Νοέ . 27, 2024 03:20 Back to list

Wika ODM Differential Pressure Gauge for Accurate Measurement Solutions in Various Applications

Understanding ODM Differential Pressure Gauge by WIKA

In various industrial applications, precise measurement of differential pressure is crucial for ensuring optimal performance and safety. The ODM differential pressure gauge manufactured by WIKA stands out as a reliable instrument tailored to meet the demanding needs of various processes. This article delves into the features, applications, and benefits of utilizing WIKA's ODM differential pressure gauge.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument designed to measure the difference in pressure between two points within a system. It is instrumental in applications where pressure differences are critical for operational efficiency, such as in HVAC systems, filtration processes, and fluid flow monitoring. By providing accurate readings, these gauges help operators maintain desired conditions, prevent equipment failures, and optimize energy consumption.

Features of WIKA's ODM Differential Pressure Gauge

WIKA, known for its commitment to quality and innovation, has designed the ODM differential pressure gauge with several robust features

1. High Accuracy The ODM gauge is engineered for precision, ensuring that differential pressure readings are reliable and repeatable. This high level of accuracy is essential for critical applications where minute pressure variations can lead to significant consequences.

2. Durable Construction Built with high-quality materials, the ODM gauge is designed to withstand harsh environments. Its robust casing protects the internal components from physical damage and external elements, making it suitable for both indoor and outdoor applications.

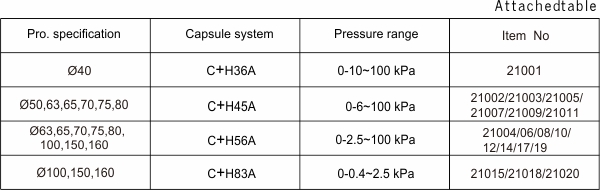

3. Wide Range of Measuring Ranges The ODM differential pressure gauge offers a variety of measuring ranges, allowing it to be tailored to specific applications. This flexibility makes it a versatile choice for industries such as pharmaceuticals, petrochemicals, and food production.

4. User-Friendly Design WIKA prioritizes user experience; hence the ODM gauge features a clear, easy-to-read dial and intuitive markings. This design minimizes the risk of misinterpretation of readings, enhancing operational safety and efficiency.

odm differential pressure gauge wika

5. Versatile Connection Options The gauge supports multiple connection types, making it compatible with various systems. This adaptability simplifies installation and integration into existing setups.

6. Maintenance-Free Operation With a robust design and high-quality components, the ODM differential pressure gauge requires minimal maintenance. This feature contributes to lower operational costs and increased uptime, making it a cost-effective solution.

Applications of ODM Differential Pressure Gauge

The ODM differential pressure gauge is suitable for numerous applications across various industries

1. HVAC Systems Monitoring air pressure differences in heating, ventilation, and air conditioning systems is critical for ensuring efficient performance. The ODM gauge helps in maintaining optimal airflow and pressure balance.

2. Filtration Systems In filtration applications, maintaining the proper pressure differential is crucial for ensuring effective filter performance and longevity. The ODM gauge provides timely readings that allow operators to perform necessary maintenance tasks.

3. Chemical Processing In chemical manufacturing, precise control of pressure differences can significantly influence reaction rates and product quality. The ODM differential pressure gauge allows for real-time monitoring, ensuring processes remain within specified parameters.

4. Water and Wastewater Treatment The gauge can also be utilized in water treatment facilities to monitor pressure differentials across filters and membranes, ensuring efficiency and compliance with health and safety standards.

Conclusion

WIKA’s ODM differential pressure gauge is a vital tool for industries that demand precision in pressure monitoring. With features that ensure accuracy, durability, and user-friendliness, it addresses the unique challenges faced in various applications. By investing in high-quality instruments like the ODM gauge, businesses can enhance operational efficiency, ensure safety, and optimize system performance. Whether in HVAC systems, chemical processing, or filtration, the ODM differential pressure gauge by WIKA proves itself as an indispensable asset in modern industry.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025