Jun . 13, 2024 11:02 Back to list

Wika diaphragm pressure gauge manufacturers

Understanding WiKA Diaphragm Type Pressure Gauges A Deep Dive into Manufacturing Excellence

WiKA, a globally recognized leader in the field of measurement technology, is renowned for its exceptional craftsmanship in manufacturing diaphragm type pressure gauges. These precision instruments are an essential component in various industries where accurate pressure monitoring is vital, including chemical, petrochemical, pharmaceutical, and food processing sectors.

A diaphragm type pressure gauge from WiKA is designed to provide high accuracy and reliability under demanding conditions. The unique feature of these gauges lies in their diaphragm element, which acts as a flexible barrier between the process fluid and the measuring mechanism. This design not only ensures protection against aggressive media but also enhances sensitivity, making it ideal for low-pressure measurements.

WiKA's manufacturing facilities are equipped with state-of-the-art technology and adhere to strict quality standards. Each stage of production, from material selection to final assembly, undergoes rigorous testing and inspection to ensure that every gauge meets the highest level of performance and durability. The company's commitment to innovation is evident in the use of advanced materials, such as stainless steel and exotic alloys, which enhance the gauge's resistance to corrosion and temperature fluctuations.

The diaphragm itself is meticulously crafted to withstand extreme pressures while maintaining its integrity. The welding process, a critical step in the manufacture of these gauges, is executed with precision to ensure a leak-proof seal. WiKA's skilled technicians employ both traditional and automated welding techniques, ensuring consistency and quality in every unit produced WiKA's skilled technicians employ both traditional and automated welding techniques, ensuring consistency and quality in every unit produced WiKA's skilled technicians employ both traditional and automated welding techniques, ensuring consistency and quality in every unit produced WiKA's skilled technicians employ both traditional and automated welding techniques, ensuring consistency and quality in every unit produced

WiKA's skilled technicians employ both traditional and automated welding techniques, ensuring consistency and quality in every unit produced WiKA's skilled technicians employ both traditional and automated welding techniques, ensuring consistency and quality in every unit produced wika diaphragm type pressure gauge factories.

