Okt . 06, 2024 11:29 Back to list

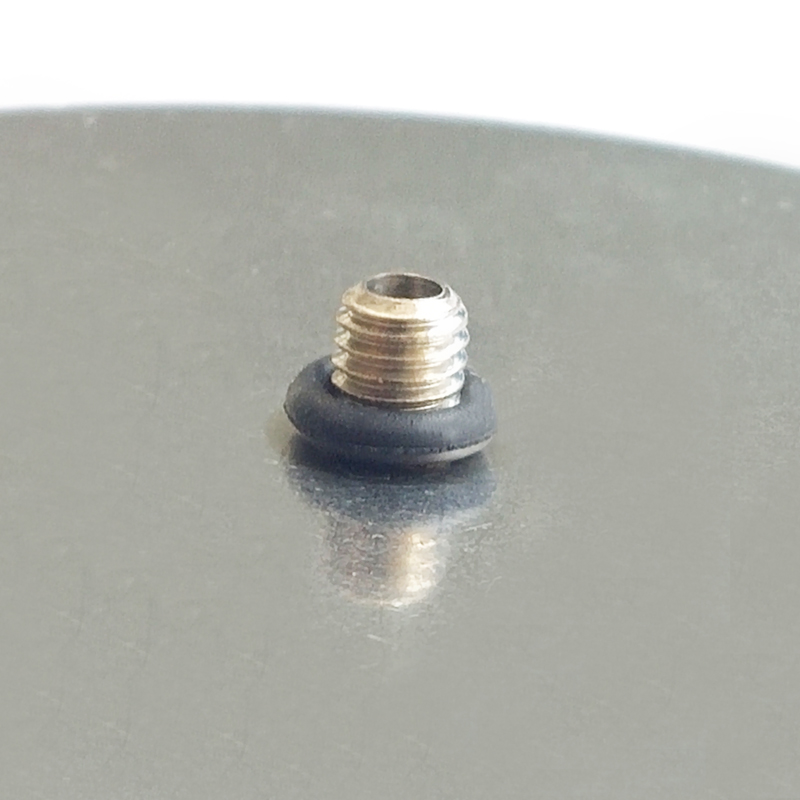

wika diaphragm seal type pressure gauge products

Exploring WIKA Diaphragm Seal Type Pressure Gauges

Pressure measurement is a critical component in various industries, ensuring the safety, efficiency, and reliability of processes involving gases and liquids. One popular solution for this purpose is the diaphragm seal type pressure gauge, particularly those produced by WIKA, a global leader in pressure, temperature, and level measurement technology. In this article, we'll delve into the features, benefits, applications, and considerations surrounding WIKA diaphragm seal type pressure gauges.

What is a Diaphragm Seal Type Pressure Gauge?

A diaphragm seal type pressure gauge is designed to measure the pressure of corrosive, viscous, or high-temperature fluids while protecting the measuring instrument from direct contact with the process media. This is achieved through the use of a flexible diaphragm that separates the pressure gauge internals from the process fluid. The diaphragm transmits the pressure exerted by the fluid to the gauge, allowing for accurate readings without compromising the integrity of the instrumentation.

Key Features of WIKA Diaphragm Seal Type Pressure Gauges

1. Robust Construction WIKA's diaphragm seals are manufactured from high-quality materials such as stainless steel, Monel, or special alloys tailored to withstand harsh environments. This ensures longevity and reliability in a variety of applications.

2. Versatility These pressure gauges are versatile and can be used in a wide range of industries, including chemical, petrochemical, food and beverage, pharmaceutical, and more. They are adaptable to various process conditions and media types.

3. Various Designs WIKA offers an array of diaphragm seals with different designs and sizes, allowing for customization based on specific application requirements. This includes options like flush diaphragm designs for hygienic processes or larger diaphragm areas for high-viscosity fluids.

5. Different Measuring Principles WIKA provides gauges that operate on different measuring principles, including Bourdon tube, capsule, and digital technologies, accommodating diverse customer needs.

Advantages of Using WIKA Diaphragm Seal Type Pressure Gauges

wika diaphragm seal type pressure gauge products

- Protection from Media The primary advantage of using a diaphragm seal is to protect the pressure gauge from corrosive or viscous fluids, thereby extending the life of the instrument and reducing maintenance costs.

- Improved Accuracy The separation of the measuring element from the process media can enhance measurement accuracy, particularly in fluctuating pressure conditions.

- Reduced Fouling By preventing direct contact with the fluid, diaphragm seals significantly reduce the risk of fouling or clogging, a common issue in pressure measurement, especially with viscous or particulate-laden fluids.

- Maintenance-Friendly Many WIKA diaphragm seal systems are designed for easy cleaning and maintenance, making them suitable for sterile or hygienic applications, such as in the food and pharmaceutical industries.

Applications

The applications for WIKA diaphragm seal type pressure gauges are wide-ranging. In the chemical industry, they are crucial for monitoring the pressures in reactors and pipelines handling aggressive chemicals. In food and beverage processing, they help maintain the integrity of sensitive products by preventing contamination. Pharmaceutical applications often require stringent cleanliness; hence, diaphragm seal gauges ensure compliance with hygiene standards. Additionally, these gauges play a significant role in water treatment facilities, oil and gas industries, and HVAC systems.

Considerations

When selecting a diaphragm seal type pressure gauge, it is essential to consider the nature of the process media, including its temperature, viscosity, and corrosiveness. Selecting the appropriate material for the diaphragm seal and gauge is critical to ensure compatibility and performance. Additionally, the installation location, potential for pressure pulsations, and required accuracy level should also be taken into account to optimize the selection.

Conclusion

WIKA diaphragm seal type pressure gauges represent a vital tool in modern industrial applications. Their robust design, versatility, and ability to handle challenging media make them indispensable for ensuring safe and efficient operations. By understanding their features and applications, businesses can make informed decisions to enhance their pressure measurement solutions and contribute to greater process reliability. With WIKA’s commitment to innovation and quality, customers can trust they are receiving top-tier products that can withstand the demands of their specific industries.

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025