Dic . 06, 2024 13:48 Back to list

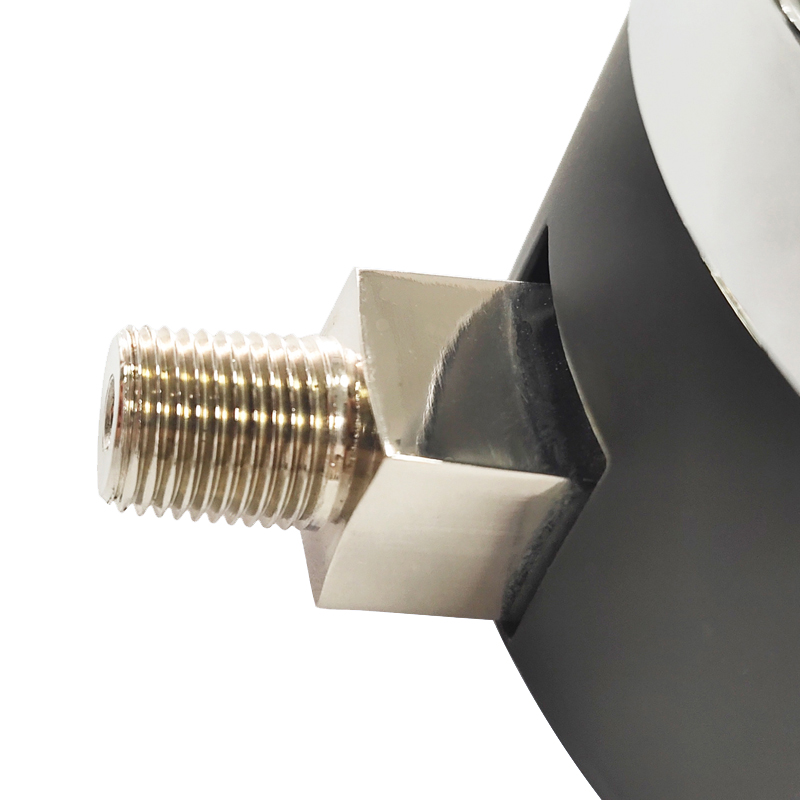

Custom Pressure Gauge with Flanged Diaphragm Seal for Accurate Measurements

Understanding Custom Flanged Diaphragm Seal Pressure Gauges

In industrial applications, accurate pressure measurement is crucial for maintaining safety and efficiency. A common solution for challenging environments is the custom flanged diaphragm seal pressure gauge. This specialized instrument integrates a diaphragm seal with a pressure gauge, offering several advantages, particularly in applications involving viscous, corrosive, or high-purity fluids.

What is a Diaphragm Seal?

A diaphragm seal is a mechanical device that isolates the measurement element of a pressure gauge from the process media. It consists of a flexible diaphragm that deflects under pressure, transferring the force to the gauge mechanism while preventing direct contact with the fluid. This design is especially beneficial for fluids that can clog or corrode traditional gauges, thereby ensuring accurate readings over time.

The diaphragm is typically made from materials such as stainless steel, PTFE, or other elastomers, depending on the chemical properties of the process media. The choice of material is crucial, as it affects not only the seal’s longevity but also the effectiveness of the pressure measurement.

Importance of Customization

The term custom in custom flanged diaphragm seal pressure gauges indicates that these instruments can be tailored to meet specific industry needs. This may include customization of the flange connection, diaphragm material, and the overall size and design of the gauge. These adaptations are vital for fitting particular applications, such as high-pressure or high-temperature environments, or for accommodating unique piping configurations.

For example, in the food and beverage industry, manufacturers often require gauges that can withstand aggressive cleaning agents while maintaining hygienic standards. Custom diaphragm seals can be designed to handle these conditions without compromising the integrity of the pressure measurement.

Applications

Custom flanged diaphragm seal pressure gauges are widely used in various industries, including

1. Chemical Processing They measure pressures in corrosive environments, ensuring that measurement integrity is maintained despite exposure to aggressive chemicals. 2. Oil and Gas These gauges can withstand the harsh conditions of extraction and processing, providing reliable readings even in extreme environments.

custom flanged diaphragm seal pressure gauge

3. Pharmaceuticals In high-purity processes, any contamination must be avoided. Diaphragm seals help maintain clean and accurate pressure readings essential for product quality.

4. Food and Beverage Customization for hygiene and sanitation requirements is critical in this sector, where process reliability directly affects consumer safety.

5. Water Treatment They are used to measure pressures in systems that may contain various impurities or require rigorous maintenance, without the fear of clogging or corrosion.

Benefits of Using Custom Flanged Diaphragm Seal Pressure Gauges

1. Enhanced Accuracy By isolating the gauge from harsh conditions, these gauges provide more accurate and reliable measurements.

2. Longevity Their robust design and material choices allow for extended service life, reducing the need for frequent replacements.

3. Versatility Customization options mean they can be adapted for almost any application requirement, making them suitable for a wide range of industries.

4. Safety By preventing contact with hazardous materials, these gauges help ensure the safety of operators and the surrounding environment.

5. Reduced Maintenance Their design minimizes the wear and tear associated with traditional gauges exposed to aggressive media, leading to lower operational costs.

Conclusion

In summary, custom flanged diaphragm seal pressure gauges play an essential role in ensuring accurate pressure measurements in challenging industrial environments. Their unique design and the potential for customization make them preferred choices in sectors where traditional pressure gauges may fail. By investing in these specialized instruments, industries can enhance operational efficiency, maintain safety, and ensure consistent quality in their processes. As technology continues to advance, the adaptability and precision of these gauges are likely to improve even further, underpinning their value for critical applications.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025