Jul . 28, 2024 11:37 Back to list

Diaphragm Seal ODM Pressure Gauge for Accurate Measurement and Reliable Performance in Various Applications

Understanding ODM Pressure Gauges with Diaphragm Seals A Focus on Wika Technology

In industrial applications where pressure measurement is crucial, choosing the right equipment is essential for ensuring accurate readings and reliability. One of the standout tools in this realm is the ODM pressure gauge equipped with diaphragm seals, particularly those manufactured by Wika, a renowned leader in the industry. This article explores the functionalities, advantages, and applications of these gauges, shedding light on why they are preferred in various sectors.

What is an ODM Pressure Gauge?

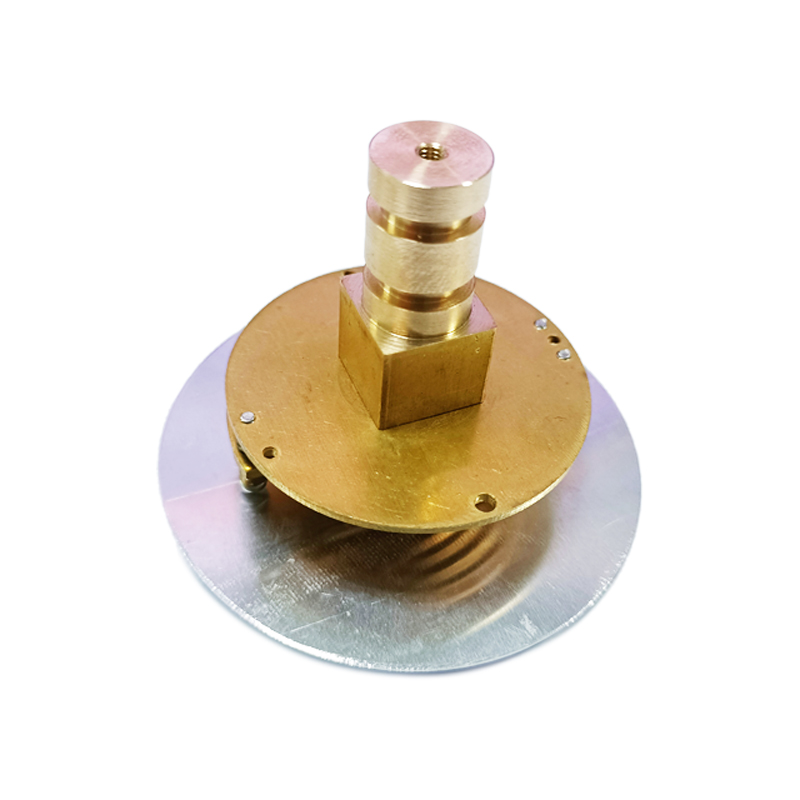

An ODM (Over-Range Detection Mechanism) pressure gauge is designed to measure the pressure of gases and liquids in a wide range of applications. The incorporation of a diaphragm seal allows it to handle corrosive or viscous fluids without compromising the integrity of the measurement. The diaphragm acts as a barrier between the process fluid and the measuring system, ensuring that the pressure reading remains accurate while also protecting the internal components of the gauge.

The Role of Diaphragm Seals

Diaphragm seals are crucial for extending the lifespan of pressure gauges, especially in harsh environments. They are made from materials that resist corrosion and wear, making them ideal for applications where the process fluid may be highly aggressive or contain particulates. Additionally, diaphragm seals can accommodate thermal expansion and minimize the risk of clogging, providing a more reliable means of measurement.

Wika's diaphragm seals are engineered with precision, ensuring that they deliver consistent and accurate readings even under fluctuating conditions. The seals are available in various materials, such as stainless steel and exotic alloys, to cater to different environmental and operational demands.

Advantages of Wika ODM Pressure Gauges

1. Durability Wika gauges are built to withstand tough conditions, including extreme temperatures and pressure variations. This robustness ensures that they can be relied upon in industries such as oil and gas, pharmaceuticals, and food processing.

odm pressure gauge with diaphragm seal wika

2. Accuracy The combination of ODM technology and diaphragm seals enhances the precision of pressure readings. This accuracy is vital in process control applications where minor deviations can lead to significant consequences.

3. Ease of Maintenance Wika designs its gauges with maintenance in mind. The ease of disassembly and the availability of replacement parts contribute to reduced downtime, which is a key factor for many operations.

4. Versatility These pressure gauges can be customized to fit a wide range of applications. Wika offers numerous models with varying pressure ranges, measurement units, and materials, allowing users to select the perfect gauge for their specific needs.

5. Safety By isolating the measuring mechanism from potentially hazardous materials, diaphragm seals enhance safety within industrial environments. This is particularly important in processes that handle toxic or explosive fluids.

Applications of ODM Pressure Gauges

The versatility of Wika ODM pressure gauges with diaphragm seals makes them suitable for numerous applications. In the petrochemical industry, they are used to monitor pipeline pressures and ensure the safe transfer of materials. In the food and beverage sector, maintaining the correct pressure during processing is vital to ensure product quality and safety, which these gauges can effectively facilitate. Additionally, in water treatment facilities, they provide essential measurements that contribute to optimal operation and compliance with regulatory standards.

Conclusion

In summary, Wika’s ODM pressure gauges with diaphragm seals represent a significant innovation in the field of pressure measurement. By marrying advanced technology with robust design, they provide reliability, accuracy, and safety for a multitude of applications. As industries continue to evolve, the demand for precise pressure measurement will undoubtedly grow, and tools like these will remain at the forefront, ensuring processes run smoothly and effectively.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025