Δεκ . 13, 2024 05:00 Back to list

differential pressure gauge p& exporters

Understanding Differential Pressure Gauges Key Features and Exporters

Differential pressure gauges are essential instruments used across various industries to measure the difference in pressure between two points in a system. This capability is fundamental for ensuring the safe and efficient operation of many processes, including those in HVAC systems, food and beverage production, chemical manufacturing, and oil and gas exploration. In this article, we will explore how differential pressure gauges work, their applications, and the landscape of exporters that provide these crucial devices.

What is a Differential Pressure Gauge?

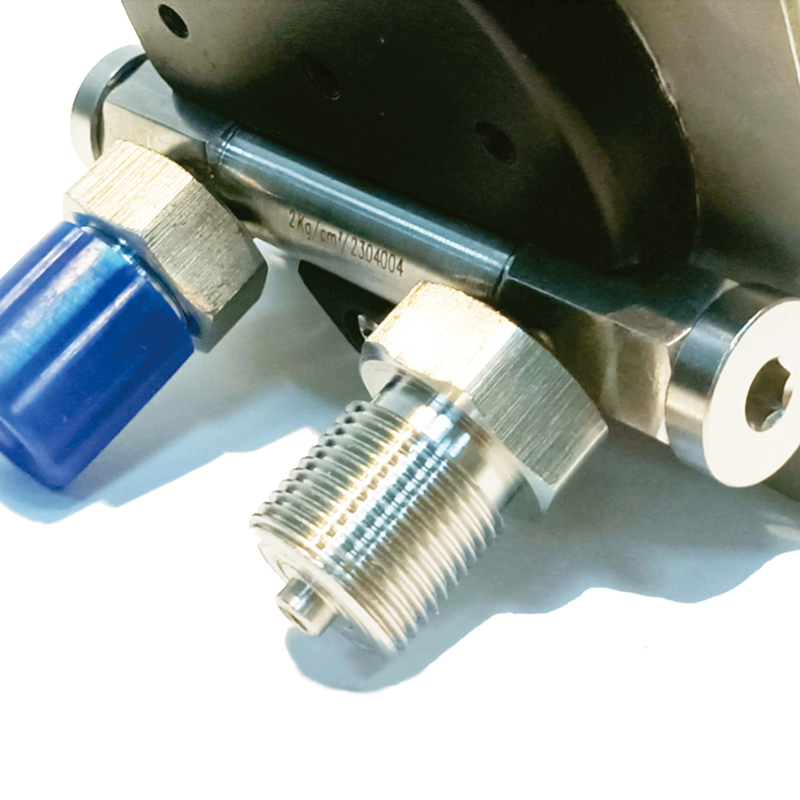

A differential pressure gauge is designed to measure the pressure difference between two points. It typically consists of two pressure ports connected to a sensing element, which can be a membrane, diaphragm, or another type of sensor. The gauge displays the differential pressure based on the force exerted by the fluid on each side of the sensing element. This reading helps operators detect problems such as blockages, leaks, or equipment failures.

How Differential Pressure Gauges Work

The working principle of a differential pressure gauge revolves around the balance of two pressures. When fluid enters the gauge through the two ports, the difference between the pressures creates a force on the sensing element. This force is translated into a mechanical reading, usually illustrated on a dial or an electronic display. There are various types of differential pressure gauges, including mechanical gauges, electronic gauges, and digital gauges, each with its specific advantages suited to different applications.

Mechanical gauges, for example, are often robust and can withstand harsh environments, making them suitable for industrial applications. On the other hand, electronic gauges offer higher precision and can provide digital outputs, which can integrate seamlessly into automated systems.

Applications of Differential Pressure Gauges

Differential pressure gauges are widely used in many sectors including

1. HVAC Systems In heating, ventilation, and air conditioning systems, these gauges monitor the pressure drop across filters and fans to ensure optimal performance and maintain air quality.

2. Oil and Gas Industry They are essential for monitoring pressure differentials in pipelines and systems to prevent leaks and ensure safe transportation of materials.

differential pressure gauge p& exporters

4. Water Treatment Facilities They are used to monitor the flow and filter pressures in water treatment systems, ensuring proper filtration and system efficiency.

5. Research and Laboratory Settings Here, precise measurements are critical for experimental setups and procedures, making reliable differential pressure gauges indispensable.

The Landscape of Exporters

In recent years, the demand for high-quality differential pressure gauges has grown globally, leading to an increase in the number of manufacturers and exporters. Countries with strong manufacturing capabilities, such as Germany, the USA, Japan, and China, are key players in the market.

Exporters must focus on several essential aspects to succeed in this competitive landscape

- Quality Standards Products must meet international quality standards such as ISO 9001 and others specific to the industry. This ensures reliability and safety across applications.

- Technological Advancements Keeping pace with technological evolution is crucial. Modern differential pressure gauges often incorporate digital displays, data logging features, and connectivity options that enhance their functionality.

- Customization Options Many applications require specific configurations in terms of materials, pressure ranges, and measurement capabilities. Successful exporters often provide customized solutions to meet diverse customer needs.

- Customer Support and Service Establishing good relationships with clients through reliable customer support, after-sales service, and training is essential for fostering trust and long-term partnerships.

- Market Research Understanding the specific requirements of different markets, including regulatory frameworks and customer preferences, can help exporters tailor their offerings effectively.

Conclusion

Differential pressure gauges play a crucial role in maintaining the efficiency and safety of various industrial processes. With a growing demand for these devices, exporters are presented with significant opportunities in global markets. By focusing on quality, technological innovation, customization, customer service, and market awareness, they can navigate the challenges of this competitive sector and meet the increasing global demand for reliable pressure measurement solutions. As industries continue to evolve, the importance of accurate and reliable differential pressure measurements will only grow, highlighting the ongoing relevance of these instruments in modern engineering and industrial applications.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025