Nov . 06, 2024 21:08 Back to list

Precision Differential Pressure Gauge Kit for Accurate Measurement and Monitoring

High Quality Differential Pressure Gauge Kit An Essential Tool for Precision Measurement

In the realm of industrial processes, maintaining optimal conditions is paramount. One of the key factors in achieving this goal is knowing the pressure differentials across various systems. This is where a high quality differential pressure gauge kit comes into play. Such kits are essential for ensuring efficient operation and safety in various applications, including HVAC systems, filter monitoring, and fluid dynamics.

What is a Differential Pressure Gauge?

A differential pressure gauge is a device that measures the difference in pressure between two points within a system. It can be used in numerous applications, ranging from measuring the airflow in cleanrooms to monitoring fluid levels in tanks. These gauges help operators and engineers assess the performance of their systems, ensuring that everything operates within the specified parameters.

The Importance of High-Quality Gauges

When it comes to differential pressure gauges, quality matters. High quality gauges provide accurate measurements, ensuring that critical processes do not go awry due to faulty readings. Furthermore, high-quality differential pressure gauge kits are constructed with durable materials, making them suitable for a variety of harsh environments. This durability minimizes the need for frequent replacements, reducing downtime and maintenance costs.

Key Features of a High Quality Differential Pressure Gauge Kit

When searching for a dependable differential pressure gauge kit, several features should be considered

1. Accuracy and Precision The foremost requirement of any pressure gauge is its ability to deliver accurate readings. High-quality kits typically have a high accuracy rating, ensuring that the measurements reflect true pressure differentials.

2. Calibration Good differential pressure gauge kits come pre-calibrated, with the option for users to recalibrate as needed. Regular calibration is essential to maintain measurement accuracy over time.

high quality differential pressure gauge kit

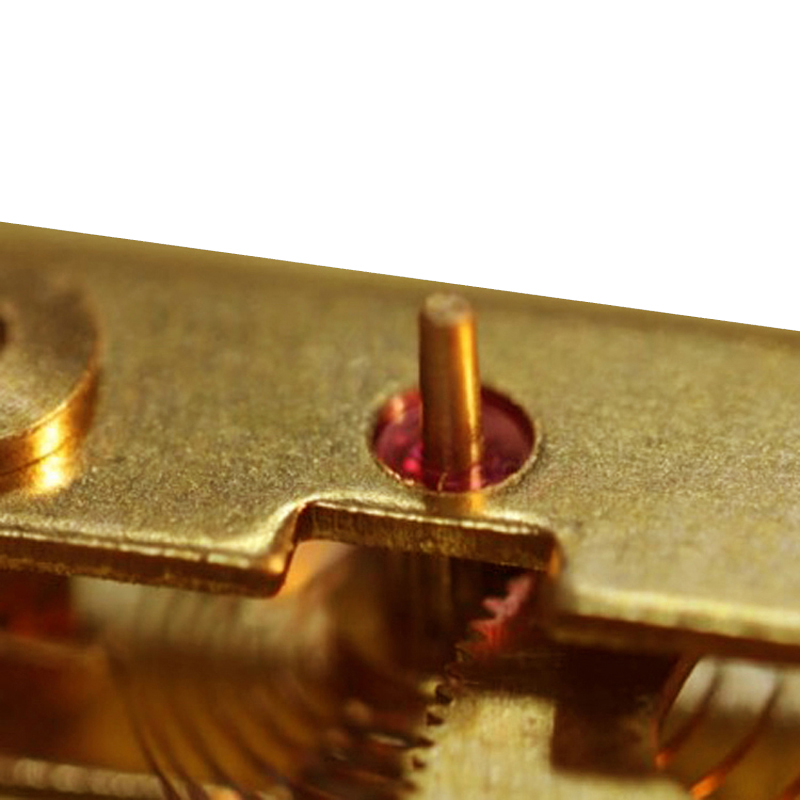

3. Robust Construction A high-quality kit is built to withstand demanding environments. Look for gauges made from durable materials such as stainless steel and those that possess certain environmental protective ratings, such as IP65 or higher.

4. Wide Measurement Range A versatile gauge can measure a wide range of pressures, accommodating various applications and processes.

5. User-Friendly Design Features such as easy-to-read dials, digital displays, and simple interface options significantly enhance usability, particularly in complex systems.

6. Complete Kit Components A comprehensive kit should include not only the gauge itself but also necessary fittings, connectors, and installation manuals, ensuring ease of setup.

Applications of Differential Pressure Gauge Kits

Differential pressure gauge kits are versatile tools with applications across numerous industries. For instance, in HVAC systems, they monitor pressure drops across filters, providing vital data that helps determine when filters need servicing or replacement. In pharmaceutical manufacturing, precise pressure measurements ensure that sterile environments are maintained, thereby safeguarding product integrity. Furthermore, in water treatment facilities, these gauges help monitor pressure levels to ensure efficient operation.

Conclusion

Investing in a high quality differential pressure gauge kit is an investment in accuracy, safety, and efficiency. These tools are indispensable for any industry that relies on pressure differentials to maintain optimal conditions. By choosing a robust and reliable kit, operators and engineers can ensure that their systems run efficiently, reduce downtime, and adhere to stringent safety standards.

In summary, whether you're looking to monitor air filters, control flows in chemical processes, or ensure optimal performance in HVAC systems, a high quality differential pressure gauge kit is essential. With the right features and build quality, these tools play a critical role in supporting operational goals and meeting industry requirements, making them a staple in any professional toolkit.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025