Dic . 05, 2024 18:21 Back to list

OEM Diaphragm Seal Pressure Gauges for Accurate Measurement Solutions

Understanding OEM Pressure Gauges with Diaphragm Seals

Pressure measurement is a critical aspect in various industries, ranging from oil and gas to pharmaceuticals. One of the key components in ensuring accurate and reliable pressure measurement is the pressure gauge. Among the various types of pressure gauges available, OEM (Original Equipment Manufacturer) pressure gauges with diaphragm seals have gained significant popularity due to their robustness, versatility, and effectiveness in challenging environments.

What are OEM Pressure Gauges?

OEM pressure gauges are specifically designed by manufacturers to meet the unique requirements of their clients. Unlike standard pressure gauges, which may not cater to specific needs, OEM gauges are customized for particular applications. This customization can involve adjustments in dimensions, materials, and measurement ranges, ensuring that the pressure gauge aligns perfectly with the equipment it will be integrated into.

The Role of Diaphragm Seals

Diaphragm seals serve a crucial function in pressure measurement by separating the pressure sensing element from the process media. This is particularly important when dealing with corrosive, viscous, or high-temperature fluids that could damage a traditional pressure gauge.

The diaphragm seal system consists of a flexible diaphragm which responds to pressure changes in the process fluid. The mechanical movement of the diaphragm translates pressure changes into a measurable signal, which is then displayed on the gauge. This design not only protects the gauge but also enhances its accuracy and lifespan.

Advantages of Diaphragm Seals in Pressure Gauges

1. Protection Against Corrosive Media One of the primary advantages of using diaphragm seals is the protection they offer against corrosive substances. By isolating the pressure sensing element from harmful media, diaphragm seals prolong the life of the pressure gauge and maintain measurement accuracy.

2. Handling Viscous Fluids In processes involving viscous fluids, traditional pressure gauges may struggle to provide accurate readings due to clogging. Diaphragm seals minimize this risk since they can accommodate viscous substances without compromising performance.

3. Thermal Isolation In applications where the process media is subjected to high temperatures, diaphragm seals provide thermal isolation. This feature protects sensitive components within the gauge from thermal stress and ensures reliable operation under varying conditions.

4. Reduced Maintenance Since diaphragm seals keep the pressure sensing element insulated from the process media, the need for frequent maintenance is significantly reduced. This not only lowers operational costs but also improves system reliability.