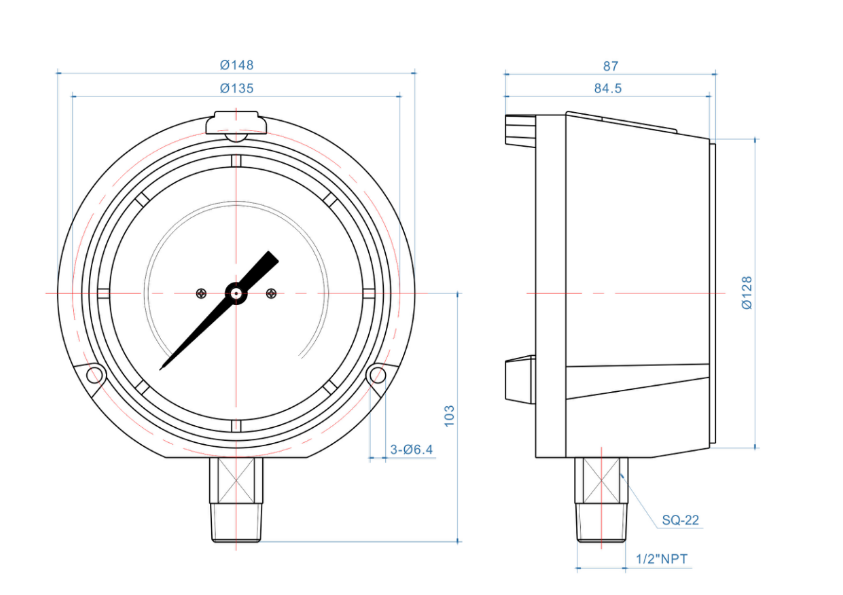

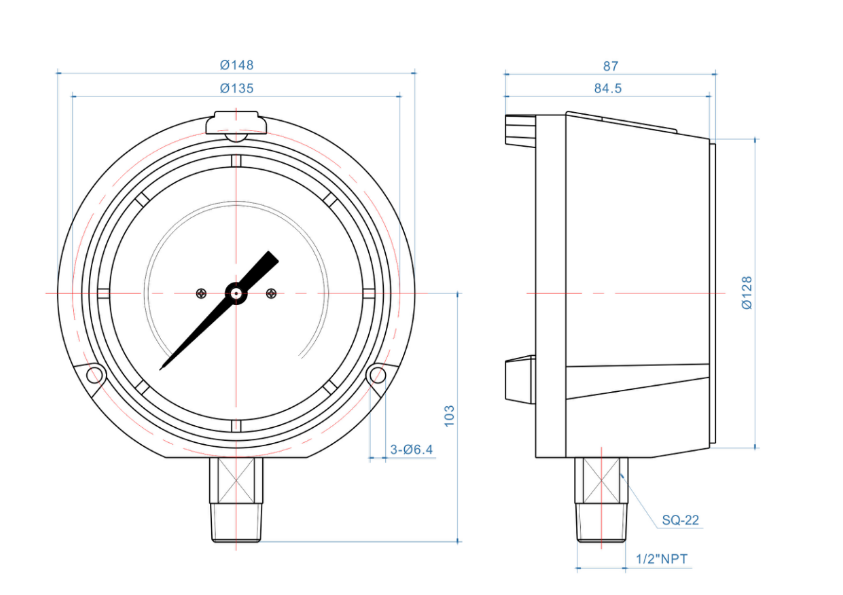

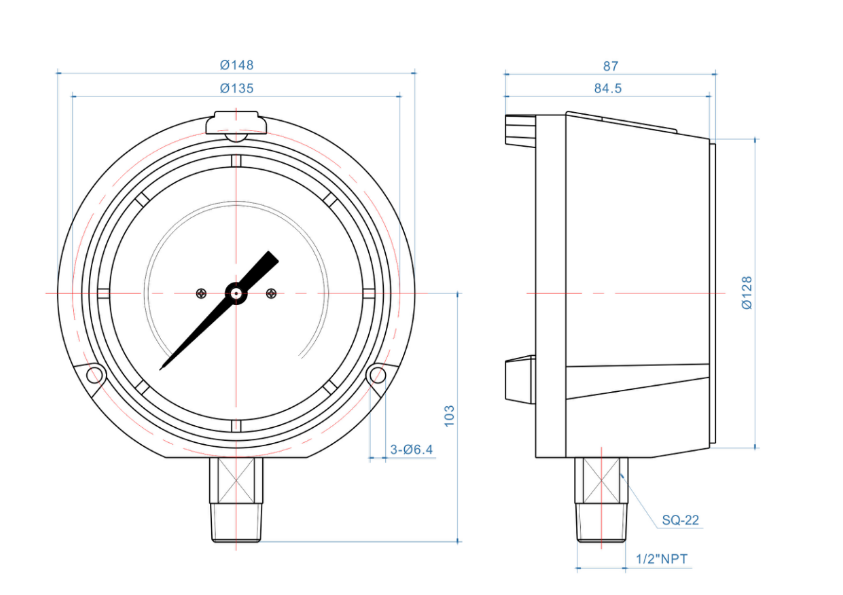

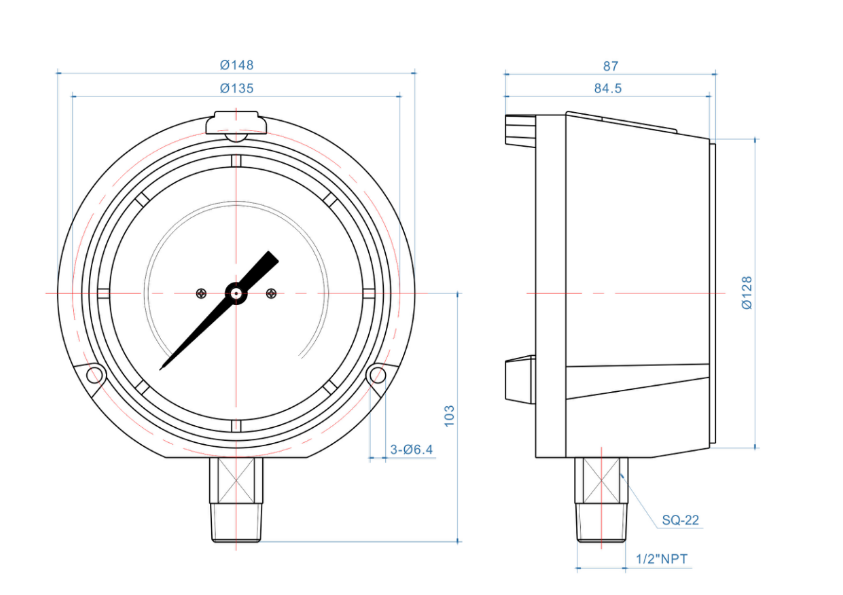

Moreover, WiKA offers customization options to cater to specific customer requirements. From different pressure ranges and connection types to various dial sizes and display options, their diaphragm type pressure gauges can be tailored to suit diverse industrial applications. This flexibility, coupled with their robust construction, makes WiKA's products a preferred choice for engineers worldwide.

