Okt . 18, 2024 15:33 Back to list

Manufacturers of Wika Differential Pressure Gauge Model 733 for Accurate Measurements

Understanding WIKA Differential Pressure Gauge 733 Manufacturers, Features, and Applications

The WIKA Differential Pressure Gauge 733 is a high-precision measurement instrument designed for a wide range of industrial applications. As a pivotal tool in many process industries, it measures the difference in pressure between two points in a system. This article delves into the key features, manufacturing standards, and applications of the WIKA 733 model, highlighting why it is a preferred choice among engineers and technicians.

Key Features of WIKA Differential Pressure Gauge 733

1. Accuracy and Reliability One of the foremost attributes of the WIKA 733 differential pressure gauge is its accuracy. It offers precise measurement readings which are essential for maintaining system efficiency and safety. Built with high-quality materials and strict manufacturing processes, these gauges are designed to withstand challenging environments while delivering consistent performance.

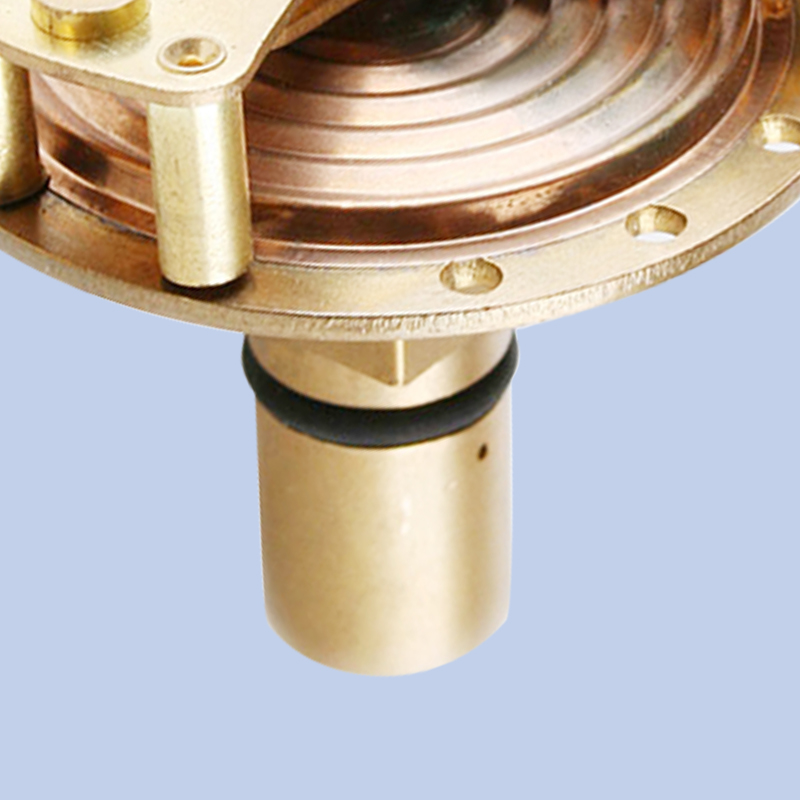

2. Robust Construction The WIKA 733 features a durable design that allows it to operate effectively in harsh conditions. Constructed with stainless steel or brass, it is resistant to corrosion and wear, ensuring longevity in demanding industrial settings.

3. Wide Measuring Range This model supports a variety of measuring ranges, catering to different operational needs. With the capability to measure both high and low-pressure differentials, the WIKA 733 can be utilized across several applications, from HVAC systems to chemical processing.

4. Easy Installation and Maintenance WIKA engineers have designed the differential pressure gauge for straightforward installation. Its user-friendly features facilitate not only the initial setup but also the ongoing maintenance, making it a practical choice for operators and maintenance personnel alike.

5. Versatile Application The range of possible applications is extensive. WIKA 733 can be found in HVAC systems, filtration monitoring, pump performance testing, and process control in various manufacturing industries. This versatility is a significant advantage, making it an ideal addition to any toolkit.

Manufacturing Standards and Quality Assurance

WIKA is renowned globally for its commitment to quality and innovation in pressure measurement technology. The manufacturing of the 733 gauge adheres to rigorous quality standards, including ISO 9001 certification. This commitment to quality assurance ensures that each gauge produced meets the high expectations set forth by international industry standards.

wika differential pressure gauge 733 manufacturers

In addition to ISO certification, WIKA implements stringent testing procedures at every stage of production. From material selection to final inspection, each gauge is subjected to a series of tests to verify its durability and precision. This uncompromising approach to quality control has established WIKA as a trusted name in the field of pressure measurement.

Applications of WIKA Differential Pressure Gauge 733

The versatility of the WIKA 733 makes it suitable for an array of applications across various industries

1. Water and Wastewater Treatment In these settings, the gauge is used to monitor filter status and ensure optimal flow rates, crucial for efficient treatment processes.

2. Oil and Gas The differential pressure gauge performs critical functions in oil and gas applications, such as monitoring system performance and ensuring safe operation within pipelines.

3. Pharmaceutical and Food Industries The need for precise measurement in controlled environments makes the WIKA 733 ideal for these sectors. It helps ensure compliance with regulatory standards by maintaining optimal pressure differentials.

4. Heating, Ventilation, and Air Conditioning (HVAC) In HVAC systems, the gauge measures pressure drops across filters and coils, optimizing energy usage and performance.

5. Industrial Manufacturing It plays a crucial role in ensuring the efficient operation of pumps, compressors, and other equipment, contributing to overall productivity.

Conclusion

The WIKA Differential Pressure Gauge 733 stands out as a premier instrument for accurately measuring pressure differentials in various industries. With its robust construction, high accuracy, and ease of use, it meets the rigorous demands of modern industrial applications. Coupled with WIKA's dedication to quality and innovation, the 733 gauge continues to be a trusted choice for engineers and technicians around the world. As industries evolve and the demand for precision increases, the role of devices like the WIKA 733 will only become more significant, ensuring operational efficiency and safety across all sectors.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025