Δεκ . 05, 2024 08:48 Back to list

Top Cryogenic Differential Pressure Gauges for Precision Measurement in Low-Temperature Applications

The Best Cryogenic Differential Pressure Gauges An Overview

Cryogenic systems are pivotal in various industries, including aerospace, healthcare, and energy, due to their ability to operate at extremely low temperatures. Within these systems, accurate measurement of pressure is crucial for ensuring safety, efficiency, and optimal performance. Among the various tools available, cryogenic differential pressure gauges stand out as vital instruments for monitoring and maintaining the integrity of cryogenic processes. This article explores some of the best cryogenic differential pressure gauges available, highlighting their features, applications, and advantages.

Understanding Differential Pressure Gauges

Differential pressure gauges measure the difference in pressure between two points within a system. In cryogenic applications, these gauges are designed to perform accurately in environments where temperatures can drop below -150°C (-238°F). The essential attributes of a reliable cryogenic differential pressure gauge include high sensitivity, minimal temperature effects, robustness against thermal and mechanical stress, and excellent resistance to environmental factors such as moisture and contaminants.

Key Features to Look For

When selecting a cryogenic differential pressure gauge, several features should be considered

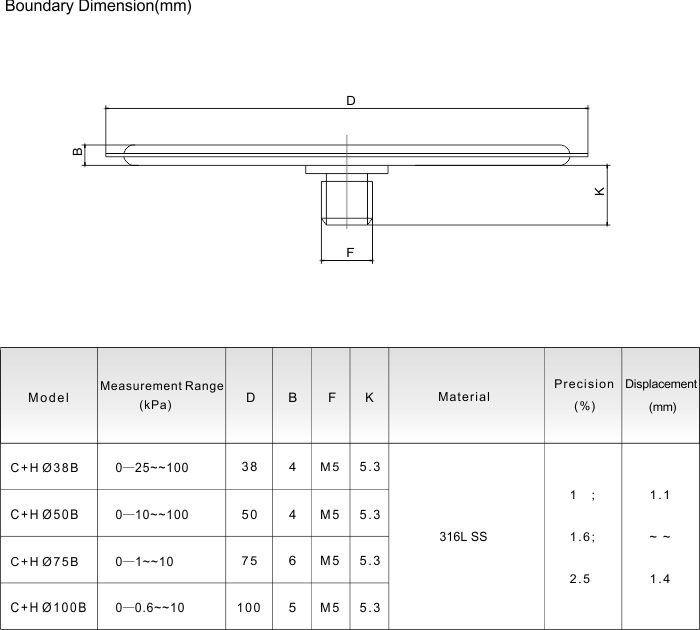

1. Temperature Range The gauge must be capable of operating effectively at ultra-low temperatures without losing accuracy. 2. Material Construction Materials used should be compatible with cryogenic fluids, typically involving stainless steel or other non-corrosive alloys to ensure durability and reliability.

3. Calibration and Accuracy Look for gauges that provide high-level accuracy and stability over time, as fluctuations can lead to serious operational issues.

4. Response Time Fast response times are crucial in dynamic systems where pressure can change rapidly.

5. Design and Size Compact designs can be beneficial in systems with limited space, while gauges with clear measurement displays facilitate monitoring.

Top Cryogenic Differential Pressure Gauges

best cryogenic differential pressure gauges

1. Brooks Instrument 250 Series Known for its precision and reliability, the Brooks 250 series features a robust stainless-steel construction designed for harsh cryogenic conditions. It offers digital or analog options, ensuring versatility and ease of use in various applications.

2. Omega Engineering DPG1000 The DPG1000 is an exemplary model known for its exceptional accuracy and wide temperature range. With a built-in digital display and a high degree of resolution, it is well-suited for laboratory or field applications where precision is required.

3. AW-Lake Company’s Series PDQ41 This gauge is tailored specifically for cryogenic applications, providing accurate measurements with a response time that is typically superior to many competitors. It is designed to withstand the rigors of continuous use in harsh environments.

4. Viatran 200 Series With proven performance in extreme conditions, the Viatran 200 series is built to withstand the challenges posed by cryogenic systems. Its unique design allows for effective measurement while minimizing temperature-induced deviations.

5. Keller America’s Series 21 This differential pressure transmitter is designed for both liquid and gas media. Known for its durability, it is an excellent choice for industrial applications, providing long-term reliability under cryogenic conditions.

Applications

Cryogenic differential pressure gauges are widely used in industries such as

- Aerospace Monitoring fuel systems and ensuring safe pressurization of cryogenic fuels. - Healthcare Supporting the storage and transportation of cryopreserved biological materials, where precise pressure monitoring is essential. - Energy In LNG operations, where accurate pressure readings are critical for maintaining system integrity.

Conclusion

The best cryogenic differential pressure gauges provide essential measurements that enhance safety and efficiency in low-temperature environments. By considering features such as material construction, temperature range, and accuracy, users can select the most suitable gauge for their specific applications. Investing in high-quality differential pressure gauges allows for improved process control, ultimately leading to optimized performance in various critical industries. With advancements in technology, these instruments continue to evolve, offering even greater reliability and precision for the challenges posed by cryogenic environments.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025