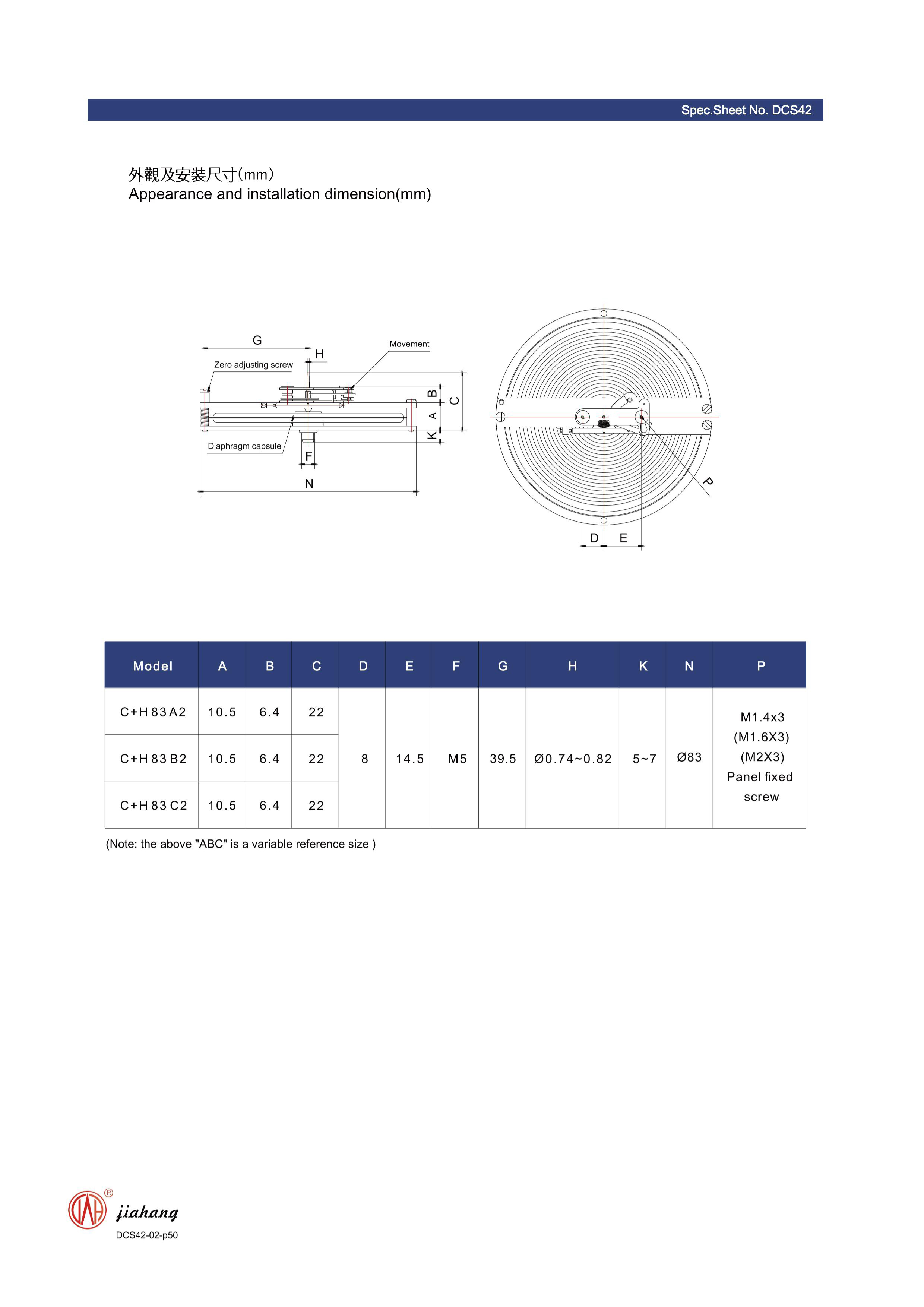

oem pressure gauges with diaphragm seals

Applications of OEM Pressure Gauges with Diaphragm Seals

The versatility of OEM pressure gauges with diaphragm seals makes them suitable for a wide range of applications. They are frequently used in

- Chemical Processing To measure the pressure of reactive and corrosive chemicals safely. - Oil and Gas In environments where pressure readings are critical to operational safety and efficiency. - Food and Beverage To ensure safe processing conditions without contaminating food products. - Pharmaceuticals In sterile environments where contamination must be avoided.

Selecting the Right OEM Pressure Gauge with Diaphragm Seal

When choosing an OEM pressure gauge with diaphragm seal, several factors should be considered

1. Material Compatibility Ensure that the diaphragm material is compatible with the process fluid. Common materials include 316 stainless steel, Hastelloy, and PTFE.

2. Pressure Range Select a gauge that accommodates the expected pressure range of your application.

3. Temperature Tolerance Verify that the gauge can withstand the temperature fluctuations present in your processes.

4. Installation Considerations Assess the installation environment and choose a gauge design that fits the available space and mounting requirements.

5. Calibration Needs Determine if the gauge requires calibration and how often to ensure ongoing accuracy.

Conclusion

OEM pressure gauges with diaphragm seals offer a reliable and effective solution for a variety of industries demanding precision in pressure measurement. By protecting the sensor from harsh environments and enabling accurate readings regardless of media characteristics, these specialized gauges enhance both efficiency and safety. Choosing the right OEM gauge for your application involves careful consideration of materials, pressure ranges, and installation specifics, ensuring you have the best possible tool for your pressure measurement needs.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025