Φεβ . 05, 2025 06:30 Back to list

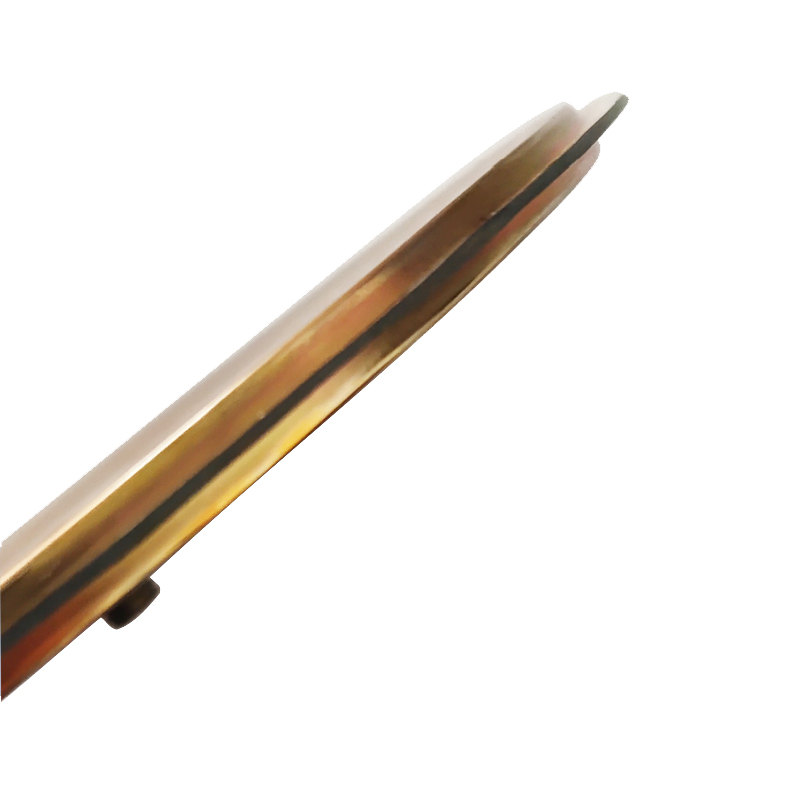

Diaphragm Capsule Pressure Gauge(CPG)-Medical Type (Night Vision) YEY-50

Selecting the most suitable OEM diaphragm material pressure gauge is crucial for industries requiring precise pressure monitoring in demanding environments. These specialized gauges are integral in pharmaceutical, petrochemical, and food processing industries, where maintaining accuracy under harsh conditions is essential.

4. PTFE (Polytetrafluoroethylene) Known widely by the brand name Teflon, PTFE is used for its non-reactive properties. It provides a high resistance to a wide range of chemicals. PTFE diaphragms are a fitting choice for applications where product purity and non-contamination are paramount. 5. Monel This nickel-copper alloy is resistant to corrosion in seawater and steam at high temperatures. The oil and gas industry often relies on Monel diaphragms for applications requiring longevity and reliability in marine environments. When choosing an OEM diaphragm material pressure gauge, the specific application, media properties, and environmental conditions should define the material selection. Factors such as operating temperature, pressure range, and potential exposure to media should all feed into the decision-making process. It's also crucial to collaborate with experienced OEM suppliers that have proven expertise in manufacturing diaphragm pressure gauges. These specialists offer invaluable knowledge in selecting appropriate materials that meet industry standards such as ASTM, ANSI, and ISO. A reliable OEM partner can help tailor a pressure gauge solution that ensures precision, durability, and safety in your specific application. Investing time in understanding these factors and collaborating with knowledgeable OEM partners establishes a foundation of authoritativeness and trustworthiness in your operational infrastructure. With the accurate and reliable performance of diaphragm pressure gauges, businesses can not only achieve operational excellence but also ensure compliance with regulatory requirements. Finally, monitoring emerging trends and innovations in diaphragm materials can provide competitive advantages and potentially new applications for pressure gauges across diverse industries. Keeping abreast of material advancements ensures that your business remains at the forefront of pressure measurement technology and continues to uphold high standards of performance and reliability.

4. PTFE (Polytetrafluoroethylene) Known widely by the brand name Teflon, PTFE is used for its non-reactive properties. It provides a high resistance to a wide range of chemicals. PTFE diaphragms are a fitting choice for applications where product purity and non-contamination are paramount. 5. Monel This nickel-copper alloy is resistant to corrosion in seawater and steam at high temperatures. The oil and gas industry often relies on Monel diaphragms for applications requiring longevity and reliability in marine environments. When choosing an OEM diaphragm material pressure gauge, the specific application, media properties, and environmental conditions should define the material selection. Factors such as operating temperature, pressure range, and potential exposure to media should all feed into the decision-making process. It's also crucial to collaborate with experienced OEM suppliers that have proven expertise in manufacturing diaphragm pressure gauges. These specialists offer invaluable knowledge in selecting appropriate materials that meet industry standards such as ASTM, ANSI, and ISO. A reliable OEM partner can help tailor a pressure gauge solution that ensures precision, durability, and safety in your specific application. Investing time in understanding these factors and collaborating with knowledgeable OEM partners establishes a foundation of authoritativeness and trustworthiness in your operational infrastructure. With the accurate and reliable performance of diaphragm pressure gauges, businesses can not only achieve operational excellence but also ensure compliance with regulatory requirements. Finally, monitoring emerging trends and innovations in diaphragm materials can provide competitive advantages and potentially new applications for pressure gauges across diverse industries. Keeping abreast of material advancements ensures that your business remains at the forefront of pressure measurement technology and continues to uphold high standards of performance and reliability.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025