Nov . 08, 2024 08:49 Back to list

Understanding the Functionality and Application of Diaphragm Pressure Gauges

Understanding Diaphragm Pressure Gauges Definition and Significance

Pressure measurement is critical in a wide range of industries, from manufacturing and medical applications to the oil and gas sector. Among the various instruments available for measuring pressure, diaphragm pressure gauges have emerged as a significant choice due to their reliability, accuracy, and adaptability. This article aims to elucidate what diaphragm pressure gauges are, how they function, and their various applications.

Definition of Diaphragm Pressure Gauges

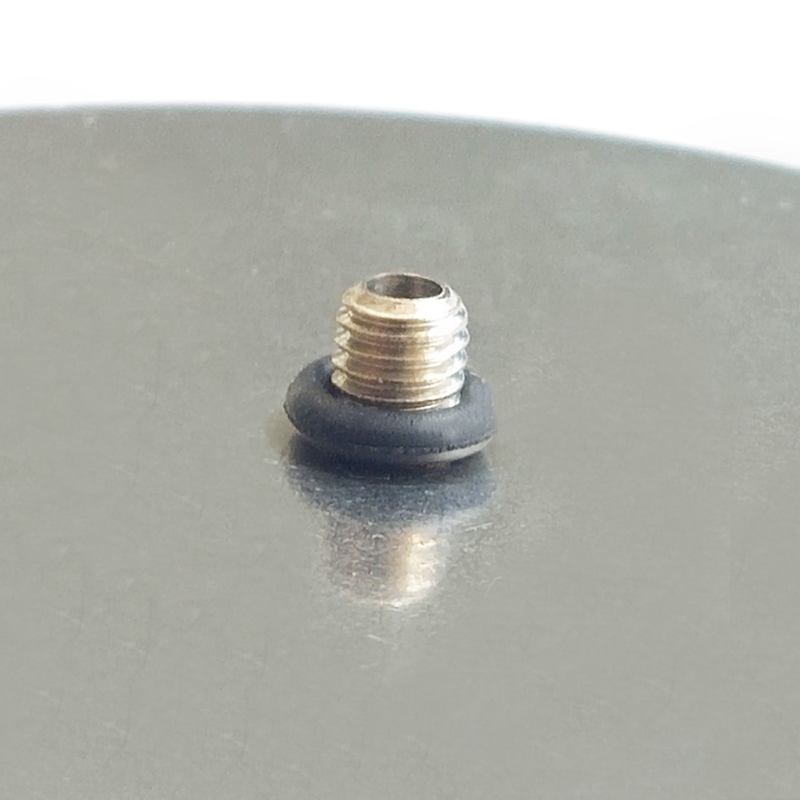

A diaphragm pressure gauge is a type of mechanical pressure gauge that employs a flexible diaphragm to measure pressure. This diaphragm, typically made from materials such as stainless steel, brass, or elastomers, is positioned between two compartments. One side is exposed to the pressure to be measured, while the other side is kept at a reference pressure, typically atmospheric pressure or a vacuum.

The primary mechanism involves the deformation of the diaphragm in response to pressure changes. When pressure is applied to the diaphragm, it bends or deflects. This deflection is then transmitted to a pointer through a mechanical linkage, which indicates the pressure level on a calibrated dial. The degree of deflection is proportional to the pressure exerted, making diaphragm gauges highly effective for precise pressure measurement.

How Diaphragm Pressure Gauges Work

The operation of a diaphragm pressure gauge can be summarized in several steps

1. Pressure Application The pressure to be measured acts on one side of the diaphragm. 2. Diaphragm Deformation The diaphragm flexes in response to the applied pressure. The amount of deformation is dependent on the magnitude of the pressure.

3. Mechanical Linkage The movement of the diaphragm is coupled to a mechanical linkage, which converts this movement into a rotational motion.

4. Pressure Reading The rotational motion moves a pointer across a calibrated scale, providing a visual representation of the pressure.

Diaphragm gauges can be designed to measure different types of pressure, including absolute pressure, gauge pressure, and differential pressure, making them versatile tools in various scenarios.

Applications of Diaphragm Pressure Gauges

Diaphragm pressure gauges find extensive use across multiple industries due to their reliability and efficacy

. Some of their notable applications includefamous pengertian diaphragm pressure gauge

1. Industrial Processes Commonly used in chemical plants, oil refineries, and manufacturing units to monitor process pressures. Their ability to withstand harsh environments makes them ideal for such applications.

2. Hydraulic Systems Used to measure pressures in hydraulic systems, which are critical for functioning machinery and equipment.

3. HVAC Systems Employed to monitor air and fluid pressures in heating, ventilation, and air conditioning systems, ensuring optimal operation and efficiency.

4. Medical Devices Utilized in various medical instruments that require precise pressure measurement, such as blood pressure monitors and respiratory devices.

5. Food and Beverage Industry Used in processes where pressure control is essential for maintaining product quality and safety, like in bottling or fermentation processes.

Advantages of Diaphragm Pressure Gauges

The popularity of diaphragm pressure gauges can be attributed to several advantages

- Accuracy They provide precise readings, which are crucial for maintaining operational efficiency.

- Durability With the right materials, diaphragm gauges can withstand extreme temperatures and corrosive environments.

- Low Maintenance The design of diaphragm gauges typically requires less maintenance compared to electronic pressure sensors, which can fail more easily.

- Cost-Effectiveness They are often more affordable than other types of pressure measuring devices, especially in applications where electronic devices may be too sensitive or expensive.

Conclusion

In summary, diaphragm pressure gauges play a vital role in accurate pressure measurement across various industries. Their fundamental design, which utilizes a flexible diaphragm to gauge pressure changes, offers numerous benefits, making them a preferred choice in many applications. Understanding how these gauges work and their significance in industrial processes helps businesses ensure efficiency, safety, and quality in their operations. As industries evolve, diaphragm pressure gauges will undoubtedly continue to be an integral part of pressure measurement technology.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025