Nov . 14, 2024 09:02 Back to list

cryogenic differential pressure gauge factory

Cryogenic Differential Pressure Gauge Essential Tools for Precision Measurement

In industries that rely heavily on cryogenic processes, accurate measurement of pressure differentials is crucial. Cryogenic differential pressure gauges serve as vital instruments, ensuring safety and efficiency in environments with extremely low temperatures, such as those found in liquefied natural gas (LNG) facilities, cryogenic storage systems, and superconducting technologies.

These specialized gauges are designed to provide reliable readings under conditions where conventional gauges might fail. They can accurately measure the pressure difference between two points in a system, which is essential for monitoring fluid levels, detecting leakage, and managing flow rates. This not only helps in maintaining process integrity but also plays a significant role in enhancing overall operational efficiency.

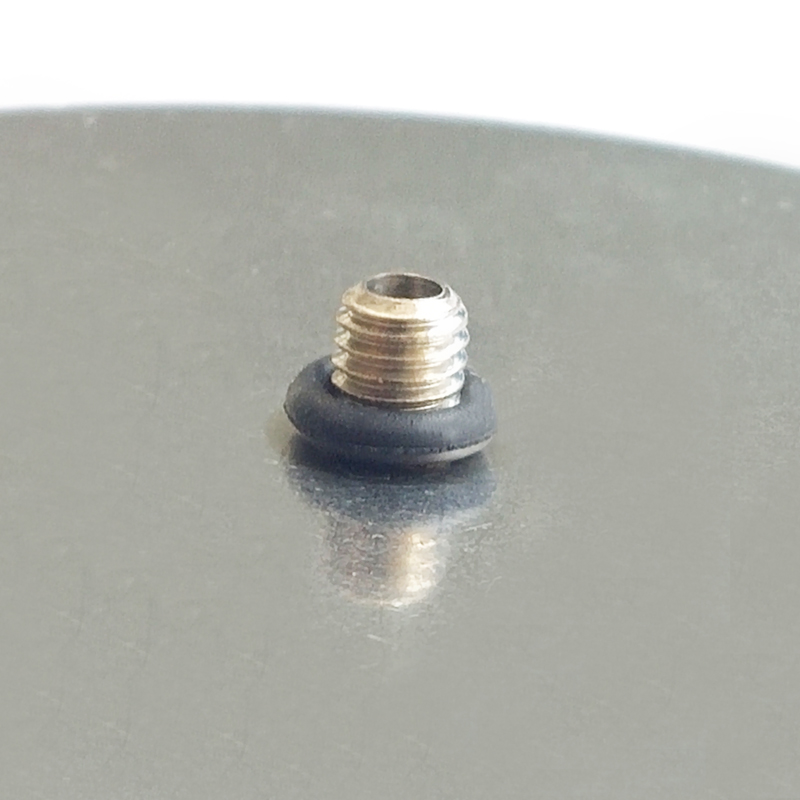

Manufacturers of cryogenic differential pressure gauges utilize advanced materials and technologies to ensure performance even in extreme conditions. The gauges are often constructed from stainless steel or other non-corrosive materials that can withstand the effects of low temperatures. Additionally, the sensing elements are meticulously designed to minimize thermal effects while maximizing sensitivity to pressure changes.

cryogenic differential pressure gauge factory

Quality control is paramount; therefore, leading factories implement rigorous testing and calibration processes. Each gauge undergoes extensive examination to confirm its accuracy and responsiveness. This commitment to quality guarantees that the gauges perform reliably in applications ranging from aerospace and medical technologies to energy production and research laboratories.

Furthermore, with the growing emphasis on sustainable energy solutions, the demand for cryogenic technologies continues to rise. Consequently, cryogenic differential pressure gauge manufacturers are innovating to develop smarter and more efficient measuring devices. Many gauges now feature digital interfaces, allowing users to monitor data in real-time and integrate with automated systems, enhancing user experience and operational insights.

In conclusion, cryogenic differential pressure gauges are indispensable in various high-stakes applications requiring precise pressure measurements. As technology evolves, so too will the capabilities of these instruments. Manufacturing excellence and a commitment to innovation will ensure that these critical components continue to meet the demands of the ever-evolving cryogenic landscape, enabling safer and more efficient operations across multiple sectors.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025