Νοέ . 11, 2024 08:54 Back to list

diaphragm pressure guage pricelist

Understanding Diaphragm Pressure Gauges Importance and Pricing

In a variety of industrial applications, understanding and measuring pressure accurately is vital. Pressure gauges are indispensable instruments used across numerous sectors, including oil and gas, pharmaceuticals, food and beverage, and water treatment. Among these instruments, diaphragm pressure gauges are particularly valued for their precision and reliability. In this article, we will explore diaphragm pressure gauges, their significance, and what you can expect regarding pricing in the market.

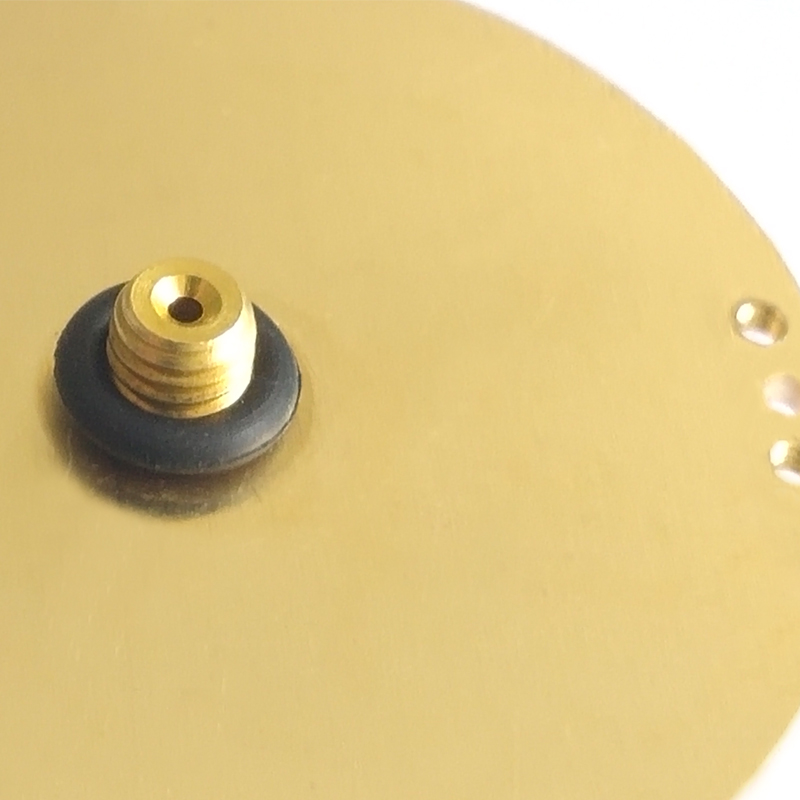

What is a Diaphragm Pressure Gauge?

A diaphragm pressure gauge operates using a diaphragm, a flexible membrane that responds to changes in pressure. The diaphragm bends in response to pressure fluctuations, and this mechanical movement is translated into a readable format, typically in units of psi (pounds per square inch) or bar. This design allows for the measurement of both static and fluctuating pressures, making diaphragm gauges suitable for a variety of applications where accurate pressure readings are crucial.

Applications of Diaphragm Pressure Gauges

Diaphragm pressure gauges are renowned for their versatility and robustness. Some common applications include

1. Process Industries Used for monitoring pressure in pipelines and vessels, ensuring operational safety and efficiency. 2. Food and Beverage Essential for monitoring processes in brewing and bottling, ensuring compliance with health and safety standards. 3. Pharmaceuticals Critical for maintaining the pressure within sterile environments during the manufacturing process to avoid contamination. 4. Power Plants Used in various systems to monitor pressures and prevent failures that can lead to costly downtimes.

Key Benefits of Diaphragm Pressure Gauges

1. Accuracy They provide accurate readings even in fluctuating pressure conditions. 2. Durability Designed to handle high-pressure environments and resist corrosion, ensuring longevity. 3. Low Maintenance With fewer moving parts compared to traditional gauges, diaphragm pressure gauges typically require less maintenance and are easier to calibrate.

Factors Affecting Pricing of Diaphragm Pressure Gauges

diaphragm pressure guage pricelist

When considering the purchase of diaphragm pressure gauges, several factors influence their pricing

1. Material of Construction The materials used to construct the diaphragm and the housing can significantly impact the cost. Materials such as stainless steel offer superior resistance to corrosive substances but come with a higher price tag.

2. Pressure Range Gauges designed for higher pressure ranges tend to be more expensive due to the additional engineering and materials required for safety and durability.

3. Accuracy Class Higher precision gauges, which provide more accurate readings, generally come at a higher cost.

4. Manufacturer and Brand Established brands known for quality and reliability might price their products higher than lesser-known manufacturers.

5. Customization Customized features, such as specific dial sizes, electrical output options, or additional certifications (like ATEX for hazardous environments), can also raise the price.

Estimated Price Ranges

While prices can vary widely based on the factors mentioned above, diaphragm pressure gauges generally range from $50 to $500 per unit. Basic models suitable for standard applications may begin around $50 to $100, while high-end, specialized models used in rigorous industrial environments can exceed $500. Custom features or gauges designed for extreme conditions can push the price even higher.

Conclusion

In conclusion, diaphragm pressure gauges are critical instruments in many industries, known for their accuracy, durability, and maintenance effectiveness. Their pricing is influenced by several factors, including materials used, pressure ranges, and manufacturer reputation. Understanding these aspects will help businesses and engineers make informed decisions when selecting the appropriate gauge for their application. Investing in a high-quality diaphragm pressure gauge can lead to improved process control, safety, and operational efficiency—a worthwhile consideration for any business reliant on accurate pressure monitoring.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025