Dic . 12, 2024 11:32 Back to list

spring diaphragm pressure gauge product

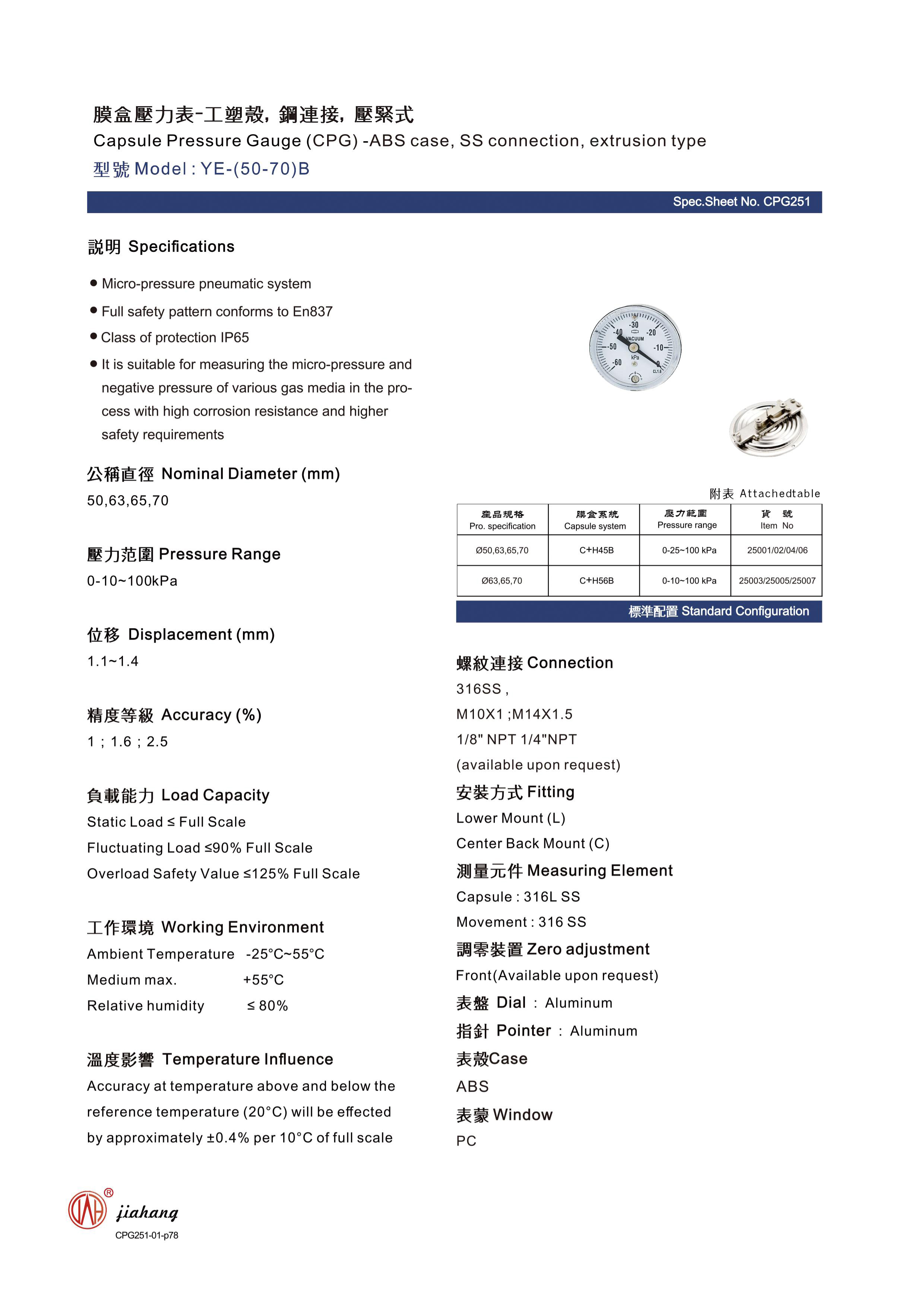

Understanding Spring Diaphragm Pressure Gauges A Comprehensive Overview

Pressure measurement is a critical aspect of various industrial processes and applications, ensuring safety, efficiency, and product quality. Among the myriad of tools available for this task, the spring diaphragm pressure gauge stands out for its accuracy, reliability, and ease of use. This article explores the functionality, applications, and benefits of spring diaphragm pressure gauges, shedding light on why they are a preferred choice in many industries.

What Is a Spring Diaphragm Pressure Gauge?

A spring diaphragm pressure gauge is an instrument that measures the pressure of gases or liquids in a given system. It operates on the principle of a diaphragm, a flexible membrane that deflects under pressure. This deflection is then converted into a readable value displayed on the gauge dial. The design typically includes a spring that applies a counterforce to the diaphragm, ensuring that the gauge can accurately measure varying pressure levels.

How Does It Work?

The core mechanism of the spring diaphragm pressure gauge involves a diaphragm sealed in a pressure chamber. When pressure is applied, the diaphragm flexes, causing a change in shape. This deformation is transmitted through a system of levers or linkages connected to a measuring spring. The spring's tension opposes the diaphragm's deflection, and the resulting movement is translated into a rotational movement of the gauge needle on a calibrated scale, indicating the pressure level.

Key Features

1. High Precision Spring diaphragm gauges are known for their exceptional accuracy. They can measure pressures ranging from very low to very high, depending on the design and materials used.

2. Durability Constructed from robust materials, these gauges can withstand harsh operating conditions, making them suitable for industrial environments.

3. Low Maintenance With fewer moving parts compared to other types of gauges, spring diaphragm pressure gauges require minimal maintenance, promoting reliability over time.

4. Versatility These gauges can be used for various applications, including but not limited to hydraulic systems, pneumatic systems, and even in the food and beverage industry for monitoring pressures accurately during processing.

spring diaphragm pressure gauge product

Applications of Spring Diaphragm Pressure Gauges

The versatility of spring diaphragm pressure gauges means they find use in numerous fields

- Oil and Gas Industry Monitoring pressure in pipelines and storage tanks is crucial for safety and operational efficiency. Spring diaphragm gauges provide reliable measurements that help prevent leaks and equipment failures.

- Automotive Sector These gauges are used in engine testing to measure fuel and oil pressures, contributing to vehicle performance assessments.

- Pharmaceutical Manufacturing In environments where sterilization is essential, spring diaphragm pressure gauges monitor and control the pressure of various gases and liquids, ensuring product integrity.

- Water Management Similar gauges are employed in municipal water systems to monitor the pressure in pipelines, ensuring consistent water supply and detecting leaks promptly.

Benefits of Using Spring Diaphragm Pressure Gauges

1. Cost-Effective The long lifespan and low maintenance needs of spring diaphragm gauges make them a cost-effective solution for many industries.

2. Ease of Calibration Compared to other types of pressure measurement devices, calibration of spring diaphragm gauges is straightforward, allowing for quick adjustments and setups.

3. User-Friendly The design of these gauges typically includes easy-to-read dials and scales, making them accessible even to those with limited technical knowledge.

Conclusion

Spring diaphragm pressure gauges are indispensable tools across a variety of industries where accurate pressure measurement is essential. Their precision, durability, and versatility ensure they meet the demands of modern applications. As industries continue to evolve, the role of innovative measurement tools like spring diaphragm pressure gauges will undoubtedly remain critical in promoting safety, efficiency, and productivity. Investing in quality pressure measurement devices not only enhances operational effectiveness but also aligns with best practices in maintaining equipment and processes.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025