Oct . 13, 2024 20:28 Back to list

diaphragm seal pressure gauge accuracy manufacturers

Understanding Diaphragm Seal Pressure Gauge Accuracy and Manufacturers

In industrial applications, pressure measurement is critical for ensuring safety and efficiency. Diaphragm seal pressure gauges are essential instruments designed to accurately measure pressure in various fluids and gases, particularly in harsh environments where standard gauges might fail. Understanding the accuracy of these gauges and the manufacturers behind them is paramount for operators seeking reliability and precision.

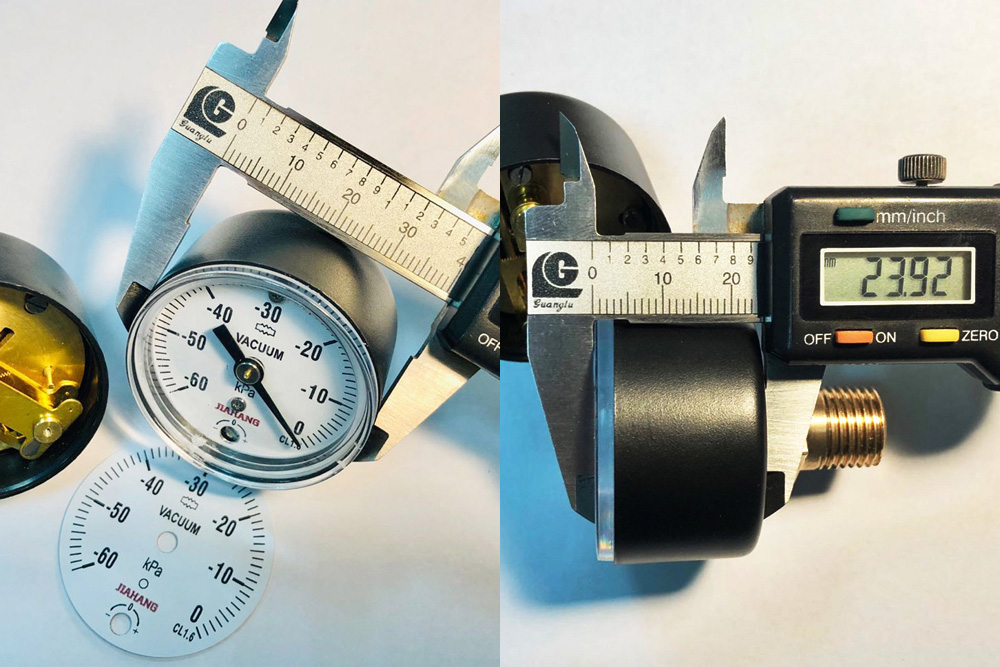

A diaphragm seal pressure gauge consists of a diaphragm that separates the process fluid from the gauge itself. This design serves dual purposes it protects the measurement system from corrosive or high-viscosity fluids and enhances accuracy by minimizing pressure fluctuations caused by pulsating media. The accuracy of these gauges is typically specified by the manufacturer and is influenced by several factors, including the materials used, the design of the diaphragm, and the calibration process.

Leading manufacturers of diaphragm seal pressure gauges often adhere to international standards such as ISO 9001 for quality management systems. This ensures that their products not only meet stringent safety and reliability criteria but also provide accurate measurements under varying conditions. Typically, high-quality gauges have an accuracy range of ±0.5% to ±1% of the full scale, although some specialized models may offer even tighter tolerances.

diaphragm seal pressure gauge accuracy manufacturers

In selecting a diaphragm seal pressure gauge, it is crucial to consider the specific application and the properties of the fluid being measured. Factors such as temperature, pressure range, and chemical compatibility can significantly impact both the accuracy and lifespan of the gauge. Many manufacturers provide comprehensive guidelines and technical support to help customers choose the right gauge for their needs.

Another important consideration is the ongoing maintenance and recalibration of diaphragm seal pressure gauges. Manufacturers often recommend regular checks to ensure continued accuracy, particularly in critical processes. This not only extends the life of the instrument but also ensures compliance with safety regulations.

Furthermore, leading manufacturers offer a range of diaphragm materials, including stainless steel, Hastelloy, and Teflon, catering to different environmental conditions and fluid types. The choice of the diaphragm material affects both the gauge’s durability and its performance in specific applications.

In conclusion, understanding the accuracy of diaphragm seal pressure gauges is essential for industries relying on precise pressure measurements. By choosing reputable manufacturers who prioritize quality and accuracy, operators can ensure that they select instruments that will perform reliably in demanding environments. Investing in high-quality diaphragm seal pressure gauges is not just a matter of meeting regulatory standards but also enhancing overall operational efficiency and safety.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025