Dez . 12, 2024 21:15 Back to list

high pressure differential pressure gauge factory

High Pressure Differential Pressure Gauge An Essential Tool for Industrial Applications

In industrial settings, precision and reliability are paramount. One critical instrument that ensures optimal performance in fluid dynamics, process control, and system monitoring is the high-pressure differential pressure gauge. This specialized gauge serves as a vital tool in various sectors, including oil and gas, chemical processing, HVAC, and water treatment. In this article, we will explore the significance, functionality, and factory considerations of high-pressure differential pressure gauges.

Understanding Differential Pressure

Differential pressure refers to the difference in pressure between two points in a system. This measurement is crucial in many applications, such as monitoring filters, flow meters, and pumps. By understanding the differential pressure, operators can determine if equipment is performing efficiently or if maintenance is required. High-pressure differential pressure gauges are specifically designed to measure these differences in situations where the pressure levels can vary significantly, often exceeding 500 psi.

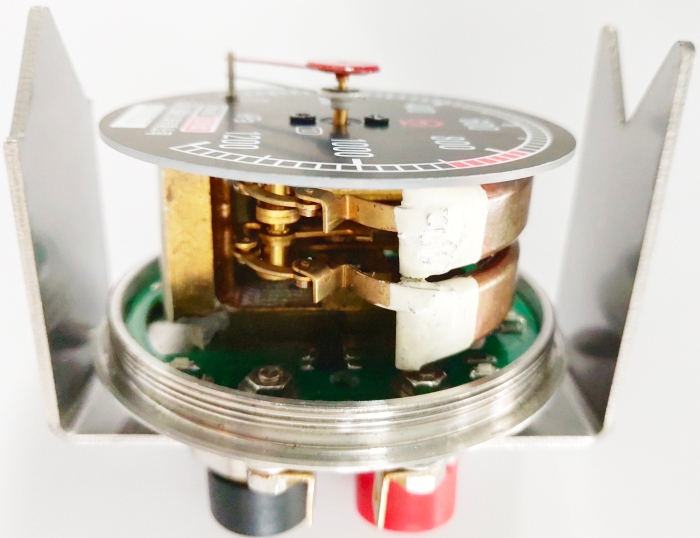

Construction and Functionality

High-pressure differential pressure gauges typically comprise a Bourdon tube, diaphragm, or piezoresistive sensors, depending on the application's requirements. The gauge measures pressure in two different areas; the difference is displayed on a calibrated dial or digital screen. The construction materials are chosen based on the expected environmental conditions and the fluids being monitored to ensure durability and resistance to corrosion.

These gauges are designed to operate effectively in high-pressure environments, with features that allow them to withstand extreme temperatures and corrosive substances

. Manufacturers often offer a range of models with various pressure ratings, allowing users to select the gauge that best suits their application.Importance in Industrial Applications

high pressure differential pressure gauge factory

The importance of high-pressure differential pressure gauges cannot be overstated. In oil and gas extraction, for example, they are used to monitor the pressure differential across filters and separators, ensuring that the extraction process remains efficient and safe. In chemical processing, they help maintain the correct pressure levels throughout the production process, preventing equipment failure and hazardous situations.

In HVAC systems, these gauges enable the monitoring of air and water flow, contributing to energy efficiency and comfort. In water treatment facilities, maintaining proper pressure differentials is crucial for effective filtration and purification processes. Overall, these instruments play a pivotal role in enhancing operational efficiency, safety, and reliability across various industries.

Factory Considerations

When selecting a high-pressure differential pressure gauge, it is crucial to consider the manufacturing standards of the factory producing them. A reputable gauge manufacturer will adhere to industry standards such as the ISO 9001 certification, indicating a commitment to quality management and continuous improvement.

Additionally, the factory should employ advanced manufacturing techniques and quality assurance testing to ensure that each gauge meets its specified accuracy and durability. The availability of customization options, such as different materials, pressure ranges, and size specifications, can also play a significant role in meeting the unique needs of specific industries.

Furthermore, excellent customer support and service are essential, as they help clients choose the right product and assist in maintenance and calibration when necessary.

Conclusion

High-pressure differential pressure gauges are indispensable tools that provide critical data for various industrial processes. Their reliable performance across different applications ensures efficiency and safety in operations. By choosing a high-quality gauge from a reputable factory, industries can optimize their workflows and minimize potential risks, making these gauges an integral part of modern engineering and process management.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025