Νοέ . 01, 2024 07:30 Back to list

OEM Dual Diaphragm Differential Pressure Gauges for Precision Measurement Solutions

Understanding OEM Dual Diaphragm Differential Pressure Gauges

In industrial applications, the measurement of differential pressure is critical for ensuring optimal performance and safety. Among the various instruments available, OEM dual diaphragm differential pressure gauges stand out for their reliability and precision. These gauges are essential in processes where pressure differences must be accurately monitored to maintain the efficiency of systems such as filtration, liquid flow, and gas distribution.

A differential pressure gauge measures the pressure difference between two points in a system, which can indicate the condition of filters, levels of fluid in tanks, or the functioning of pumps. The OEM dual diaphragm design enhances this functionality by incorporating two separate diaphragm elements. This dual configuration provides greater accuracy and stability in readings, particularly in challenging environments where vibrations, temperature fluctuations, and other external factors can interfere with performance.

One of the significant advantages of dual diaphragm gauges is their ability to handle a wide range of fluids, including corrosive liquids and gases. The diaphragms are typically made of materials resistant to chemical degradation, ensuring longevity and reliability even under harsh conditions. As a result, OEM dual diaphragm differential pressure gauges are commonly found in industries such as oil and gas, chemical processing, food and beverage production, and water treatment facilities.

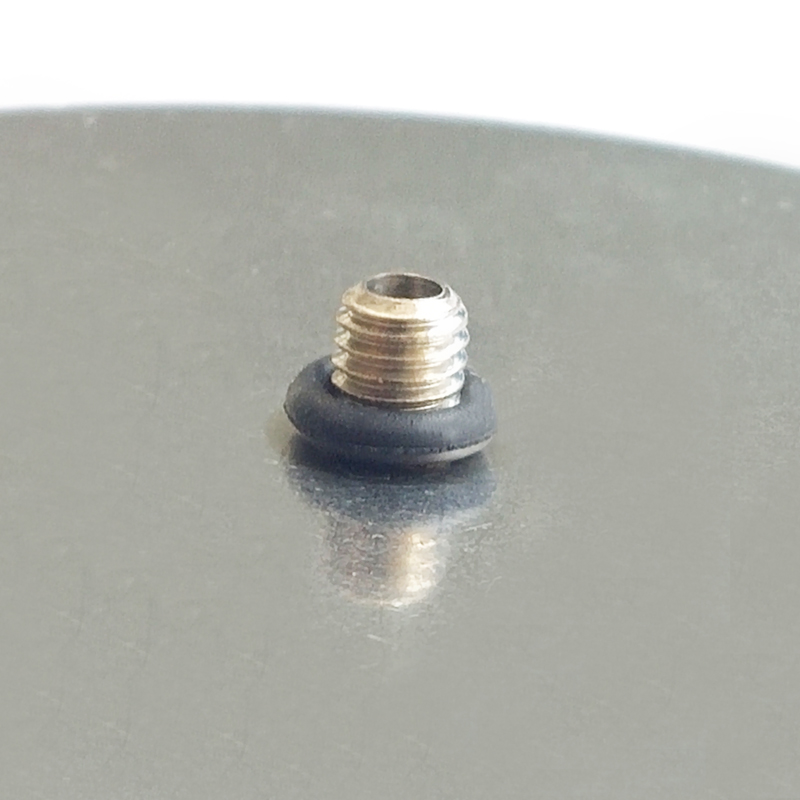

oem dual diaphragm differential pressure gauges

Another benefit of using OEM dual diaphragm differential pressure gauges is their low maintenance requirement. The design minimizes the risk of leaks and mechanical failure, reducing the need for frequent servicing or replacements. This feature is especially beneficial for manufacturers and operators who aim to minimize downtime in their operations.

Moreover, these gauges often come with options for additional features, such as electrical outputs for easy integration into control systems, making it easier to monitor and collect data in real-time. This capability supports modern industry trends towards automation and data-driven decision-making, providing operators with the insights needed to optimize processes further.

When selecting an OEM dual diaphragm differential pressure gauge, it is essential to consider factors such as the range of pressure measurement, the type of media being measured, and the environmental conditions in which the gauge will operate. By carefully matching the gauge specifications to the application requirements, operators can ensure accuracy and reliability, leading to improved productivity and safety.

In summary, OEM dual diaphragm differential pressure gauges are vital tools in various industrial applications. Their reliable performance, low maintenance, and adaptability to different environments make them an excellent choice for professionals seeking precise pressure monitoring solutions. As industries continue to evolve, the demand for advanced measurement instruments like these will undoubtedly increase, ensuring critical processes operate smoothly and efficiently.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025