Οκτ . 09, 2024 04:45 Back to list

odm pressure gauge diaphragm type

Understanding the ODM Pressure Gauge Diaphragm Type

Pressure measurement is a critical component in various industrial processes, ensuring safety, efficiency, and optimal performance. Among the various types of pressure gauges available, the ODM (Over-Dimensioned Manifold) pressure gauge, particularly the diaphragm type, stands out due to its unique construction and functionality. This article delves into the workings, advantages, and applications of diaphragm type ODM pressure gauges.

What is a Diaphragm Pressure Gauge?

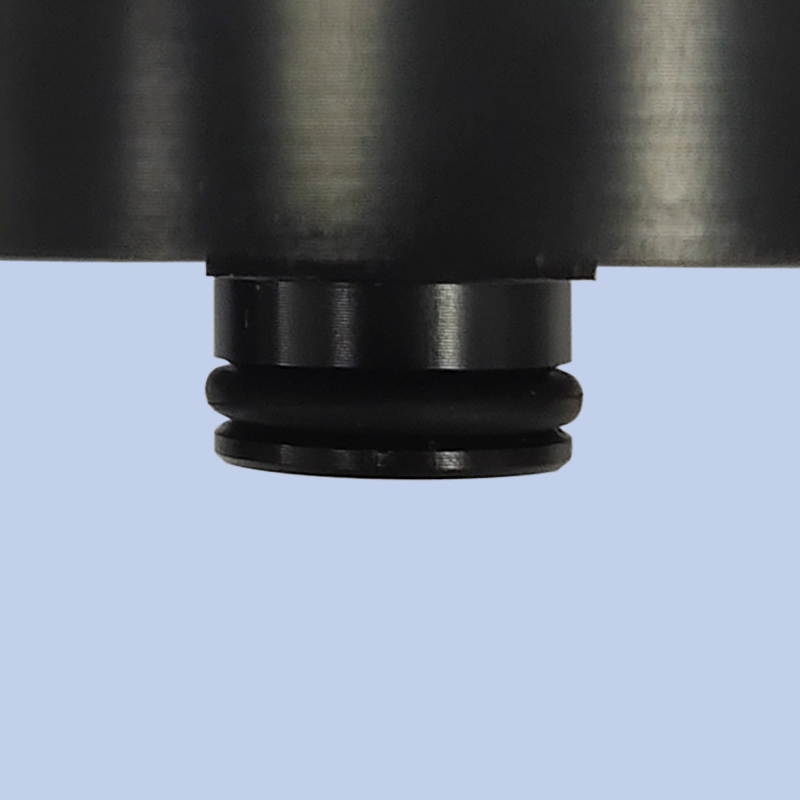

A diaphragm pressure gauge utilizes a flexible diaphragm to measure pressure. The diaphragm is a thin, flexible membrane often made of materials such as stainless steel, rubber, or other elastomers. When pressure is applied from one side of the diaphragm, it causes the diaphragm to deform. This deformation is then transmitted through a mechanism, usually a series of linkages and levers, to a pointer that indicates the pressure reading on a dial or digital display.

How Does the ODM Diaphragm Pressure Gauge Work?

The ODM diaphragm pressure gauge operates under the principle of deflection. When fluid pressure pushes against the diaphragm, the diaphragm bends. The extent of this bending correlates directly with the pressure applied. The movement is magnified and transmitted to a spring-loaded mechanism that converts this movement into an accurate pressure reading.

One of the key features of the ODM design is its extensive manifold, which allows for a more stable and precise reading. This design minimizes the effects of pressure fluctuations and vibrations that can often lead to inaccurate readings in other types of gauges. The combination of a diaphragm and a well-engineered manifold results in a gauge that can provide reliable data even in challenging environments.

Advantages of Diaphragm Pressure Gauges

1. High Sensitivity Diaphragm pressure gauges are known for their sensitivity, making them ideal for measuring low pressures accurately. This is crucial in applications where precise pressure control is necessary.

2. Corrosion Resistance Many diaphragm gauges can be constructed from corrosion-resistant materials, enabling their use in harsh environments or with corrosive fluids. This extends their lifespan and reduces maintenance requirements.

odm pressure gauge diaphragm type

4. Low Maintenance Diaphragm pressure gauges typically require minimal maintenance due to their robust construction and the absence of moving parts that are prone to wear.

5. Versatility These gauges can be used in various applications, including HVAC systems, fuel systems, and water treatment processes, making them highly versatile.

Applications of ODM Diaphragm Pressure Gauges

Diaphragm pressure gauges find applications across numerous industries. Some notable examples include

- Oil and Gas Used to monitor pressures in pipelines and storage tanks to ensure safe and efficient operations. - Pharmaceuticals Essential for maintaining precise pressure levels in processes where product safety and quality are paramount.

- Food and Beverage Employed in the processing and packaging stages to monitor pressure and ensure product integrity.

- Manufacturing Used in equipment and machinery where pressure levels must be maintained within specific thresholds for optimal operation.

Conclusion

In conclusion, the ODM diaphragm pressure gauge represents a sophisticated solution for pressure measurement in various industries. Its sensitive and reliable design, coupled with the advantages of durability and maintenance simplicity, make it an ideal choice in demanding environments. Whether used in oil and gas, pharmaceuticals, or food production, the diaphragm type ODM pressure gauge not only enhances safety and performance but also stands as a testament to the engineering advancements in measurement technology. For industries that rely on accurate pressure readings, investing in a high-quality diaphragm pressure gauge can lead to significant operational efficiencies and a safer working environment.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025