Nov . 17, 2024 04:59 Back to list

Custom Span Differential Pressure Gauge for Accurate Measurement and Monitoring Solutions

Understanding Custom Span Differential Pressure Gauges

Differential pressure gauges are essential instruments in various industrial applications, measuring the difference in pressure between two points in a system. Among the different types available, custom span differential pressure gauges stand out due to their ability to be tailored to specific needs and conditions of a given application. This article will explore what custom span differential pressure gauges are, their benefits, and their applications.

A differential pressure gauge operates by comparing the pressure at two points. The resulting reading provides insight into flow rates, filter conditions, and other critical operational parameters. In many industrial processes, the ability to customize the gauge’s span — that is, the range of pressure it can accurately measure — is crucial. Custom span differential pressure gauges allow users to adjust their measurement range according to specific process requirements, enhancing accuracy and reliability.

One of the primary benefits of custom span differential pressure gauges is precision. Standard gauges may not accurately capture the variations in pressure that occur in specialized applications, leading to errors and inefficiencies. By adjusting the span, manufacturers can ensure that the gauge provides precise readings even at lower or higher pressures. This customization improves system performance, as operators can act on more reliable data, ensuring optimal conditions are maintained.

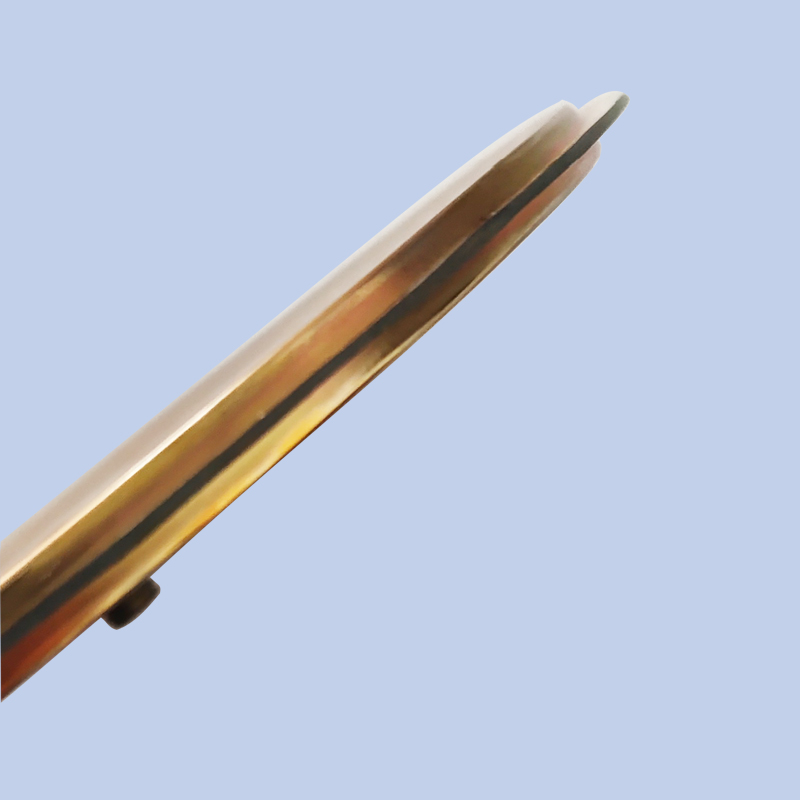

custom span differential pressure gauge

Moreover, the adaptability of custom span differential pressure gauges extends to various environments and conditions. Different industries, such as pharmaceuticals, food processing, and petrochemicals, have unique challenges that demand tailored solutions. For example, a pharmaceutical facility may require tight tolerances in pressure measurement to comply with strict regulations. Custom gauges can be designed to meet such specifications, ensuring quality control and regulatory compliance.

In addition, the construction materials of these gauges can be customized to withstand corrosive environments or extreme temperatures. This level of personalization protects the integrity of both the gauge and the system it monitors, significantly extending the lifespan of the equipment. Manufacturers often use robust materials like stainless steel, Teflon, or monel, which can handle aggressive substances and maintain accuracy over time.

Installation and maintenance can also be streamlined with custom span differential pressure gauges. By providing a gauge that fits perfectly within existing systems, companies can minimize downtime during installation. Additionally, when gauges are tailored to specific applications, the maintenance requirements may be reduced, as the equipment is less likely to encounter wear and tear from operating outside of its ideal range.

In conclusion, custom span differential pressure gauges offer significant advantages in accuracy, adaptability, and durability for a variety of industrial applications. By understanding the unique requirements of their processes, manufacturers can select or design gauges that meet their exact needs, leading to enhanced operational efficiency and safety. As industries continue to evolve, the demand for customized solutions like these gauges will undoubtedly grow, underscoring their importance in modern engineering and industrial practices.

-

HD Fire Pressure Gauges High Accuracy & Durable Solutions

NewsMay.28,2025

-

Custom Singles Capsule Systems Top Exporters & Factories

NewsMay.28,2025

-

Piston-Style Differential Pressure Gauges Precision & Durability

NewsMay.28,2025

-

WIKA Differential Pressure Gauge 700.04 High-Accuracy Industrial Measurement

NewsMay.28,2025

-

Precision Differential Pressure Gauge Factory Custom Solutions & OEM Services

NewsMay.27,2025

-

Pressure Diaphragm Capsule Elements High-Accuracy & Durable Solutions

NewsMay.27,2025