Νοέ . 06, 2024 14:45 Back to list

Wholesale Diaphragm Sealed Pressure Gauges for Accurate Measurement Solutions

Understanding Wholesale Diaphragm Sealed Pressure Gauges

In the world of industrial instrumentation, pressure gauges play a pivotal role in monitoring and controlling various processes. Among the many types of pressure gauges available, diaphragm sealed pressure gauges are particularly noteworthy due to their ability to provide accurate readings in challenging environments. This article explores the essential features, applications, advantages, and considerations associated with wholesale diaphragm sealed pressure gauges.

What is a Diaphragm Sealed Pressure Gauge?

A diaphragm sealed pressure gauge is a specialized instrument designed to measure the pressure of gases and liquids in a system while being isolated from the media being measured. This is achieved through a flexible diaphragm that separates the measuring element from the pressure source. When pressure is applied to the diaphragm, it deforms, causing a movement that translates into a pressure reading on the gauge.

Key Features

1. Isolation from Process Media One of the primary advantages of diaphragm sealed pressure gauges is their ability to isolate the sensing element from aggressive, corrosive, or viscous media. This isolation prolongs the life of the gauge and reduces maintenance needs. 2. Various Media Compatibility These gauges can handle a wide range of media, including high-temperature fluids, corrosive chemicals, and even slurries, making them versatile for various applications.

3. Accuracy and Precision The design of diaphragm sealed gauges often allows for high accuracy and precision, crucial for applications where minute changes in pressure can significantly impact processes.

4. Different Designs Suppliers offer various designs, including stainless steel and plastic housings, to meet diverse industry needs and environmental conditions.

Applications

Diaphragm sealed pressure gauges are widely used across various industries, including

- Chemical Processing In chemical plants, these gauges monitor pressure levels of hazardous chemicals while protecting the measuring element from corrosive effects.

- Food and Beverage They help monitor pressures in food processing equipment without contaminating the product, crucial for meeting hygiene standards.

- Pharmaceuticals In pharmaceutical manufacturing, diaphragm sealed gauges ensure sterile conditions are maintained while monitoring system pressures.

- Oil and Gas These gauges are crucial for measuring pressures in high-temperature and high-pressure environments, such as pipelines and drilling operations.

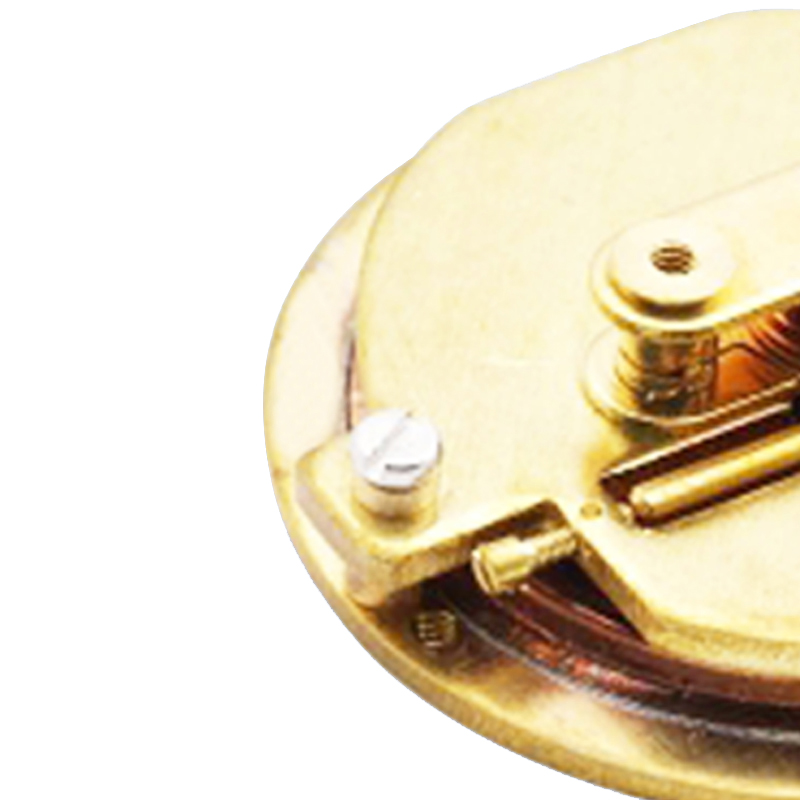

wholesale diaphragm sealed pressure gauge

Advantages of Wholesale Purchase

Purchasing diaphragm sealed pressure gauges wholesale presents several advantages

1. Cost Efficiency Wholesale prices can lead to significant savings for businesses, especially when purchasing in bulk for large projects or operations.

2. Supplier Relationships Establishing connections with wholesale suppliers can lead to better customer service, tailored solutions, and potential discounts on future orders.

3. Consistency in Quality Wholesale transactions often guarantee a consistent supply of high-quality instruments, minimizing the risk of discrepancies in pressure measurements across multiple gauges.

4. Access to Latest Technologies Wholesale suppliers typically have access to the newest technologies and innovations in pressure measurement, ensuring that businesses can utilize the latest advancements.

Considerations When Selecting Diaphragm Sealed Pressure Gauges

When selecting diaphragm sealed pressure gauges, several factors should be taken into consideration

- Process Conditions Understand the application’s temperature, pressure range, and compatibility with the media involved to select an appropriate gauge.

- Material Selection Choose materials that resist corrosion and wear to ensure longevity, especially if dealing with aggressive substances.

- Calibration and Maintenance Regular calibration and maintenance are essential for optimal performance. Ensure that suppliers offer support for these services.

- Readability and Features Consider the readability of the gauge, including the size and design of the dial, as well as any additional features like digital displays or alarm systems.

Conclusion

Wholesale diaphragm sealed pressure gauges are indispensable tools in various industrial applications for monitoring gas and liquid pressures. Their unique design allows for safe and reliable operation under challenging conditions while offering businesses cost savings and consistency when purchased in bulk. By considering the specific requirements of their processes, industries can select the most suitable diaphragm sealed pressure gauges to ensure operational efficiency and safety. As technology continues to evolve, so too will the capabilities of these essential measurement instruments, reinforcing their critical role across sectors.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025