Sep . 06, 2024 09:56 Back to list

Wika Differential Pressure Gauge - Reliable Measurement Solutions

Understanding Wika Differential Pressure Gauges A Look at Four Key Factories

Differential pressure gauges are essential instruments in various industrial applications, providing critical data to monitor fluid dynamics in pipes and process equipment. Among the leading manufacturers in this field is Wika, a company renowned for its high-quality measurement solutions. This article explores the significance of Wika differential pressure gauges, focusing on four key factories that contribute to their reputation for excellence.

1. Functional Design and Precision

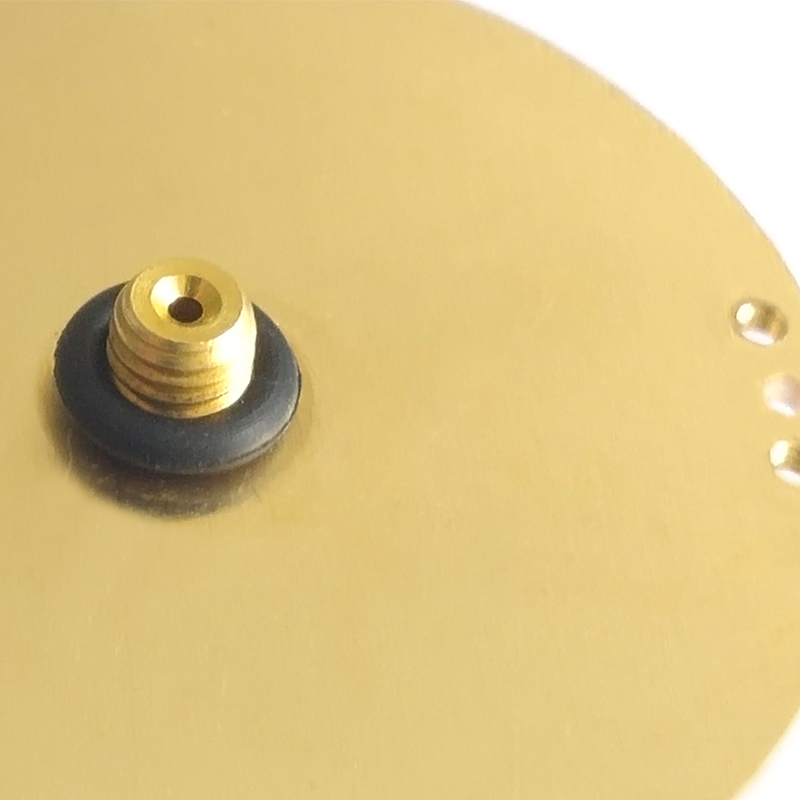

Wika's differential pressure gauges are designed for accuracy and durability, catering to various sectors, including oil and gas, water treatment, and pharmaceutical industries. The gauges operate based on the difference in pressure between two points in a system, allowing operators to monitor flow rates and detect issues such as blockages or leaks. The precision offered by Wika gauges is a result of advanced manufacturing techniques adopted in their factories, which ensure tight tolerances and reliable performance.

2. Quality Control and Assurance

Quality control is paramount in the production of differential pressure gauges, and Wika takes this aspect seriously. Each factory implements stringent quality assurance protocols to guarantee that every instrument leaving their assembly lines meets the highest standards. This involves rigorous testing procedures, including calibration and environmental testing, which not only verify functionality but also ensure long-term reliability in demanding conditions.

wika differential pressure gauge 4 factories

3. Technological Innovation

Wika continuously invests in research and development across its manufacturing facilities. This commitment to innovation has led to the introduction of smart differential pressure gauges equipped with digital interfaces and communication capabilities. These advancements allow for real-time data monitoring and integration with other systems, enhancing the overall efficiency of industrial operations. By keeping pace with technology trends, Wika remains a step ahead of competitors, ensuring that their products meet the evolving needs of the industry.

4. Global Reach and Local Expertise

With factories located in various parts of the world, Wika benefits from a combination of global reach and local expertise. Each facility is staffed by skilled professionals familiar with regional requirements and standards. This localized knowledge enables Wika to tailor its products to specific market needs while ensuring compliance with international regulations. The result is a comprehensive range of differential pressure gauges that cater to diverse applications worldwide.

Conclusion

Wika differential pressure gauges stand out for their exceptional quality, precision, and innovative design. The concerted efforts of their factories worldwide assure customers that they are investing in reliable, high-performing instruments. As industries continue to evolve, Wika’s commitment to excellence will undoubtedly play a pivotal role in shaping the future of pressure measurement technology.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025