element The sensing element inside the gauge converts the diaphragm movement into a readable pressure measurement. This can be achieved through various mechanisms, including mechanical linkages or electronic transducers.

How it Works

When the pressure of the process medium increases, it exerts force on the diaphragm. This force causes the diaphragm to bend, which in turn moves the connected sensing element. The diaphragm's movement is translated into a corresponding pressure reading, which is displayed on the gauge face. This real-time monitoring is essential for maintaining safe operational conditions and achieving accurate process control.

Applications of Flange Diaphragm Seal Pressure Gauges

Flange diaphragm seal pressure gauges are incredibly versatile and find applications across various industries, including

flange diaphragm seal pressure gauge product

1. Chemical Processing In chemical plants, corrosive substances are often present. Diaphragm seals protect the gauge from contact with these substances and ensure accurate pressure readings.

2. Food and Beverage High hygiene standards are vital in food processing. These gauges help maintain the integrity of the production process without contaminating the food products.

3. Pharmaceutical Similar to the food industry, pharmaceutical applications require stringent cleanliness and precision. Diaphragm seal gauges are critical in monitoring the pressure of various fluids in sterile environments.

4. Oil and Gas In this sector, measurements of high pressure and temperature are routine. Flange diaphragm seals contribute to safety and performance by providing reliable pressure readings.

5. Water Treatment In municipal and industrial water treatment facilities, these gauges monitor pressure throughout the treatment process, ensuring safe and efficient operation.

Benefits of Using Flange Diaphragm Seal Pressure Gauges

- Protection Against Corrosion The isolating diaphragm protects the gauge from corrosive fluids, extending the life of the instrument. - Accurate Readings The device provides accurate and real-time pressure readings vital for maintaining system integrity.

- Versatility Suitable for a wide range of industrial applications, from food processing to oil exploration.

- Easy Installation The flange design allows for straightforward integration into existing systems.

Conclusion

Flange diaphragm seal pressure gauges are indispensable tools in an array of industries requiring precise and reliable pressure measurements. Their robust design not only enhances the safety and efficiency of various processes but also extends the lifespan of the equipment. Understanding the function and application of these gauges is crucial for any industrial operation aiming for excellence in process management and safety standards. As technology advances, the importance of such innovative solutions in critical applications will only continue to grow, solidifying the flange diaphragm seal pressure gauge's place as a cornerstone in industrial instrumentation.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025