Oct . 21, 2024 21:30 Back to list

Manufacturing Process of Isolating Diaphragm Pressure Gauges for Accurate Measurements

Understanding Isolating Diaphragm Pressure Gauges A Comprehensive Overview

Pressure measurement is an essential aspect of various industrial applications, from oil and gas to pharmaceuticals and water treatment. One instrument that plays a critical role in achieving accurate pressure readings is the isolating diaphragm pressure gauge. This article will explore what isolating diaphragm pressure gauges are, how they work, their advantages, and their applications in industry.

What is an Isolating Diaphragm Pressure Gauge?

An isolating diaphragm pressure gauge is a specialized device used to measure the pressure of fluids or gases. Its design incorporates a flexible diaphragm that separates the measuring medium from the gauge’s internal mechanism. This isolation is crucial when dealing with corrosive, viscous, or dirty fluids that could damage traditional pressure gauges or compromise their accuracy.

How Do Isolating Diaphragm Pressure Gauges Work?

The working principle of an isolating diaphragm pressure gauge involves the following key components

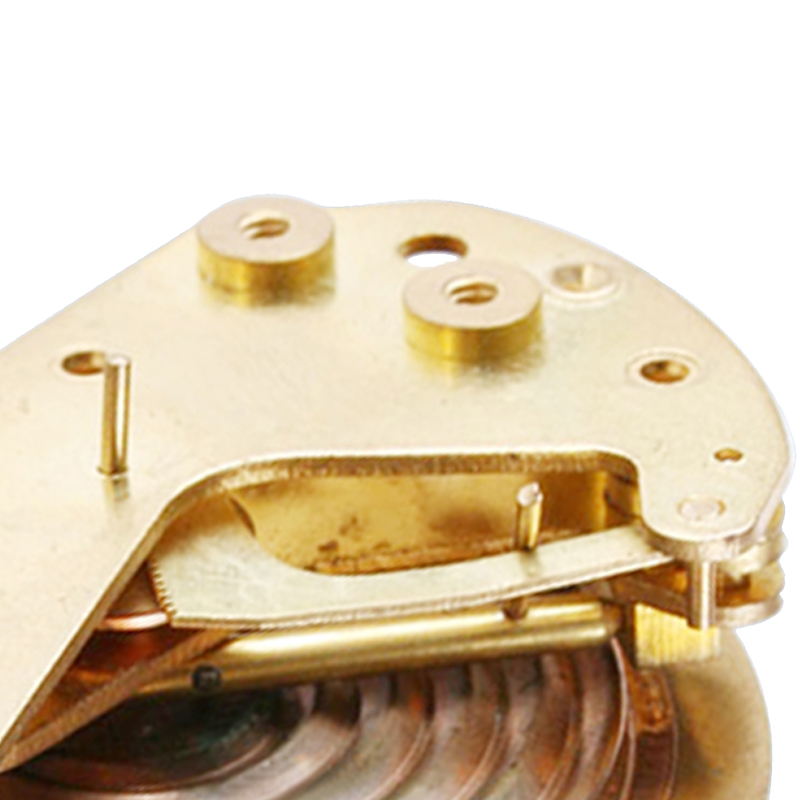

1. Diaphragm The core component is a thin, flexible membrane (diaphragm) that reacts to pressure changes. When pressure is applied to one side of the diaphragm, it deforms, causing a change in its curvature.

2. Separation Chamber The diaphragm isolates the measuring medium from the gauge internals, ensuring that only the diaphragm senses the pressure. The space on the other side of the diaphragm is often filled with a buffer fluid.

3. Transducer/Mechanism As the diaphragm moves in response to pressure changes, the movement is transferred to a mechanical transducer. This transducer can convert the displacement into an electrical signal (in electronic gauges) or drive a mechanical pointer on a dial.

4. Display The gauge finally displays the pressure reading, either digitally or through a traditional analog dial.

Advantages of Isolating Diaphragm Pressure Gauges

The isolating diaphragm pressure gauge offers several notable advantages

1. Protection from Corrosion By isolating the measuring system from the process fluid, these gauges protect delicate internal components from corrosive substances. This feature greatly enhances the lifespan of the gauge.

isolating diaphragm pressure gauge factory

2. Accuracy The diaphragm's sensitivity leads to high precision in pressure measurements, making it suitable for applications where accuracy is paramount.

3. Adaptability They can be customized to handle a wide range of pressures and temperatures, and they can be adapted for various mounting orientations.

4. Reduced Maintenance Since the diaphragm prevents direct contact with the measuring fluid, the probability of clogging or fouling is minimized. This leads to reduced maintenance and operational downtime.

5. Safety In applications where hazardous materials are involved, isolating diaphragm gauges help ensure that the medium does not leak into the environment.

Applications of Isolating Diaphragm Pressure Gauges

Isolating diaphragm pressure gauges are versatile instruments employed across various industries, including

1. Chemical Processing These gauges are invaluable in monitoring the pressure of reactive or corrosive chemicals, ensuring safe and efficient operations.

2. Pharmaceuticals In this sector, where precision and cleanliness are critical, isolating diaphragm gauges ensure accurate measurements while preventing contamination.

3. Oil and Gas Effective measurement in extraction, refining, and distribution processes is vital for safety and efficiency. Diaphragm gauges can withstand the harsh conditions found in this industry.

4. Water and Wastewater Treatment Monitoring pressure in treatment facilities is crucial for maintaining system integrity and operational effectiveness.

5. Food and Beverage Cleanliness and compliance with health regulations make isolating diaphragm pressure gauges an excellent choice for these industries.

Conclusion

In summary, isolating diaphragm pressure gauges are essential tools for achieving precise pressure measurements across various industrial applications. Their ability to isolate the measuring medium, combined with robustness and reliability, makes them indispensable in environments where traditional pressure gauges might fail. As industries strive for higher safety standards and increased efficiency, the adoption of isolating diaphragm pressure gauges is anticipated to grow, solidifying their place in modern measurement technology.

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025