Οκτ . 10, 2024 02:05 Back to list

diaphragm seal pressure gauge accuracy service

Understanding the Accuracy and Service of Diaphragm Seal Pressure Gauges

In various industrial applications, the accuracy and reliability of pressure measurements are critical for ensuring operational efficiency and safety. Among the devices used for this purpose, diaphragm seal pressure gauges have gained prominence due to their unique design and capabilities. This article will explore the accuracy and service considerations of diaphragm seal pressure gauges, emphasizing their importance in various industries.

What is a Diaphragm Seal Pressure Gauge?

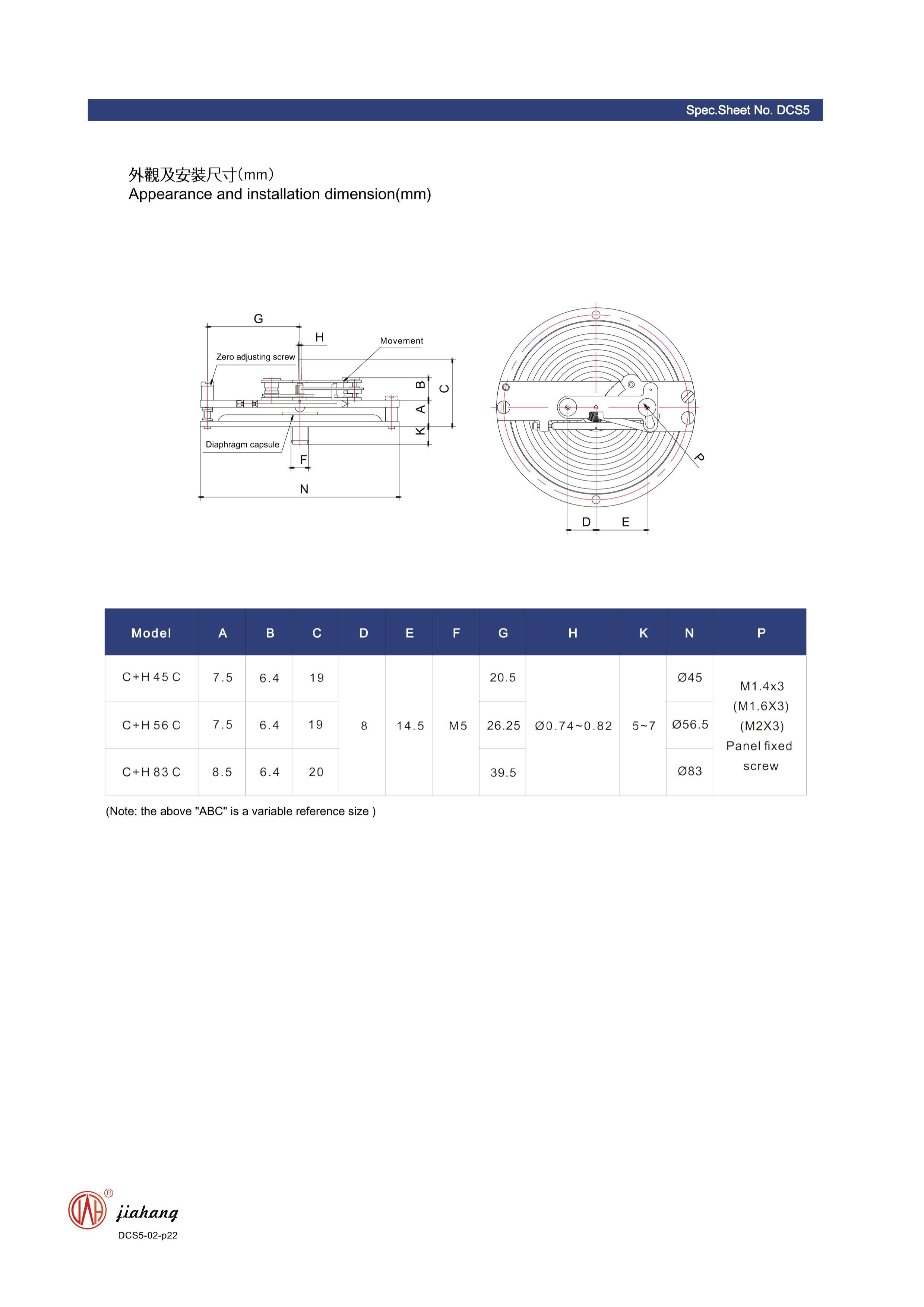

A diaphragm seal pressure gauge consists of a pressure gauge that is coupled with a diaphragm seal. The diaphragm separates the measuring element of the gauge from the process fluid, protecting it from harsh conditions such as high pressure, corrosive fluids, or extreme temperatures. This design allows the gauge to provide accurate readings without direct contact with the process media.

Importance of Accuracy

Accuracy is paramount when it comes to pressure measurements. A minor deviation can lead to significant problems, including equipment failure, safety hazards, or suboptimal operational performance. Diaphragm seal pressure gauges are designed to provide high accuracy due to their robust construction and the use of highly sensitive measuring elements.

The accuracy of a diaphragm seal pressure gauge can be influenced by various factors, including

1. Calibration Regular calibration is essential to maintain the accuracy of pressure gauges. Recalibration ensures that the gauge reflects the true pressure within the system and adheres to industry standards.

2. Installation The correct installation of the diaphragm seal pressure gauge is vital for accuracy. Improper installation can create inaccuracies due to factors like misalignment or external stresses.

3. Material Compatibility The materials used in the diaphragm and the gauge must be compatible with the process fluid. If the materials are not compatible, it can lead to diaphragm failure, which compromises the gauge's accuracy.

diaphragm seal pressure gauge accuracy service

4. Temperature and Pressure Ranges Diaphragm seal pressure gauges are designed for specific temperature and pressure ranges. Using a gauge beyond its specified limits can affect its accuracy and longevity.

Service Considerations

To ensure the optimal performance of diaphragm seal pressure gauges, regular service and maintenance are essential. This includes

1. Regular Inspections Routine inspections help identify potential issues before they become significant problems. During inspections, technicians should look for signs of wear, damage, or corrosion on the diaphragm and gauge body.

2. Cleaning If the process fluid is viscous or contains particulates, periodic cleaning might be necessary to prevent blockages and ensure accurate readings.

3. Seal Integrity The integrity of the diaphragm seal must be checked regularly. A compromised seal can lead to contamination of the measuring element, resulting in inaccurate readings and possible damage to the gauge.

4. Fluid Filling Many diaphragm seal pressure gauges utilize filling fluids to enhance performance. The filling fluid should be monitored and replenished as needed, as its properties can change over time, impacting measurement accuracy.

5. Replacement Eventually, diaphragm seal pressure gauges will require replacement due to wear or damage. Knowing when to replace a gauge is critical to avoid inaccurate readings and potential failures in processes relying on precise pressure measurements.

Conclusion

Diaphragm seal pressure gauges are essential tools in various industries, offering high accuracy and protection for measuring elements against harsh conditions. By understanding the factors that contribute to their accuracy and the necessary service practices, operators can ensure that these gauges perform reliably. Maintaining accurate pressure readings not only enhances operational efficiency but also contributes to the safety and longevity of the equipment and processes they monitor. Regular attention to calibration, installation, maintenance, and overall service can significantly extend the lifespan and accuracy of diaphragm seal pressure gauges, making them a valuable investment in any industrial setting.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025