Nov . 18, 2024 08:03 Back to list

high quality spring diaphragm pressure gauge

Understanding High-Quality Spring Diaphragm Pressure Gauges

Pressure measurement is a critical aspect in various industries including manufacturing, oil and gas, food processing, and pharmaceuticals. One of the most reliable instruments for this purpose is the spring diaphragm pressure gauge. This article delves into the significance of high-quality spring diaphragm pressure gauges, their working principle, applications, and the factors to consider when selecting one.

What is a Spring Diaphragm Pressure Gauge?

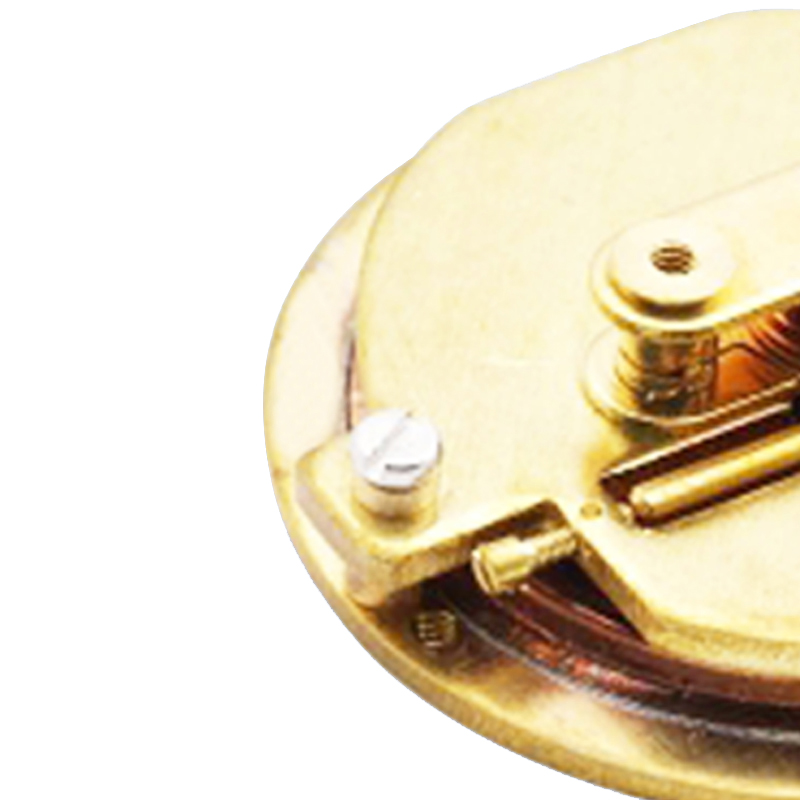

A spring diaphragm pressure gauge is a type of device used to measure the pressure of gases and liquids. It consists of a diaphragm—a flexible membrane—that separates the pressure measuring chamber from the external environment. When pressure is applied from the medium, the diaphragm deflects, and this movement is transmitted to a mechanical mechanism that translates the deflection into a readable measurement on a dial.

Working Principle

The working principle of a spring diaphragm pressure gauge is based on the deformation of the diaphragm under pressure. When the pressure inside the gauge increases, the diaphragm bends, causing a corresponding movement of a pointer attached to a spring mechanism. The degree of movement of this pointer correlates directly with the amount of pressure applied. Because of the sophisticated design, high-quality models can provide precise measurements, minimizing errors and enhancing reliability.

Importance of High Quality

High-quality spring diaphragm pressure gauges are vital for several reasons. First and foremost, precision is crucial. In industries where safety and efficiency are paramount, even small discrepancies in pressure readings can lead to catastrophic failures or inefficiencies. Additionally, high-quality gauges are constructed with durable materials that withstand harsh operating conditions such as extreme temperatures, corrosive environments, and high-pressure scenarios. This durability extends the lifespan of the gauge and reduces maintenance costs.

high quality spring diaphragm pressure gauge

High-quality gauges also incorporate advanced technologies that enhance accuracy and response time. Features such as anti-vibration mechanisms and shock-proof designs allow for consistent readings even in turbulent or fluctuating environments. Furthermore, quality manufacturers often provide calibration services, ensuring that the gauges maintain their accuracy over time.

Applications

Spring diaphragm pressure gauges find applications across various sectors. In the oil and gas industry, they are used for monitoring pressure in pipelines and storage tanks. In manufacturing, they play a crucial role in process controls, ensuring that machinery operates within safe pressure limits. The food processing industry relies on these gauges for maintaining safe pressure in boilers and sterilizers, while the pharmaceutical sector uses them to ensure proper conditions in drug production.

Selecting the Right Gauge

When choosing a spring diaphragm pressure gauge, it is essential to consider several factors. The expected pressure range, the type of fluid being measured (liquid or gas), and the operating environment all play a crucial role in determining the right gauge for your needs. Additionally, consider the gauge's accuracy rating, its connection type, and whether it features any additional functions such as electrical output for remote monitoring.

Conclusion

In conclusion, high-quality spring diaphragm pressure gauges are indispensable tools in various industries, providing critical pressure measurements needed for safe and efficient operations. Their design, durability, and precision make them suitable for a wide range of applications. When selecting a gauge, it is crucial to consider specific operational requirements to ensure optimal performance and reliability. By investing in a high-quality spring diaphragm pressure gauge, businesses not only enhance safety but also improve process efficiency and reduce maintenance costs, ultimately leading to a more sustainable operation.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025