Oct . 21, 2024 09:22 Back to list

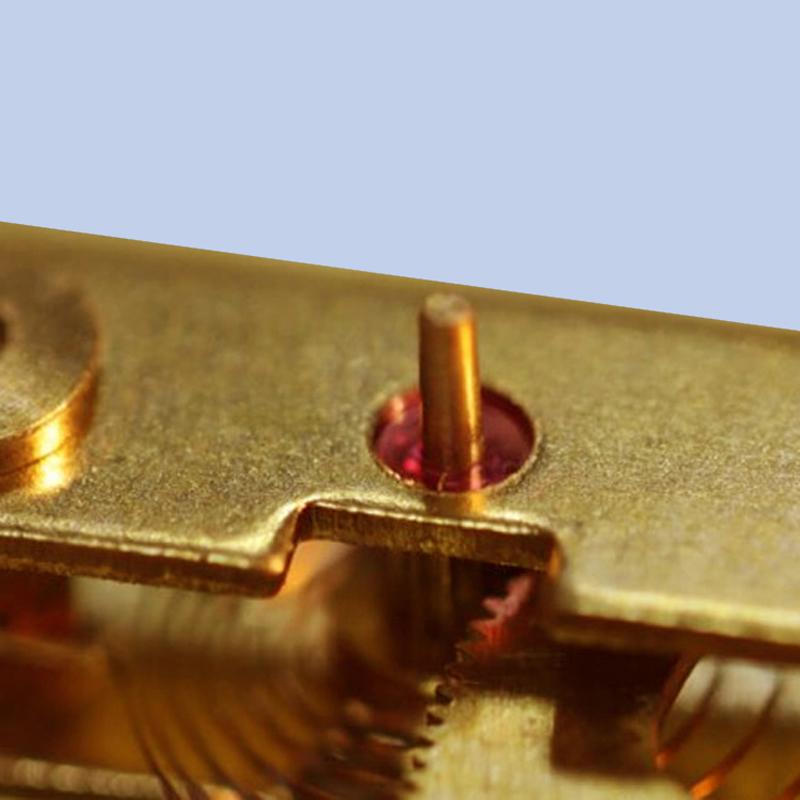

Carbon Dioxide Fire Extinguisher Pressure Gauge Manufacturing Process and Quality Standards

Understanding the Pressure Gauge of a Carbon Dioxide Fire Extinguisher

Carbon dioxide (CO2) fire extinguishers are essential safety devices commonly used in various environments, including homes, offices, and industrial settings. One crucial component of these extinguishers is the pressure gauge, which plays a vital role in ensuring the effective operation of the device. Understanding how the pressure gauge functions, what it indicates, and the importance of regular maintenance can greatly enhance fire safety protocols.

What is a CO2 Fire Extinguisher?

A carbon dioxide fire extinguisher is designed to combat Class B (flammable liquids) and Class C (electrical) fires. It works by displacing oxygen in the vicinity of the fire, effectively starving it of the element it needs to continue burning. CO2 extinguishers are particularly advantageous because they leave no residue, making them ideal for use in areas containing sensitive equipment, such as offices and laboratories.

The Role of the Pressure Gauge

The pressure gauge on a CO2 fire extinguisher serves as a vital indicator of the extinguisher's readiness for use. Typically located on the top of the cylinder, the gauge features a needle that points to a color-coded scale—usually marked in the green, yellow, and red zones.

carbon dioxide fire extinguisher pressure gauge factory

- Green Zone This indicates that the extinguisher is fully charged and ready for use. A reading in this zone reflects proper pressure levels, suggesting that the extinguisher can effectively displace oxygen when activated. - Yellow Zone This zone warns that the extinguisher is partially charged. While it may still function, its effectiveness could be compromised, and it may not perform optimally in an emergency situation. - Red Zone A reading in this area signals that the extinguisher is either over-pressurized or under-pressurized, suggesting a potential malfunction. An extinguisher in this state should be serviced immediately, as it may not work correctly when needed.

Importance of Regular Maintenance

Regular maintenance of carbon dioxide fire extinguishers is crucial for fire safety. The pressure gauge should be checked at least once a month to ensure that it remains in the green zone. Additionally, it is recommended that a qualified technician performs a thorough inspection at least once a year. During this inspection, the technician can check for leaks, verify the integrity of the cylinder, and ensure that all components, including the nozzle and pressure gauge, are functioning properly.

In addition to regular checks, it is essential to keep in mind the lifespan of fire extinguishers. Most CO2 extinguishers come with a service life of about 5 to 15 years, depending on the manufacturer. After this period, they should be replaced or reconditioned. Always refer to the manufacturer's guidelines for specific recommendations related to servicing and replacement.

Conclusion

The pressure gauge on a carbon dioxide fire extinguisher is more than just a simple indicator; it is a critical component that ensures the extinguisher will operate effectively in a fire emergency. By understanding its function and maintaining the extinguisher properly, individuals and organizations can significantly enhance their fire safety measures. A well-maintained CO2 extinguisher, with a needle firmly in the green zone, provides peace of mind, knowing that you are prepared to respond to a fire quickly and effectively. Remember, when it comes to fire safety, preparation is key.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025