Dez . 17, 2024 10:06 Back to list

jah diaphragm and capsule pressure gauges

Understanding Jah Diaphragm and Capsule Pressure Gauges

Pressure gauges are critical components in various industrial applications, enabling accurate monitoring and regulation of pressure in systems ranging from HVAC to process engineering. Among the different types of pressure measuring instruments, diaphragm and capsule pressure gauges, notably those produced by Jah, have become popular due to their reliability and precision. This article delves into the features and applications of Jah diaphragm and capsule pressure gauges, highlighting their significance in pressure measurement.

What are Diaphragm and Capsule Pressure Gauges?

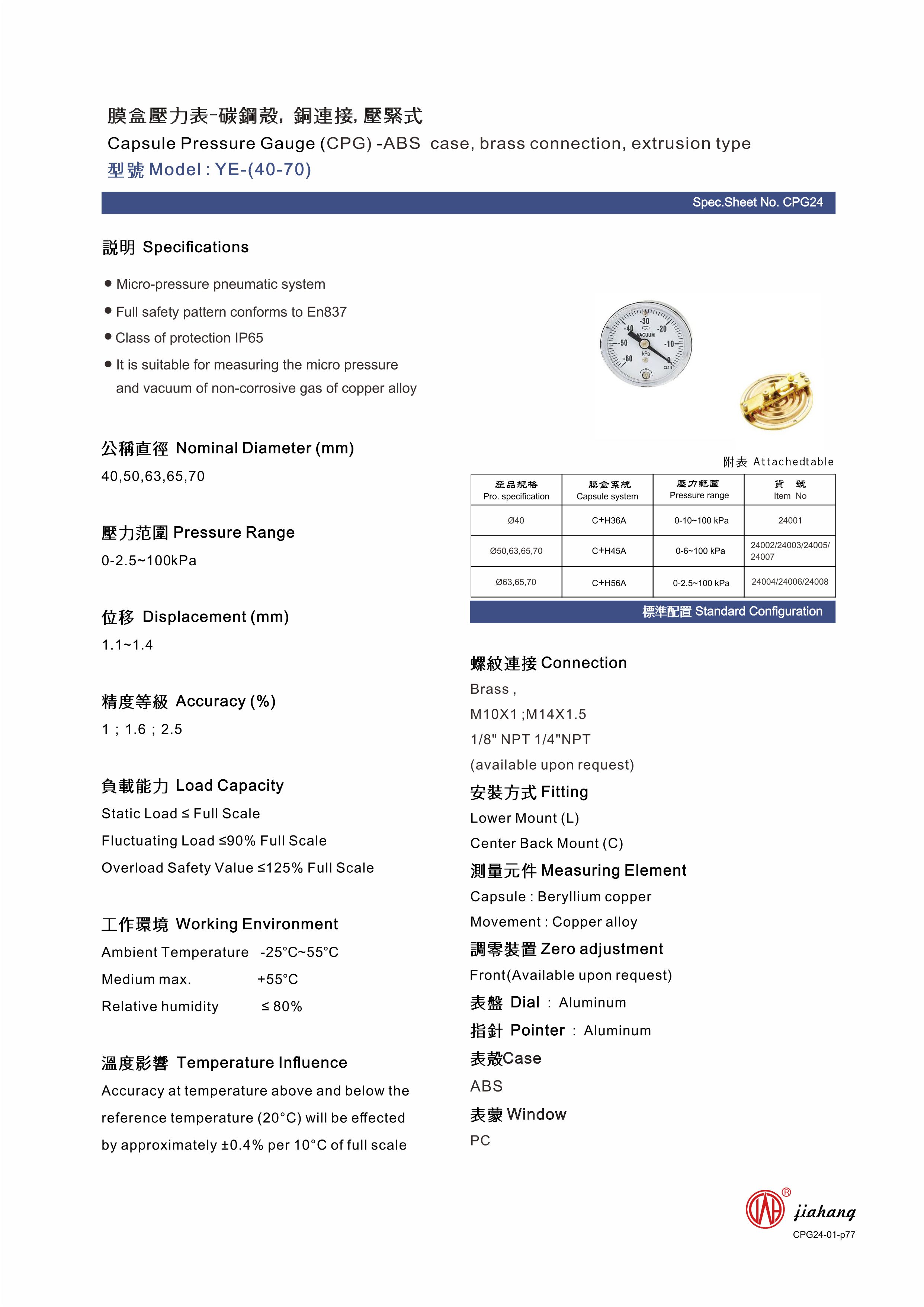

Diaphragm pressure gauges utilize a flexible diaphragm that deflects in response to pressure changes within a system. This deflection is then translated into an indicator motion that displays the pressure reading, often calibrated in various units (such as psi, bar, or kPa). They are particularly adept at measuring low to medium pressures and are often used in applications where vibrations or shocks may present challenges for other instruments.

Capsule pressure gauges, on the other hand, employ an elastic capsule that expands or contracts based on the pressure applied. The movement of the capsule drives a pointer on a dial, providing a visual representation of the pressure level. Capsule gauges are particularly suited for measuring very low pressures in gases and liquids, making them indispensable in many scientific and industrial settings.

Advantages of Jah Diaphragm and Capsule Gauges

One notable advantage of Jah diaphragm and capsule gauges is their durability. Equipped with materials that can withstand aggressive environments, these gauges can operate effectively in a range of temperatures and conditions without compromising accuracy. The high-quality construction of Jah products means they are reliable under fluctuating pressures and are less prone to failure over time compared to other brands.

jah diaphragm and capsule pressure gauges

Another significant benefit is their accuracy and sensitivity. The sensitive diaphragm and capsule designs allow for precise measurement of pressure fluctuations, which is essential in applications ranging from lab experiments to industrial processes that require meticulous pressure control. By delivering consistent readings, Jah pressure gauges help engineers and technicians maintain system integrity and optimize performance.

Applications of Jah Diaphragm and Capsule Gauges

Jah diaphragm and capsule pressure gauges find applications across various industries. In the food and beverage sector, these gauges help monitor processes that demand strict hygiene protocols and accurate pressure readings, ensuring product safety and quality. In pharmaceuticals, they are crucial for maintaining the integrity of systems involved in drug formulation and distribution.

In HVAC applications, Jah gauges are used to monitor duct pressure, ensuring efficient airflow and energy use. Moreover, in the oil and gas industry, these pressure gauges assist in monitoring pressure levels in pipelines and storage tanks, helping prevent leaks and maintaining safety standards.

Conclusion

Jah diaphragm and capsule pressure gauges are invaluable tools in any situation that demands precise pressure measurement. Their robust design, accuracy, and adaptability make them suitable for various sectors, from industrial applications to health and safety processes. The continued evolution of pressure measurement technology points towards an even greater role for products like those from Jah, ensuring that engineers and technicians have reliable instruments to maintain system integrity and enhance operational efficiency.

For professionals looking for a dependable solution to pressure measurement, investing in Jah diaphragm and capsule pressure gauges is a wise choice. With their proven track record of performance and reliability, these gauges help ensure that systems remain efficient, safe, and compliant with industry standards. Whether for industrial, scientific, or commercial applications, the importance of accurate pressure measurement cannot be overstated, making Jah gauges a trusted ally in achieving operational success.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025