In addition to manufacturing, WiKA provides comprehensive services including calibration, repair, and maintenance, further solidifying their position as a one-stop solution provider in the industry. Their global network of service centers ensures prompt and efficient support, minimizing downtime for customers.

In conclusion, WiKA's diaphragm type pressure gauges embody the fusion of engineering excellence and manufacturing prowess. With a focus on precision, durability, and customer-centric solutions, WiKA continues to set benchmarks in the pressure measurement industry. Their unwavering commitment to quality and innovation ensures that their diaphragm type pressure gauges remain at the forefront of reliable and efficient pressure monitoring solutions.

wika diaphragm type pressure gauge factories.

Moreover, WiKA offers customization options to cater to specific customer requirements. From different pressure ranges and connection types to various dial sizes and display options, their diaphragm type pressure gauges can be tailored to suit diverse industrial applications. This flexibility, coupled with their robust construction, makes WiKA's products a preferred choice for engineers worldwide.

In addition to manufacturing, WiKA provides comprehensive services including calibration, repair, and maintenance, further solidifying their position as a one-stop solution provider in the industry. Their global network of service centers ensures prompt and efficient support, minimizing downtime for customers.

In conclusion, WiKA's diaphragm type pressure gauges embody the fusion of engineering excellence and manufacturing prowess. With a focus on precision, durability, and customer-centric solutions, WiKA continues to set benchmarks in the pressure measurement industry. Their unwavering commitment to quality and innovation ensures that their diaphragm type pressure gauges remain at the forefront of reliable and efficient pressure monitoring solutions.

WiKA's skilled technicians employ both traditional and automated welding techniques, ensuring consistency and quality in every unit produced WiKA's skilled technicians employ both traditional and automated welding techniques, ensuring consistency and quality in every unit produced

WiKA's skilled technicians employ both traditional and automated welding techniques, ensuring consistency and quality in every unit produced WiKA's skilled technicians employ both traditional and automated welding techniques, ensuring consistency and quality in every unit produced wika diaphragm type pressure gauge factories.

Moreover, WiKA offers customization options to cater to specific customer requirements. From different pressure ranges and connection types to various dial sizes and display options, their diaphragm type pressure gauges can be tailored to suit diverse industrial applications. This flexibility, coupled with their robust construction, makes WiKA's products a preferred choice for engineers worldwide.

In addition to manufacturing, WiKA provides comprehensive services including calibration, repair, and maintenance, further solidifying their position as a one-stop solution provider in the industry. Their global network of service centers ensures prompt and efficient support, minimizing downtime for customers.

In conclusion, WiKA's diaphragm type pressure gauges embody the fusion of engineering excellence and manufacturing prowess. With a focus on precision, durability, and customer-centric solutions, WiKA continues to set benchmarks in the pressure measurement industry. Their unwavering commitment to quality and innovation ensures that their diaphragm type pressure gauges remain at the forefront of reliable and efficient pressure monitoring solutions.

wika diaphragm type pressure gauge factories.

Moreover, WiKA offers customization options to cater to specific customer requirements. From different pressure ranges and connection types to various dial sizes and display options, their diaphragm type pressure gauges can be tailored to suit diverse industrial applications. This flexibility, coupled with their robust construction, makes WiKA's products a preferred choice for engineers worldwide.

In addition to manufacturing, WiKA provides comprehensive services including calibration, repair, and maintenance, further solidifying their position as a one-stop solution provider in the industry. Their global network of service centers ensures prompt and efficient support, minimizing downtime for customers.

In conclusion, WiKA's diaphragm type pressure gauges embody the fusion of engineering excellence and manufacturing prowess. With a focus on precision, durability, and customer-centric solutions, WiKA continues to set benchmarks in the pressure measurement industry. Their unwavering commitment to quality and innovation ensures that their diaphragm type pressure gauges remain at the forefront of reliable and efficient pressure monitoring solutions. Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025