Jan . 30, 2025 04:02 Back to list

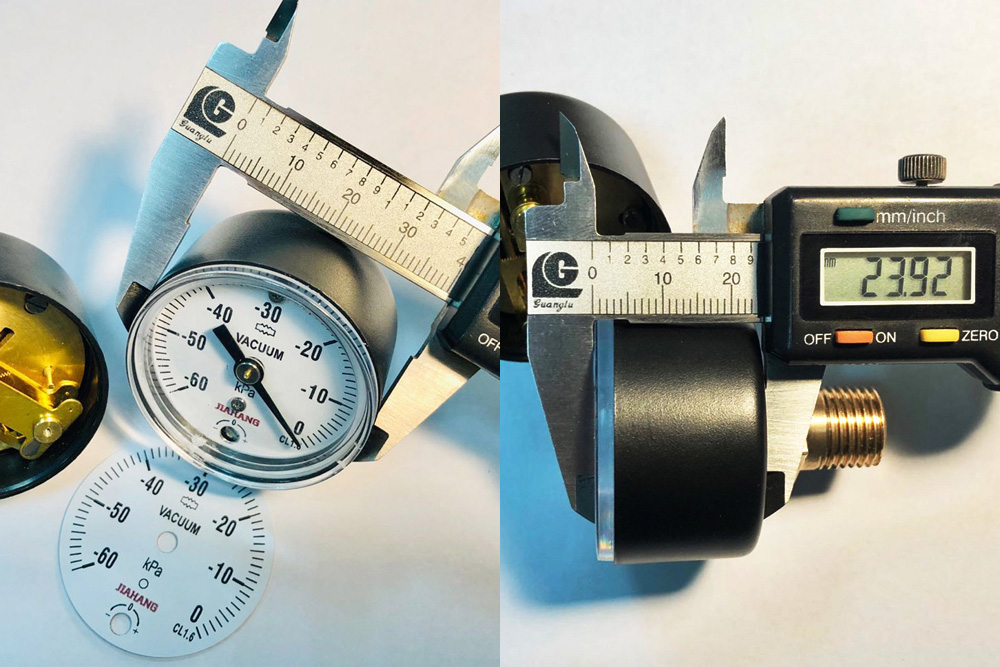

diaphragm capsule pressure gauge,

Understanding pressure gauge technologies is crucial for industries that value precision, reliability, and durability in measurement tools. The OEM diaphragm capsule pressure gauge is a sophisticated piece of equipment that caters to these needs, standing out in sectors such as pharmaceuticals, petrochemicals, and food processing. This article delves into the essential features, functionalities, and advantages of these pressure gauges, providing a comprehensive guide for industry professionals and manufacturers alike.

In terms of authoritativeness, the OEM diaphragm capsule pressure gauge is backed by extensive research and development, adhering to international standards and protocols. Manufacturers who produce these gauges are typically equipped with years of industry experience, contributing to a robust product capable of meeting rigorous demands. By adhering to ISO certification standards and ensuring precision engineering, these gauges provide quality assurance and reliability—factors that bolster their authoritative presence in competitive industrial landscapes. Trustworthiness is intrinsic to the OEM diaphragm capsule pressure gauge, as it consistently delivers accurate and reliable pressure measurements. The instrument’s design ensures a minimal margin of error, a critical aspect for industries where precise pressure monitoring is paramount. Additionally, the longevity of the device translates to cost-effectiveness over time, making it a sound investment for any industry reliant on high-quality measurement tools. Regular maintenance and calibration further enhance its reliability, ensuring that it operates within the specified parameters without deviation. In conclusion, the OEM diaphragm capsule pressure gauge is an essential asset for any industry that values precision, durability, and adaptability in pressure measurement. By providing a buffer between the medium and the measurement instrument, these gauges protect against contamination and damage while ensuring consistent performance. With customizable options, rigorous standards, and extensive manufacturer expertise, these gauges are positioned as reliable components in any technical setup. Industries stand to gain significantly by leveraging the technological advantages offered by these sophisticated pressure gauges, making them a staple in precision-driven operations across the globe.

In terms of authoritativeness, the OEM diaphragm capsule pressure gauge is backed by extensive research and development, adhering to international standards and protocols. Manufacturers who produce these gauges are typically equipped with years of industry experience, contributing to a robust product capable of meeting rigorous demands. By adhering to ISO certification standards and ensuring precision engineering, these gauges provide quality assurance and reliability—factors that bolster their authoritative presence in competitive industrial landscapes. Trustworthiness is intrinsic to the OEM diaphragm capsule pressure gauge, as it consistently delivers accurate and reliable pressure measurements. The instrument’s design ensures a minimal margin of error, a critical aspect for industries where precise pressure monitoring is paramount. Additionally, the longevity of the device translates to cost-effectiveness over time, making it a sound investment for any industry reliant on high-quality measurement tools. Regular maintenance and calibration further enhance its reliability, ensuring that it operates within the specified parameters without deviation. In conclusion, the OEM diaphragm capsule pressure gauge is an essential asset for any industry that values precision, durability, and adaptability in pressure measurement. By providing a buffer between the medium and the measurement instrument, these gauges protect against contamination and damage while ensuring consistent performance. With customizable options, rigorous standards, and extensive manufacturer expertise, these gauges are positioned as reliable components in any technical setup. Industries stand to gain significantly by leveraging the technological advantages offered by these sophisticated pressure gauges, making them a staple in precision-driven operations across the globe.

Share

Latest news

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025