Oct . 09, 2024 21:15 Back to list

custom diaphragm material pressure gauge

Understanding Custom Diaphragm Material for Pressure Gauges

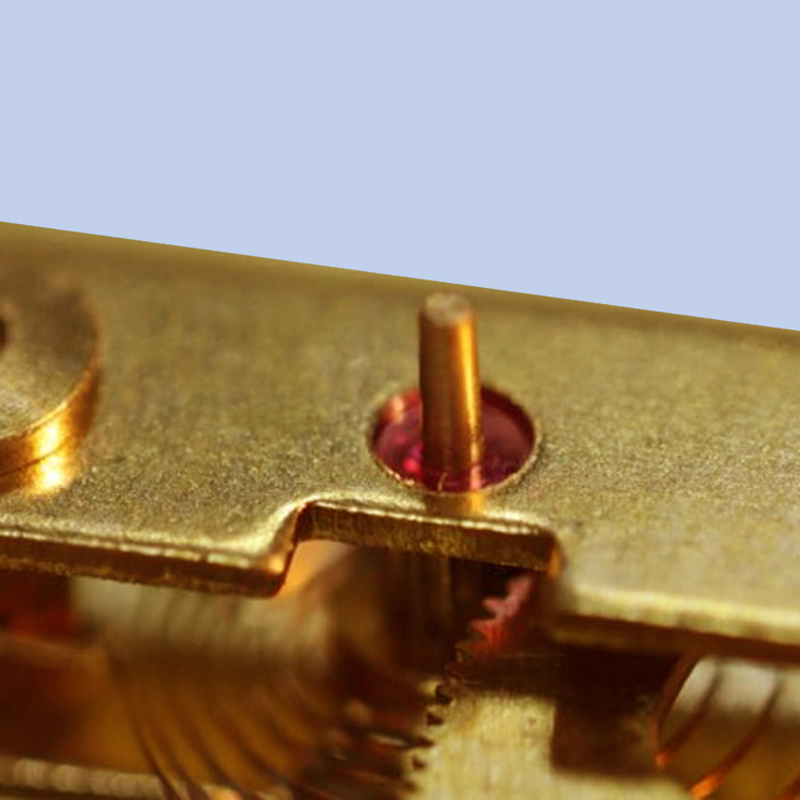

Pressure gauges are ubiquitous instruments utilized across various industries to monitor the pressure of gases and liquids within a system. They come in various designs, but the heart of many pressure gauges is the diaphragm – a flexible membrane that responds to pressure changes. The material used for this diaphragm is crucial because it determines not only the accuracy and reliability of the gauge but also its longevity and performance under specific environmental conditions. In this article, we will explore the significance of custom diaphragm materials in pressure gauges, and how they can be tailored to meet specific industry needs.

The Role of the Diaphragm

At the core of a pressure gauge, the diaphragm converts pressure variations into mechanical movement, which then translates into a readable metric on the gauge's dial or display. As pressure is applied, the diaphragm flexes, causing a pointer to move across a calibrated scale. The sensitivity and responsiveness of this mechanism are heavily influenced by the material and design of the diaphragm.

Importance of Material Selection

Selecting the right diaphragm material is critical for several reasons

1. Chemical Compatibility Different applications involve different fluids, some of which can be corrosive. For example, a gauge used in a chemical processing plant may need a diaphragm made from materials such as Teflon or certain alloys that can withstand aggressive chemicals. Customizing the material ensures that it will not degrade or react adversely with the measured substance.

2. Temperature Resistance Pressure systems often operate in extreme conditions. Materials need to be chosen not only for their chemical resistance but also for their ability to withstand high temperatures or freeze at low temperatures. Custom diaphragm materials can be engineered to maintain functionality across a wider temperature range.

3. Pressure Range Different applications require gauging different pressure ranges. The mechanical properties of the diaphragm material dictate how much pressure it can withstand without failing or yielding. Custom designs allow for optimizing the thickness and elasticity of the diaphragm to accommodate specific pressure ranges.

custom diaphragm material pressure gauge

4. Accuracy and Precision Materials with better elasticity and fatigue resistance contribute to more accurate and precise readings. Custom materials can be selected to minimize hysteresis and improve the repeatability of the gauge.

5. Mechanical Stress When subjected to pressure, the diaphragm experiences mechanical stress. If the chosen material is not suitable, it can lead to premature failure and inaccurate readings. Custom diaphragm materials can be selected based on their mechanical properties to handle the stress levels expected in a given application.

Customization in Diaphragm Materials

The ability to customize diaphragm materials opens up a myriad of possibilities for engineers and product designers. Composite materials, for instance, can combine the best attributes of different substances to create a diaphragm that is lightweight yet strong, resistant to corrosion, and capable of operating in challenging environments.

For applications involving cryogenic conditions, special polymers or metals with low thermal conductivity might be used, while high-temperature settings may call for specialized alloys or silicone-based materials. Custom composites not only enhance performance but can also help in reducing costs and improving the overall lifecycle of the pressure gauge.

Conclusion

The significance of custom diaphragm materials in pressure gauges cannot be overstated. The right choice impacts not only the accuracy and reliability of the instrument but also its ability to perform under specific conditions and environments. As industries evolve and new applications arise, the demand for customized solutions has never been greater. Engineers and manufacturers must prioritize the selection of appropriate diaphragm materials tailored to their specific requirements, ensuring the longevity and effectiveness of pressure gauges in their applications.

In the complex world of fluid and gas measurement, understanding and implementing the right custom diaphragm material is essential for maintaining operational integrity and precision, making it a foundational element in the design and function of pressure gauges.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025