Nov . 19, 2024 03:50 Back to list

custom wika diaphragm seal type pressure gauge

Understanding Custom Wika Diaphragm Seal Type Pressure Gauges

Pressure measurement is a critical component in many industrial processes, and selecting the right kind of pressure gauge is essential to ensure accuracy and reliability. One of the top contenders in the field of pressure measurement is the Wika diaphragm seal type pressure gauge. This article will delve into the features, advantages, and applications of these sophisticated devices, particularly in custom configurations.

What is a Diaphragm Seal Type Pressure Gauge?

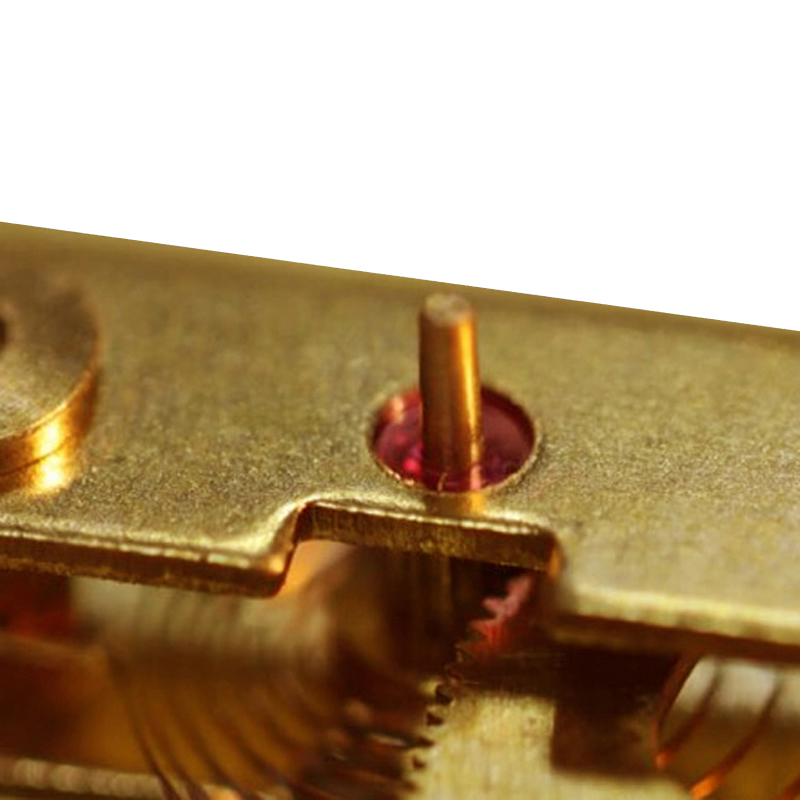

A diaphragm seal type pressure gauge is designed to measure the pressure of liquids and gases that might adversely affect traditional pressure gauges. This is often necessary in industries where corrosive, viscous, or high-temperature media are involved. The diaphragm seal acts as a barrier between the pressure medium and the measuring system, thus protecting the pressure gauge from potential damage.

Wika, a leading manufacturer in the field, offers a range of custom diaphragm seal type pressure gauges tailored to meet specific industry requirements. These custom gauges are engineered to handle various mediums, environmental conditions, and operational demands.

Key Features

1. Custom Design Wika understands that one size does not fit all. Their ability to provide custom-engineered diaphragm seal pressure gauges means that businesses can specify the materials, sizes, and calibration options that best suit their applications.

2. Superior Protection The diaphragm seal provides a robust safety barrier, minimizing the risk of contamination or damage to the pressure sensing element. This is particularly crucial in food, pharmaceutical, and chemical industries, where maintaining the purity of the medium is essential.

3. Temperature Resistance Custom diaphragm seals can be designed to withstand extreme temperatures, making them suitable for high-heat applications. This feature is critical in industries like oil and gas, where temperature fluctuations are common.

4. Easy Maintenance With Wika’s custom solutions, maintenance becomes simpler. Many designs allow for easy disassembly, streamlining the cleaning process and ensuring minimal downtime for facilities.

5. Versatility These gauges can be equipped to measure a wide range of pressures, from vacuum to high-pressure environments. Depending on the application, Wika can tailor the gauge to ensure accuracy across the desired measurement range.

custom wika diaphragm seal type pressure gauge

Advantages of Using Wika Diaphragm Seal Type Pressure Gauges

1. Accuracy and Reliability The design of diaphragm seal gauges leads to enhanced accuracy. The gauges can provide consistent and reliable readings, which is crucial for maintaining operational efficiency and safety standards.

2. Application-Specific Solutions Customization allows users to adapt their pressure gauge to the unique conditions of their environment. Whether it's dealing with high-corrosive chemicals or varying pressure levels, Wika's offerings can meet specific operational challenges.

3. Durability The materials used in Wika's diaphragm seals are selected for their durability and resistance to wear. This prolongs the lifespan of the pressure gauge, resulting in lower replacement costs over time.

4. Improved Safety In many industrial processes, a faulty pressure gauge can lead to dangerous situations. By utilizing robust diaphragm seal technology, users are better protected against pressure surges and potential ruptures.

Applications

Wika diaphragm seal type pressure gauges are commonly used in a wide range of industries, including

- Chemical Processing Handling corrosive substances safely and accurately. - Pharmaceuticals Maintaining the purity and quality standards necessary for production. - Food and Beverage Ensuring hygienic conditions and accurate process monitoring. - Oil and Gas Monitoring conditions in harsh environments.

Conclusion

In the realm of pressure measurement, Wika’s custom diaphragm seal type pressure gauges are invaluable tools for many industries. Their combination of customization, durability, and accuracy ensures that they can meet the specific needs of various applications. By investing in a diaphragm seal type pressure gauge, industries can enhance their operational efficiency while ensuring safety and reliability in their processes.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025