Sep . 28, 2024 13:57 Back to list

Custom High-Precision Pressure Gauge for Accurate Measurement Solutions

The Importance of Custom Precision Pressure Gauges in Industrial Applications

In various industrial sectors, accurate measurement of pressure is critical to ensure safety, efficiency, and reliability. Pressure gauges are essential instruments that provide real-time readings of pressure levels in different applications, ranging from oil and gas to pharmaceuticals. Among the various types of pressure gauges available, custom precision pressure gauges play a significant role in meeting the specific needs of diverse industries. Understanding their importance can lead to improved operations and enhanced safety protocols.

Understanding Custom Precision Pressure Gauges

Custom precision pressure gauges are tailored instruments designed to meet specific customer requirements. These gauges are not standard off-the-shelf products; instead, they are engineered to accommodate unique parameters like pressure ranges, material composition, size, accuracy, and display type. Customization ensures that the gauges provide precise measurements in environments that demand high performance under challenging conditions, such as extreme temperatures, corrosive substances, or high-pressure systems.

Key Features and Benefits

1. Enhanced Accuracy and Reliability One of the primary advantages of custom precision gauges is their superior accuracy. Industries that rely on high-pressure measurements cannot afford inaccuracies, as even small deviations can lead to significant safety hazards or operational inefficiencies. Custom gauges are calibrated to meet strict precision standards, ensuring reliable data collection.

2. Material Selection Different industries require different materials for pressure gauges due to environmental factors. For example, the food and beverage industry demands stainless steel to comply with hygiene standards, while the chemical processing industry might require gauges made from exotic alloys to withstand corrosive agents. Custom precision gauges facilitate the choice of materials that suit specific applications.

3. Adaptability to Unique Conditions Every industry has its set of conditions that may not align with standard products. Custom gauges can be designed to function optimally in extreme conditions, such as high temperatures or vacuum settings, thereby enhancing the operational scope of machinery and equipment.

4. Enhanced Safety Features Safety is paramount in industries that deal with pressurized systems. Custom precision pressure gauges can be equipped with features like integrated safety valves or burst disk mechanisms, providing an additional layer of protection against pressure buildup or system failures.

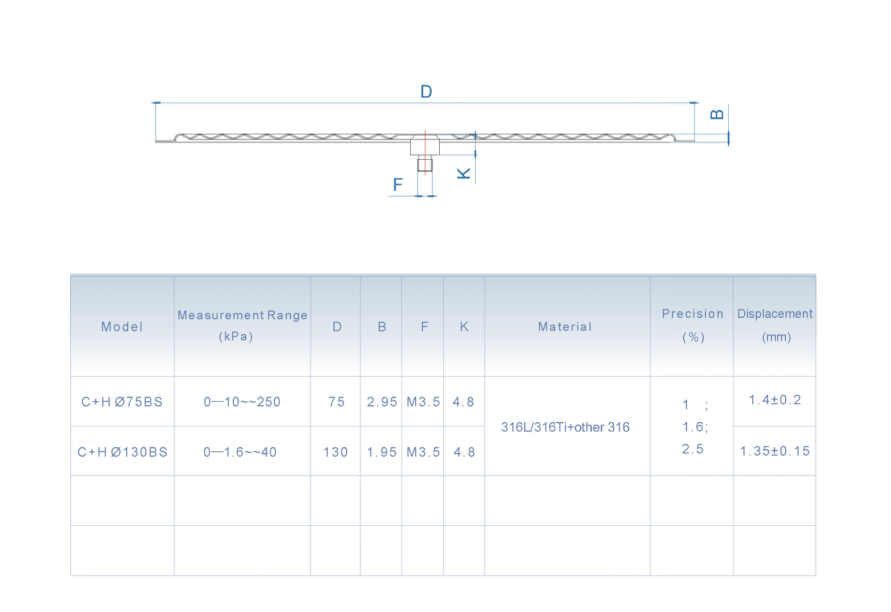

custom precision pressure gauge

5. Improved Integration Many industries utilize automated systems where pressure gauges must work seamlessly with other instruments. Custom solutions can be designed to integrate perfectly with existing systems, including digital displays and data loggers, allowing for real-time monitoring and management of pressure levels.

Applications Across Industries

Custom precision pressure gauges find countless applications across a variety of sectors

- Oil and Gas In exploration and extraction activities, accurate pressure monitoring is essential for safe operations. Custom gauges help manage well pressure, ensuring the integrity of pipelines and preventing blowouts.

- Aerospace The aerospace sector uses precision gauges to monitor fuel and hydraulic systems, where even minor pressure discrepancies can lead to catastrophic failures. Custom designs are adapted to meet stringent industry regulations.

- Pharmaceuticals In the pharmaceutical industry, sterilization processes require precise pressure control. Custom pressure gauges ensure the effectiveness of sterilization cycles, contributing to product safety and compliance with health regulations.

- Manufacturing In manufacturing settings, pressure is crucial for processes like mold injection and coating. Customized gauges can provide real-time monitoring, enhancing production quality and reducing waste.

Conclusion

The role of custom precision pressure gauges cannot be overstated. These specialized instruments ensure accurate pressure measurement, which is vital for safe and efficient operations across diverse industries. By providing tailored solutions, companies can significantly enhance their operational capabilities, ensure regulatory compliance, and fortify their safety measures. As industries continue to evolve, the demand for custom precision pressure gauges will undoubtedly grow, underscoring their importance in modern industrial applications. Whether you are in oil and gas, pharmaceuticals, or aerospace, investing in custom precision gauges is a crucial step toward operational excellence and safety.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025