Dic . 03, 2024 11:17 Back to list

capillary diaphragm seal pressure gauge factories

Understanding Capillary Diaphragm Seal Pressure Gauges A Comprehensive Overview

Capillary diaphragm seal pressure gauges are critical components in various industrial applications, where precise measurement and monitoring of pressure are crucial. These gauges are specifically designed to handle challenging environments, ensuring accurate readings even in the presence of high temperatures, corrosive substances, and viscous fluids. This article explores how capillary diaphragm seal pressure gauges function, their applications, and the advantages they offer.

What is a Capillary Diaphragm Seal Pressure Gauge?

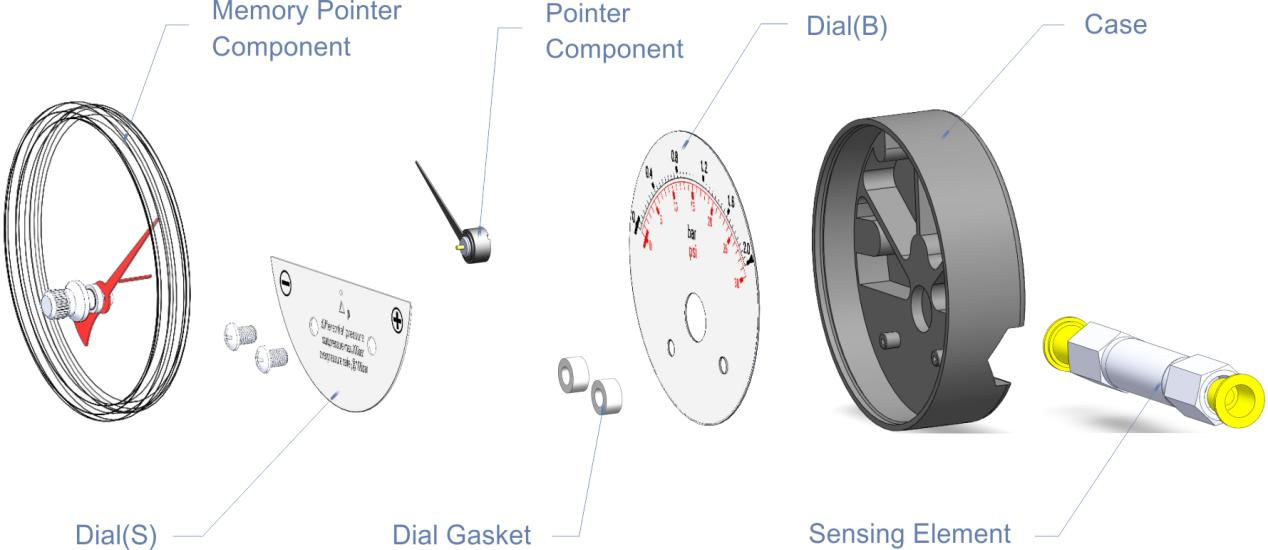

A capillary diaphragm seal pressure gauge comprises several key components a diaphragm, a capillary tube, and a pressure gauge itself. The diaphragm is a flexible barrier that responds to changes in pressure, while the capillary tube allows for the transmission of this pressure change to the gauge without direct contact with the process media.

The design of the diaphragm seal is critical. It prevents the measuring instrument from coming into contact with any corrosive or contaminated fluids, thus ensuring long-term reliability and accuracy. The diaphragm flexes in response to pressure changes, converting this mechanical movement into a readable gauge indication.

How Does It Work?

When the pressure of a fluid or gas alters, the diaphragm deflects. This movement creates a change in pressure within the capillary tube connected to the pressure gauge. The gauge then translates this change into a corresponding pressure reading. This design effectively isolates the pressure measurement from the effects of the process environment, which is particularly beneficial in harsh conditions where traditional gauges might fail.

Applications of Capillary Diaphragm Seal Pressure Gauges

These gauges are widely used across various industries, including

2. Oil and Gas In upstream and downstream processes, maintaining accurate pressure measurements is vital for safety and efficiency, making diaphragm seal gauges essential.

capillary diaphragm seal pressure gauge factories

3. Food and Beverage The hygienic design of these gauges allows for safe application in processes that require strict sanitary standards.

4. Pharmaceuticals For processes where contamination can lead to costly recalls or safety issues, these gauges help maintain the integrity of measurements.

5. Power Generation In both renewable and non-renewable energy sectors, monitoring pressure in steam systems and other processes is critical for optimal performance and safety.

Advantages of Capillary Diaphragm Seal Pressure Gauges

Capillary diaphragm seal pressure gauges offer numerous advantages, such as

- Protection from Process Media The primary benefit is their ability to isolate the gauge from harsh process conditions, extending the gauge's lifespan.

- Accurate Measurements By preventing corrosive and viscous materials from contacting the measuring instrument, the gauges provide more reliable and consistent readings.

- Versatility These gauges can handle a wide range of temperatures and pressures, making them suitable for diverse applications.

- Remote Sensing The capillary design allows for remote placement of the gauge, facilitating easier installation and maintenance in hard-to-reach areas.

Conclusion

Capillary diaphragm seal pressure gauges are indispensable in industries where harsh environments and corrosive substances are prevalent. Their robust construction, combined with the ability to provide accurate and reliable pressure measurements, makes them a preferred choice for engineers and technicians alike. As industries continue to evolve, the importance of precision and safety in pressure monitoring will only grow, reinforcing the need for advanced instruments like capillary diaphragm seal pressure gauges. Their role in ensuring operational efficiency and safety cannot be overstated, as they contribute significantly to enhanced productivity and reduced risk across industrial applications.

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025