Αυγ . 13, 2024 14:56 Back to list

Exploring the Advantages and Applications of Diaphragm Sealed Pressure Gauges in Various Industries

Understanding Famous Diaphragm-Sealed Pressure Gauges

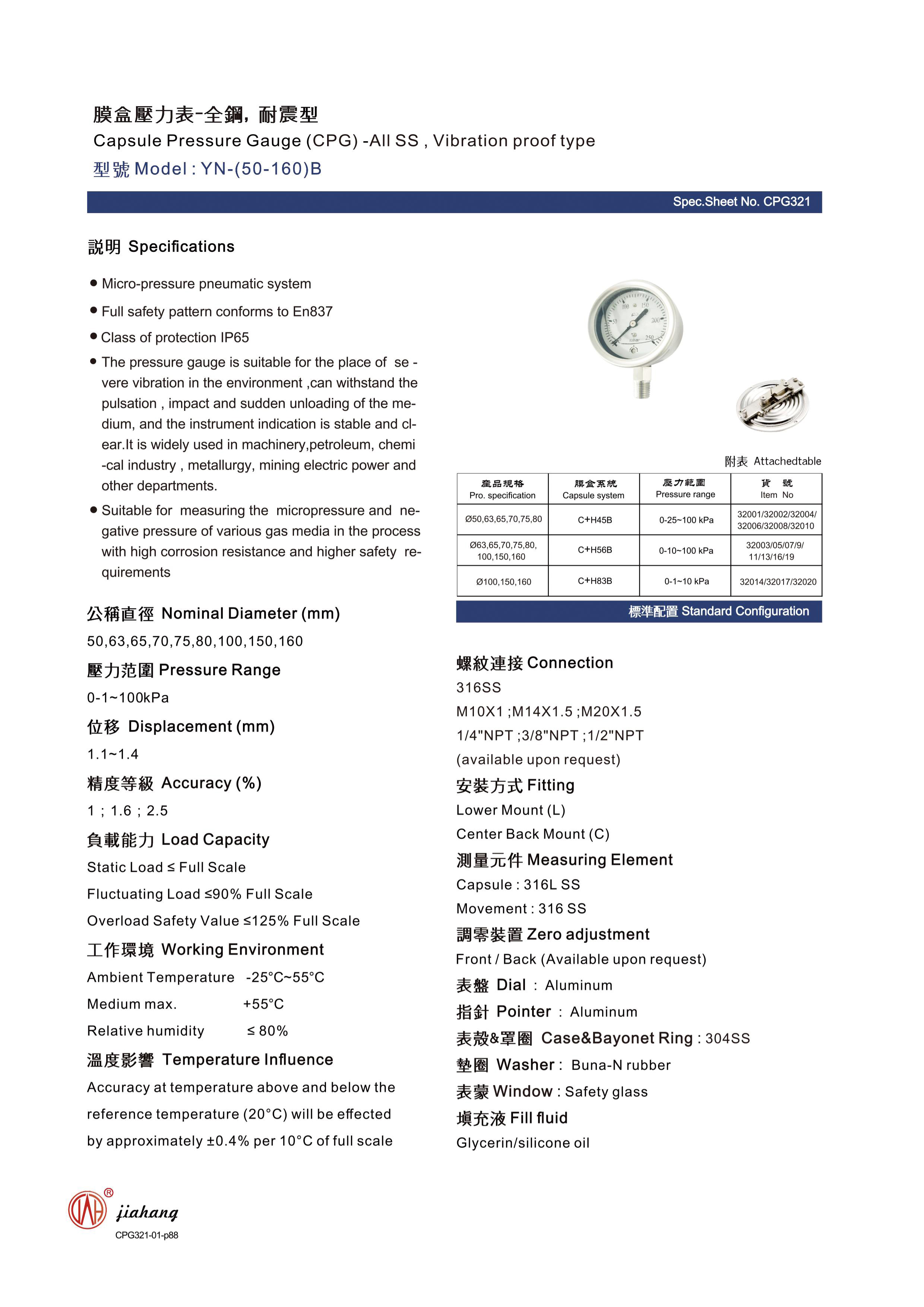

Pressure measurement is a fundamental aspect of many industrial processes, and among the various tools utilized, diaphragm-sealed pressure gauges have gained a reputation for their reliability and accuracy. These specialized gauges are designed to measure pressure in environments where the process fluid might be corrosive, viscous, or at high temperatures, making them essential across various sectors including oil and gas, chemical processing, and food and beverage manufacturing.

Understanding Famous Diaphragm-Sealed Pressure Gauges

One of the key advantages of diaphragm-sealed gauges is their performance in extreme conditions. For industries dealing with corrosive substances, the diaphragm's material can be chosen specifically for its resistance to the chemicals involved, preventing contamination of the measurement. In high-temperature applications, the gauge can be filled with a suitable fluid (such as silicone oil) to improve accuracy and damping, ensuring that rapid pressure fluctuations do not affect the reading.

famous diaphragm sealed pressure gauges

Famous brands in the industry, like Wika and Ashcroft, have developed a reputation for producing high-quality diaphragm-sealed pressure gauges trusted by engineers and operators worldwide. These companies focus on innovation and reliability, offering various configurations and customizations to meet specific industry needs. For instance, Wika's diaphragm-sealed gauges often feature a stainless-steel housing that is not only durable but also designed to meet stringent hygiene standards, making them ideal for the food and pharmaceutical industries.

The versatility of diaphragm-sealed pressure gauges extends to their application across various pressure ranges, from vacuum to high-pressure scenarios. This flexibility makes them suitable for a wide array of applications—from monitoring the pressure in pipelines to ensuring the integrity of pressure vessels.

Installation and maintenance of diaphragm-sealed pressure gauges are relatively straightforward, although some considerations must be addressed. Proper installation is crucial to avoid any potential leaks and maintain accurate readings. Moreover, regular calibration is recommended to ensure the gauges continue to perform accurately over time, especially in industries where precise measurements are critical for safety and compliance.

In conclusion, diaphragm-sealed pressure gauges represent a vital component in modern industrial measurement technology. Their ability to provide accurate pressure readings in challenging conditions makes them indispensable for many sectors. Leading manufacturers continue to innovate, developing robust solutions that meet the evolving needs of industries worldwide. As technology advances, we can expect these gauges to become even more sophisticated, further enhancing their role in process control and safety. For anyone involved in operations where pressure management is crucial, understanding and investing in high-quality diaphragm-sealed pressure gauges is a step towards ensuring efficiency and reliability in countless applications.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025