Οκτ . 07, 2024 06:38 Back to list

precision differential pressure gauge factory

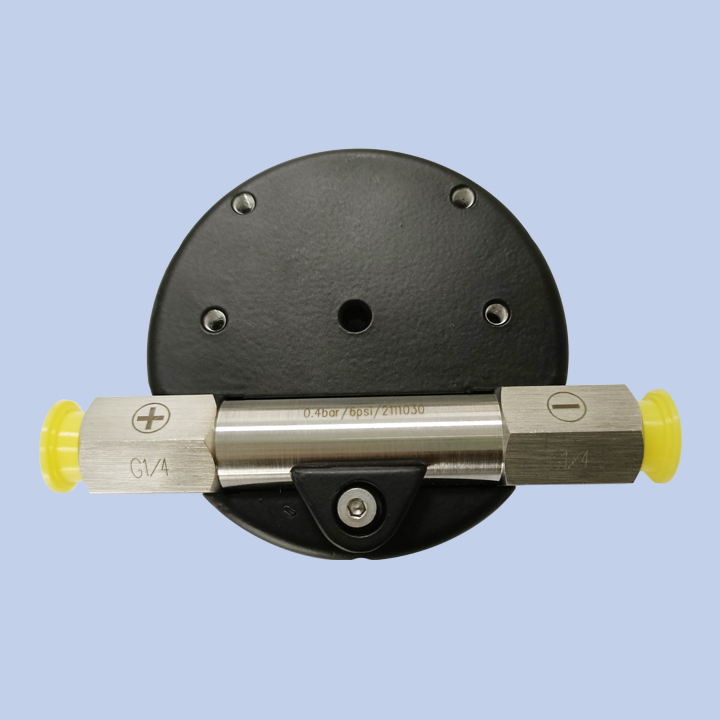

Precision Differential Pressure Gauge An Overview

In a variety of industrial applications, monitoring and controlling pressure is crucial for the efficiency and safety of operations. Among the devices that play a critical role in this regard is the precision differential pressure gauge. This instrument is designed to measure the difference in pressure between two points within a system, providing essential data that can impact operational efficiency and product quality.

What is a Differential Pressure Gauge?

A differential pressure gauge essentially compares two pressure measurements—one from the process being monitored and another from a reference point, usually atmospheric pressure or a pressure from another part of the system. The result is a reading that represents the difference in pressure (hence differential), which can indicate flow rates, filter conditions, and system performance, among other factors.

Importance of Precision

Precision is key when it comes to pressure measurements. In many applications, even minute deviations in pressure readings can lead to significant issues, including equipment malfunction, product inconsistencies, and safety hazards. Thus, precision differential pressure gauges are engineered to deliver accurate, reliable measurements that businesses can trust.

High-quality materials, advanced calibration processes, and robust design contribute to the precision of these gauges. Many manufacturers utilize state-of-the-art technology, including digital readouts and microprocessor-based sensing elements, to enhance accuracy and provide real-time data. Additionally, calibration practices are critical; regular calibration ensures that the gauge maintains its accuracy over time, which is essential in industries such as pharmaceuticals, food and beverage, and petrochemicals.

Applications of Precision Differential Pressure Gauges

precision differential pressure gauge factory

The applications of precision differential pressure gauges are vast and varied. In the pharmaceutical industry, for instance, precise pressure measurements are vital to maintain controlled environments and ensure that products are manufactured within specified parameters. In wastewater treatment facilities, these gauges help monitor filters and pumps, ensuring that systems operate efficiently and environmental regulations are met.

In HVAC (Heating, Ventilation, and Air Conditioning) systems, differential pressure gauges help to monitor airflow and ensure that air filters are not clogged, which can impede system performance. Furthermore, industries employing pneumatic or hydraulic systems rely on these gauges to ensure consistent operation and prevent system failures.

The Manufacturing Process

The manufacturing of precision differential pressure gauges involves meticulous design and engineering processes. Factories focus on sourcing high-quality materials such as stainless steel, which ensures durability and resistance to corrosive environments. Advanced manufacturing techniques, including CNC machining and automated assembly processes, are employed to maintain precision in every component of the gauge.

Quality assurance is a cornerstone of the manufacturing process. Each gauge is subjected to rigorous testing procedures, including temperature and pressure tests, to ensure that they meet stringent industry standards before being shipped to customers. This commitment to quality not only enhances the reliability of the gauges but also builds trust with consumers.

Conclusion

In conclusion, precision differential pressure gauges play an indispensable role across various industries by providing crucial measurements that facilitate safety, efficiency, and product quality. The focus on precision in manufacturing ensures that these gauges perform accurately, thereby serving as a pivotal tool in modern industrial operations. As technology continues to advance, we can expect even more innovations in pressure measurement, enhancing the capabilities of these essential instruments further. Industries that prioritize quality and precision in their processes will undoubtedly benefit from the integration of these sophisticated devices into their systems.

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025