Ago . 21, 2024 10:50 Back to list

Suppliers of Diaphragm Seal Differential Pressure Gauges for Accurate Measurements

Differential Pressure Gauge with Diaphragm Seal A Comprehensive Overview

In various industrial applications, monitoring pressure differences is crucial for ensuring operational efficiency, safety, and reliability. One of the most effective tools for this purpose is the differential pressure gauge, particularly those equipped with a diaphragm seal. This article explores the significance of differential pressure gauges with diaphragm seals, their applications, advantages, and the leading suppliers in the market.

Understanding Differential Pressure Gauges

A differential pressure gauge measures the difference in pressure between two points within a system. This measurement is vital in numerous processes, including fluid dynamics, HVAC systems, chemical processing, and filtration systems. The accurate monitoring of pressure differentials allows operators to detect changes in system performance, troubleshoot issues, and ensure that processes operate within safe parameters.

The Role of Diaphragm Seals

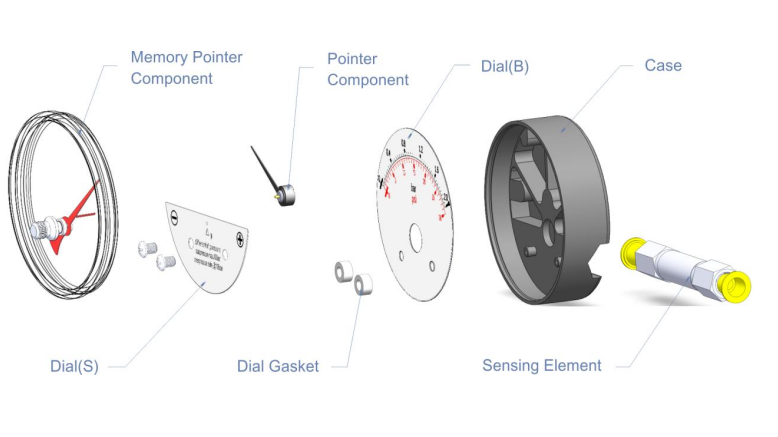

Diaphragm seals are essential components of differential pressure gauges, particularly in scenarios where the fluids being measured are corrosive, viscous, or contain solid particles. A diaphragm seal isolates the gauge from the process media, protecting it from damage while enabling accurate measurements. This barrier is typically made from materials that resist wear and corrosion, such as stainless steel or specialized polymers, ensuring longevity and reliability in harsh environments.

Applications of Differential Pressure Gauges with Diaphragm Seals

Differential pressure gauges with diaphragm seals find applications across a wide range of industries, including

1. Chemical Processing In chemical plants, these gauges monitor pressure differentials in reactors, tanks, and pipelines, helping to maintain optimal operating conditions.

2. Oil and Gas In the oil and gas industry, they are used to measure pressures in wells, separators, and refineries, ensuring safe extraction and processing of hydrocarbons.

differential pressure gauge with diaphragm seal suppliers

4. HVAC Systems In heating, ventilation, and air conditioning systems, these gauges help regulate airflow and pressure, ensuring energy efficiency and occupant comfort.

Advantages of Using Diaphragm Seals

The incorporation of diaphragm seals in differential pressure gauges offers several noteworthy benefits

- Protection from Corrosion By isolating the gauge from harsh media, diaphragm seals prevent corrosion and extend the lifespan of the gauge.

- Accurate Measurements Seals help prevent clogging and contamination, resulting in accurate and reliable pressure readings.

- Reduced Maintenance With improved protection against the process media, there is a reduced need for frequent maintenance, leading to lower operational costs.

- Versatility Diaphragm seals can be designed to accommodate various media types, including toxic and viscous substances, making them suitable for diverse applications.

Leading Suppliers in the Market

Several reputable manufacturers and suppliers specialize in differential pressure gauges with diaphragm seals. Companies such as Ashcroft, WIKA, and Brooks Instruments are known for their high-quality products and innovative solutions. These suppliers offer a variety of options tailored to different industrial needs, ensuring customers can find the right gauge for their specific applications.

Conclusion

Differential pressure gauges with diaphragm seals are indispensable tools for industries that require precise monitoring of pressure differentials. Their robust design, coupled with the protective capabilities of diaphragm seals, ensures accurate measurements while safeguarding the gauges from adverse conditions. With numerous applications across various sectors and a range of suppliers available, investing in these instruments is essential for maintaining efficiency and safety in industrial operations.

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025